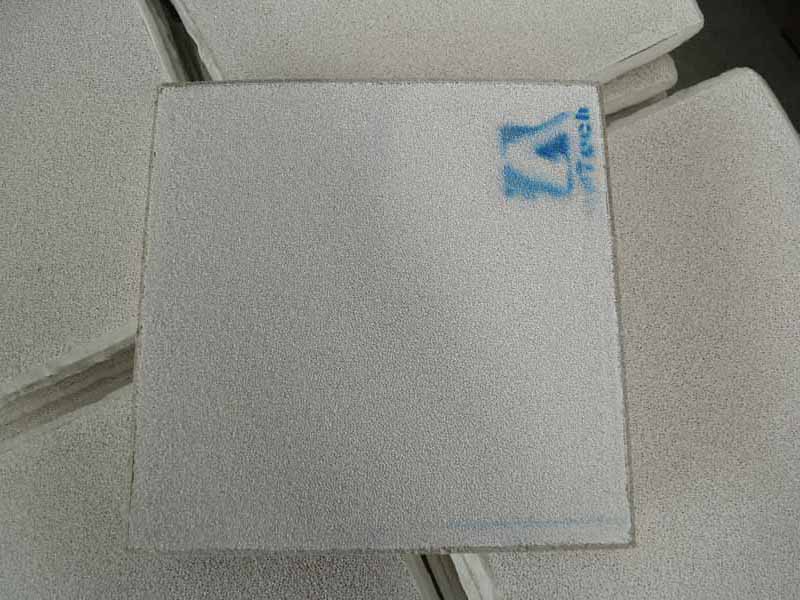

20 5月 Ceramic Foam Filter Rusal

Ceramic Foam Filter Rusal uses the formulas and processes of many well-known foreign companies. It has been carefully developed by introducing foreign production equipment and some raw materials.

Its performance fully meets or exceeds the level of similar foreign products.

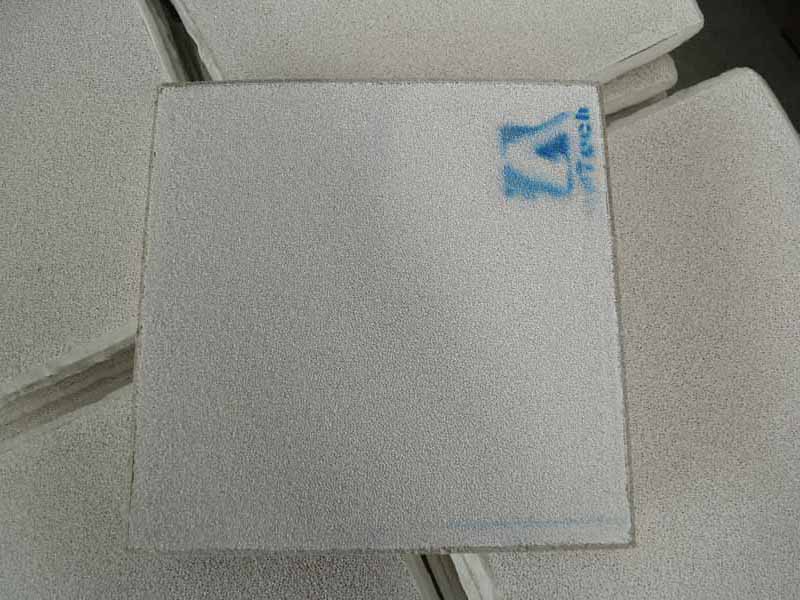

Ceramic Foam Filter Rusal product function

It can effectively eliminate large inclusions in the aluminum liquid.

It can remove tiny inclusions in the size of several microns in the aluminum melt that conventional processes cannot do.

Reduce the hydrogen content in the molten aluminum.

Through adsorption, the content of harmful elements (Na.k) in the aluminum liquid can be removed.

Note: Ceramic filter plates are disposable consumables when used in the aluminum processing industry. Users are requested to carefully consider their furnace capacity and select ceramic filter plates of corresponding specifications to avoid improper use or unnecessary waste.

Ceramic Foam Filter Rusal, applicable temperature 720 ℃, suitable for the filtration and purification of aluminum and alloy solutions.

In order to meet the increasing requirements for the quality of aluminum castings, the use of alumina foam ceramic filters (plates) is increasingly important. Filters are also widely used in ordinary sand casting such as tide casting and fixed part casting.

The filtration process is mainly based on the following considerations: on the one hand, the filtration makes the flow of aluminum liquid orderly and relatively calm, and on the other hand, the solid slag in the molten metal is effectively removed, and the casting alumina foam ceramic filter product effectively removes the molten metal Solid state inclusions, so aluminum alloys can be smoothly forged, aluminum foil manufactured, extruded, and other processes, resulting in a selection range of 10ppi coarse pore size to 40ppi extremely fine pore size, so there will always be a product standard that suits your requirements . Ordinary sizes and special sizes required by customers can meet the reference data of flux (20PPI) (square and round)

use the ceramic foam filter in the cff box

1. Clean the filter box.

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from bypassing.

3. Preheat the filter box and filter plate evenly to bring it close to the temperature of the molten aluminum.

4. Observe the changes of the aluminum hydraulic head during casting. The normal starting head is 75-150 mm. When the molten aluminum begins to pass, the indenter will fall below 25㎜, and then the indenter will gradually increase.

5. After filtering, remove the filter plate in time and clean the filter box.

Sorry, the comment form is closed at this time.