08 6月 Cff Filter

Cff Filter for smelting and casting of aluminum processing

Smelting furnaces are mostly used gas reverberatory furnaces or oil-burning reverberatory furnaces, with a general capacity of 20-40 tons or more.

The dao resistance heating reverberatory furnace is also adopted, and the capacity is generally about 10 tons.

In order to shorten the furnace loading time, improve the melting efficiency, reduce the absorption of gas and be involved in the oxide film, the industry has adopted a tilting top-loading round furnace.

It is best to use rapid analysis equipment to analyze the alloy composition during smelting and adjust it in time.

In order to ensure the purity of the melt, prevent the pollution of harmful gases and control the chemical composition, in addition to shorten the smelting time as much as possible, it should be covered with powdered flux mainly composed of potassium chloride and sodium chloride. The general dosage is 0.4~ 2%. The smelting temperature is usually controlled at 700~750℃.

The molten metal also needs to be refined and filtered to remove the harmful gas hydrogen and non-metallic inclusions in the metal to improve the purity of the metal.

Refining usually uses solid refining agent or gas refining agent.

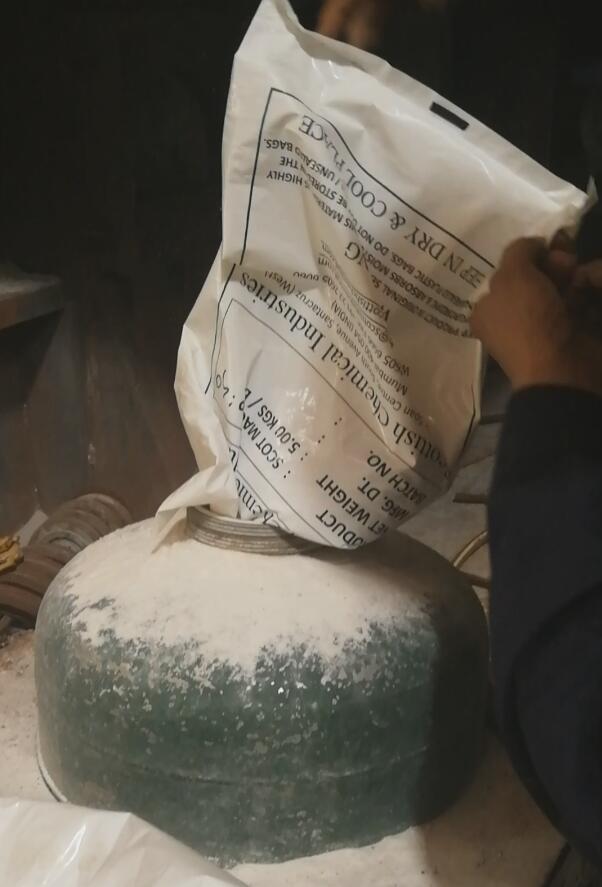

Solid Refining Flux is generally based on chloride salts, and is also used as a refining agent for hexachloroethane instead of chloride salts.

Early use of highly active chlorine gas as a gas refining agent, although the purification effect is good, but serious environmental pollution, so the development of nitrogen-chlorine mixed gas, inert gas and three gases (N2, Cl2, CO) refining agent, the effect is better.

In order to ensure the refining effect, the oxygen and moisture content in the refining gas should generally be less than 0.03% (volume) and 0.3 g/m3, respectively.

The dynamic vacuum degassing method also has good degassing and sodium removal effects.

