06 12月 Control of Molten Metal Flow

Control of Molten Metal Flow

The ways to gain better quality and higher casting performance is an urgent topic among aluminium producers today.

This issue is also often on the agenda at conferences like this and the subjects and technologies to achieve this varies.

Controlling the molten metal flow by maintaining predefined levels or level patterns is one powerful tool on the way to attain this.

Precimeter is specialized in applications for non-ferrous molten metal level measurement and molten metal flow control.

By integration of Precimeter products, any casting machine or process can have automatic level and flow control.

By retrofitting, any existing casting line with traditional technology can easily be upgraded with Precimeter technology and improve casting performance in a cost efficient way. This paper will focus on the main benefits from automatic level control and how some plants have achieved improvements in their casting process of DC (Direct Chill) slab (or rolling ingot) casting after implementing Precimeter technology.

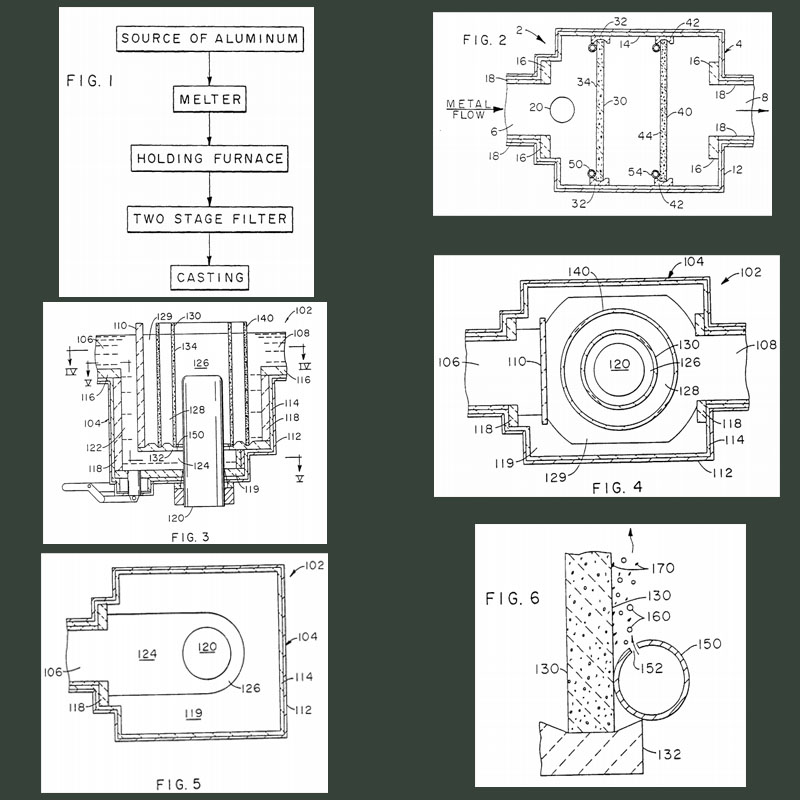

1.Control of Molten Metal Flow Introduction

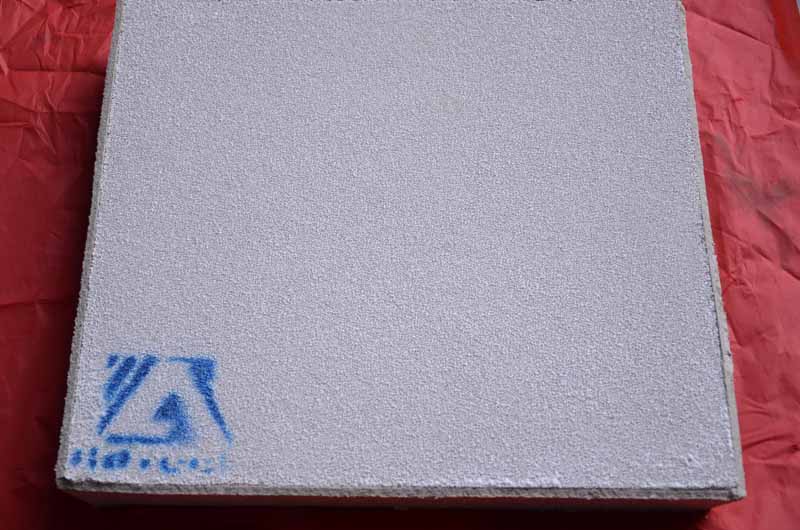

When casting slabs there are a lot of different factors and parameters that affect the quality of the product. The cooling system, water flow and temperature, degassing, filtering, melting temperatures, grain refining, casting speeds etc. are all important factors and without any direct relation to metal level control.

