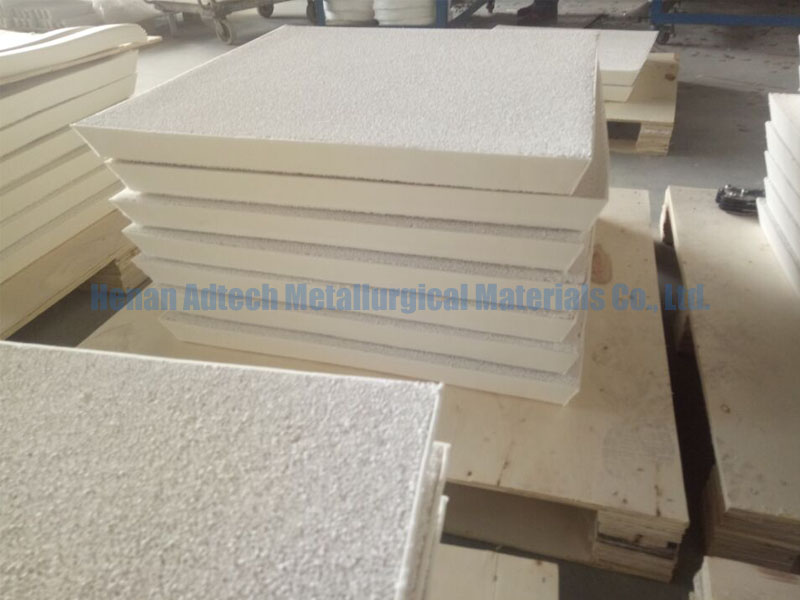

06 8月 China Ceramic Foam Filter Cff

China Ceramic Foam Filter Cff

AdTech China Ceramic Foam Filter Cff employs dedicated ceramic foam filter(s) to remove inclusions which are generated between the refining system and the mold table. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal. Accordingly, the quality and the productivity in downstream operations such as forging, extruding, and rolling are guaranteed.

At AdTech, the continual quest is to ensure that our customers receive the best technology available on the market to produce the highest quality billet, slab, or ingot for their customers. Our guarantee does not stop with our customer, but continues to our customer’s customer! Our technology guarantees conformance of casting quality for the most critical end-product applications.

Made from alumina, the China Ceramic Foam Filter Cff maintains its high strength and its excellent resistance to chemical wear through the cast.

Metals and metallic products have a special connotation with human civilization. It is considered to be one of the primitive material that human have mastered to use. However, all metals are not very stable in its rawest form. This form of metals may not have the optimum metallic properties and therefore it requires purification. Purification process of molten metal require ceramic ceramic foam filter, which ensure that all the impurities has been removed from the metallic solution. Once this process is achieve, metal is ready to be used in different types of applications through different processes.

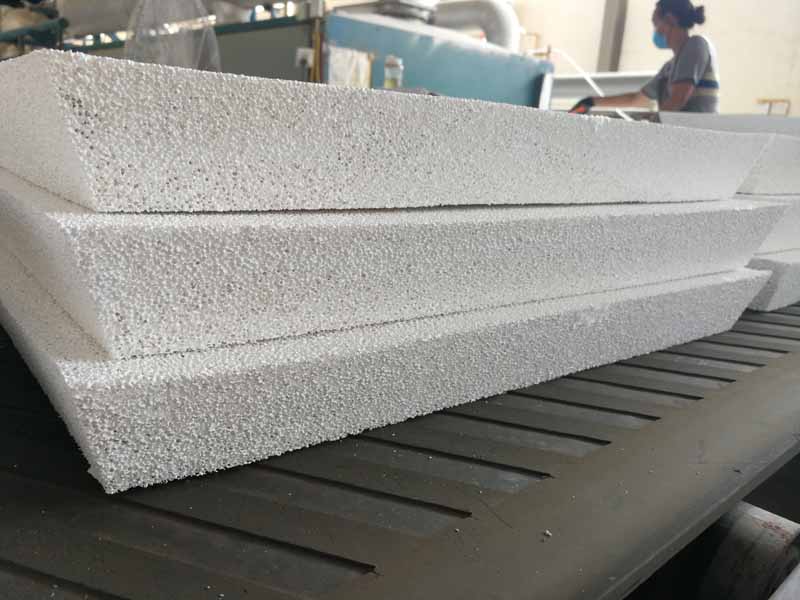

Compressed strength The amount of raw material used during the purification process is very high, as doing this process in small quantities is not a cost effective solution. Therefore, heavy amount of metallic solution is poured over these China Ceramic Foam Filter Cff and therefore it must have a high compressed strength to undergo the operation undamaged.

China Ceramic Foam Filter Cff

Natural melting points of various metallic elements are very high. The range of melting point of metals may vary but generally is around few hundred to more than thousand degrees Celsius. It is therefore very necessary that Asian Foundry Filters must have certain properties. Here are some useful properties Porosity It is the percentage of the pore space in the China Ceramic Foam Filter Cff. This property is very important in operations as a filter with much larger or smaller porosity can hamper the process. Therefore, it is recommended that porosity must be ideal in terms of the types of molten metal used.

No Comments