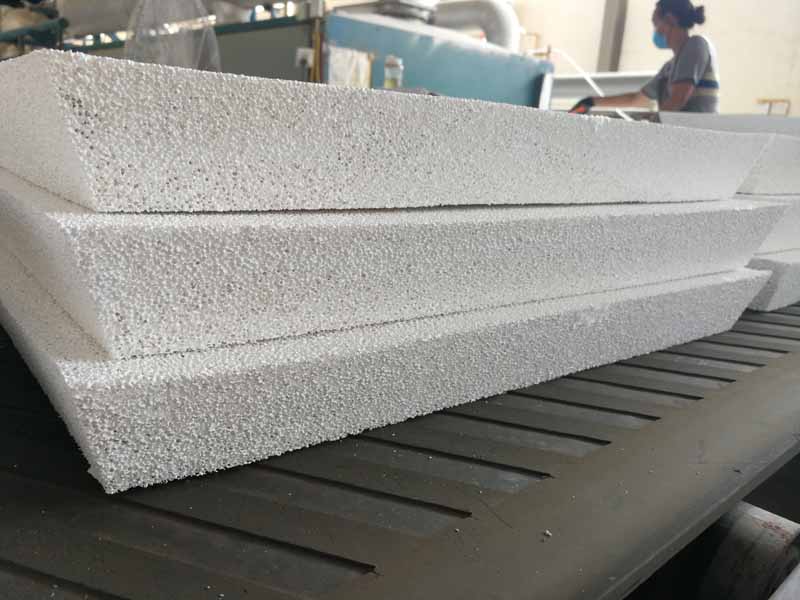

Cff Filter is a ceramic foam filter made of molten metal through neutral or active material to remove suspended inclusions in the melt.

As the stream of molten aluminum alloy travels through the tortuous path of the Cff Filter, non-metallic inclusions are captured inside the ceramic structure.

The filtered metal is significantly cleaner. Cleaner metal results in higher quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom line profit.

Ceramic Foam Filter structure are available in sizes from 7 inches to 26 inches square and a wide range of pore sizes from 20 ppi to 80 ppi.

Cff Filter includes preheat dots for temperature indication. SafeSeal® and other proprietary gasket formulations insure a secure fit in the filter bowl.

Casting generally adopts vertical or horizontal water-cooled semi-continuous casting method. In order to improve the structure and surface quality of billets in vertical casting, electromagnetic crystallization tank, short crystallization tank and hot top casting method (see metal solidification) have also been developed.

In the water-cooled semi-continuous casting method, liquid metal is introduced into a water-cooled crystallizer through a launder, and the liquid metal is cooled to form a solidified shell, which is pulled by the base of the casting machine or drops out of the crystallizer by its own weight to form a billet.

The process parameters vary greatly depending on the alloy composition and billet size. Generally, the casting speed and cooling speed should be increased as much as possible, and the height of the crystallization tank should be reduced.

The casting temperature is usually 50 to 110°C higher than the liquidus of the alloy. In addition, a continuous casting and rolling process for aluminum strip has been developed.

The production of plates and strips uses flat-roll rolling, and the basic processes are hot rolling, cold rolling, heat treatment and finishing.

For LY12, LC4 and other hard aluminum alloys with complex chemical composition, they should be homogenized before hot rolling. The treatment temperature is generally 10 to 15°C lower than the eutectic temperature of the low melting point phase in the alloy, and the temperature is kept for 12 to 24 hours.

The aluminum clad of the hard aluminum alloy is to place the aluminum clad plate on both sides of the billet after milling, and it is welded by means of hot rolling.

The thickness of the aluminum cladding layer is generally 4% of the thickness of the plate.

Hot rolling is generally performed above the recrystallization temperature.

Hot rolling can be performed on a single stand reversing rolling mill, or continuous rolling can be performed on multiple stands.

In order to improve the yield and production efficiency and develop large ingot rolling, the ingot weighs more than 10-15 tons.

Plants with an annual output of less than 100,000 tons generally use four-roller reversible hot rolling and a hot coiling process. The thickness of the hot rolled strip is about 6 to 8 mm.

For plants with a production of more than 100,000 tons, the single-stand or two-stand, three-stand and five-stand continuous rolling is used after the four-roller reversing hot rolling mill is opened. Hot finish rolling is carried out, and the strip thickness can reach 2.5 to 3.5 Mm.

The hot-rolled strip is used as a cold-rolled billet after it is rolled.

In order to ensure the best plasticity of the metal, it should be hot rolled in a single-phase structure.

The hot-rolling blanking temperature of LY11, LY12 and other alloys is 400~455℃.

The deformation rate of the first few passes is generally within 10%, and then gradually increases.

The pass deformation rate of pure aluminum and soft aluminum alloys can reach 50%, and that of hard aluminum alloys is about 40%. The total hot rolling deformation rate can reach more than 90%.

Sorry, the comment form is closed at this time.