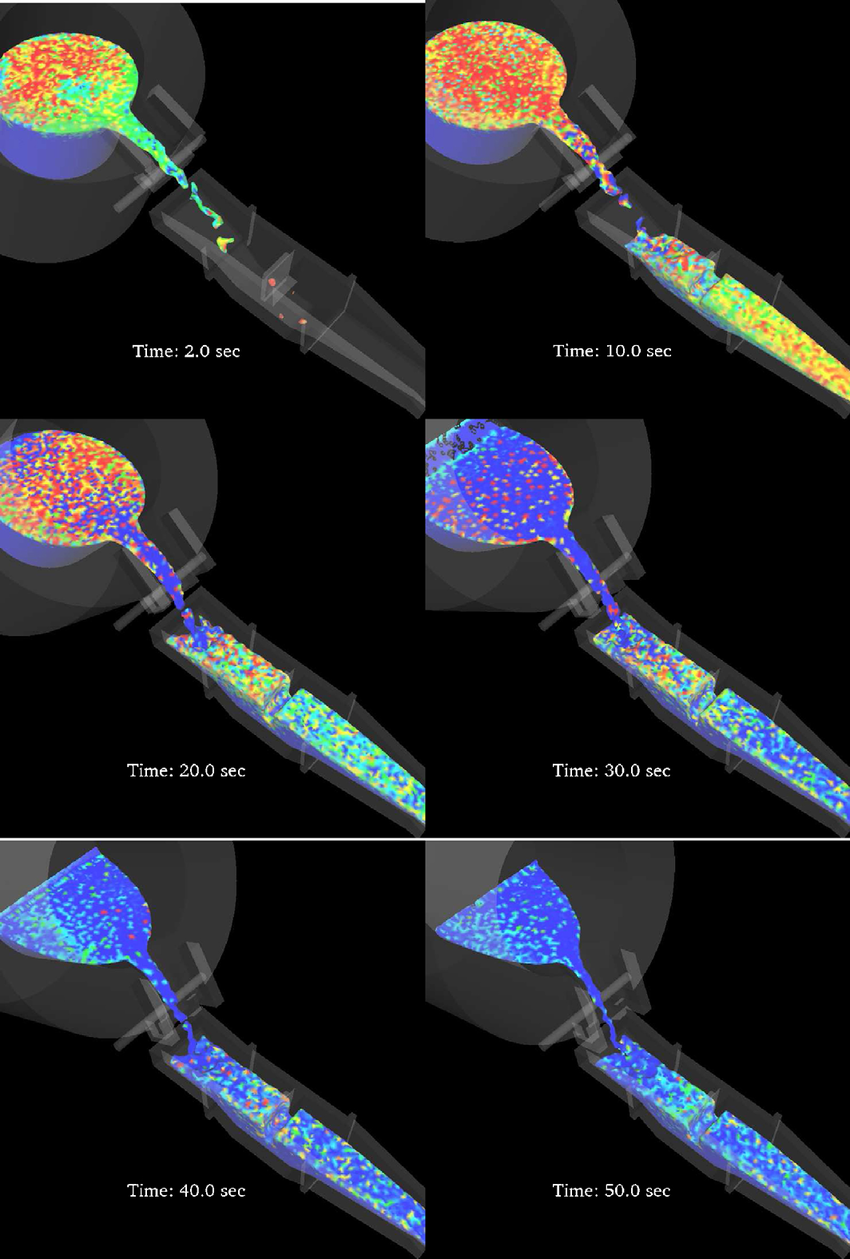

However, when we look at, metal distribution, metal transfer, fill rates, cooling optimization and metal solidification, metal level control is a powerful tool that is needed to reduce the shell zone, prevent butt curls and cracks and to improve the surface structure.

Control of Molten Metal Flow will also enable repetitiveness and traceability through recipes. By accurately controlling the metal level the plant will gain productivity through higher recovery, shorter cycles and less down time. On top of this, maybe the most important thing of all, operator safety will be highly increased due to atomized start and shutdown operations.

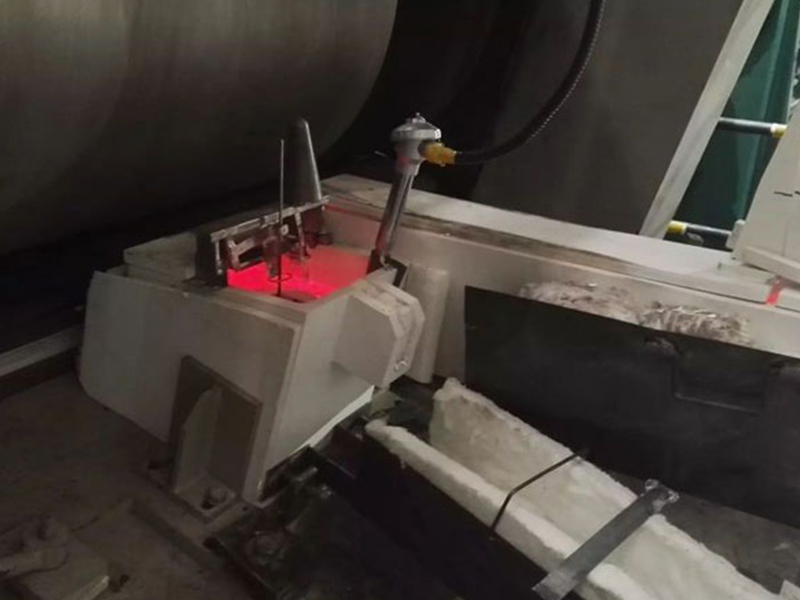

2. Metal Level and Flow control equipment for DC slab casting

A typical fully automatic casting system can consist of ProH metal level sensors, starter dams, pin positioners and a furnace control system (such as a tap out actuator or a tilting furnace control system). This equipment is easily installed on the existing launder system by local resources or using the flexible Precimeter mounting rig suitable for any launder type and size.

3.Control of Molten Metal Flow Sensors

The Precimeter digital camera laser sensor has been developed exclusively to measure on molten metal surfaces. The Precimeter ProH series is specifically designed for high performance in different aluminium (and other non ferrous metals) applications. Measuring stability and accuracy (typically 0.1mm) with any alloy makes it one of the best performing sensors for mould level control available on the market today. The Precimeter ProH sensors are being used world wide by most major aluminium producers and are also integrated by many casting equipment manufacturers in their

casting lines and machines.

No Comments