14 9月 Conveying Molten Aluminum Aluminum Silicate Launder

Conveying Molten Aluminum Aluminum Silicate Launder

Applications of investment casting have actually grown significantly during modern times. Investment castings are made use of to create parts in aerospace, transport, material handling, pump as well as valve, food handling as well as even more. Sculptures as well as initial art also use investment spreading to create a metal version of an artist development. Financial investment casting with a high quality aluminum silicate launder for conveying molten aluminum is likewise made use of to create clinical implements as well as components made use of inside the body.

Improvements in the pattern production, wax, refractories, as well as melting equipment have actually caused procedures that can hold incredibly tight dimensional homes. Modern financial investment castings normally hold measurements that are gauged by a few thousandths of an inch per inch. This permits parts to be made that commonly could be made use of straight from the manufacturer without succeeding machining. Worst cases permit the components to be near web shape, which decreases the quantity of taking care of as well as refining to be finished on the spreading. Users of these casting procedures can likewise release the process to produce parts that could be gathered thousands of various materials including steel, non-ferrous materials, duplex alloys, aluminum, iron, and more.

The background of financial investment spreading with a high quality aluminum silicate launder for conveying molten aluminum offered by www.adtechamm.com will continually be redefined with the innovation of products used while doing so. Each passing away year has actually revealed that basic materials could be combined in such a fashion that results in renovations of process as well as expense. Financial investment cast wax, ceramic, as well as alloys integrated with better devices to generate spreadings on a high or reduced volume basis make certain that the process will be deployed well into the future.

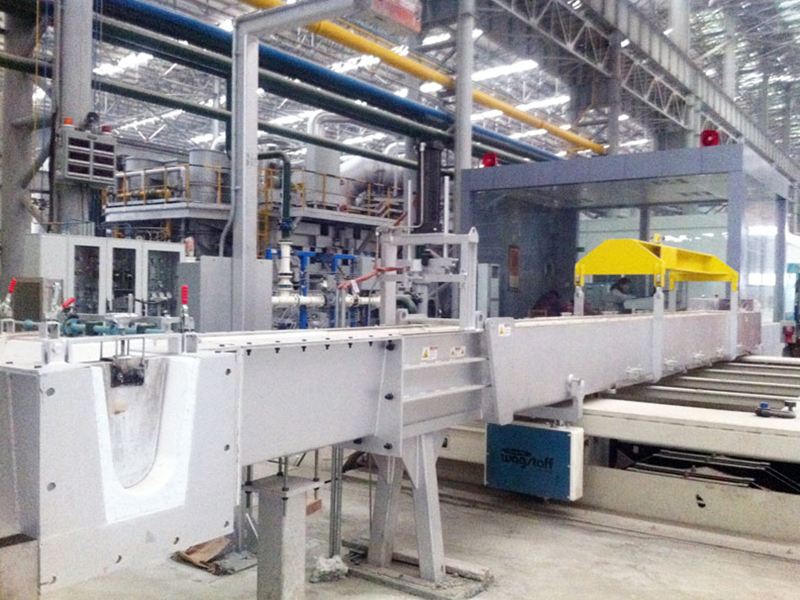

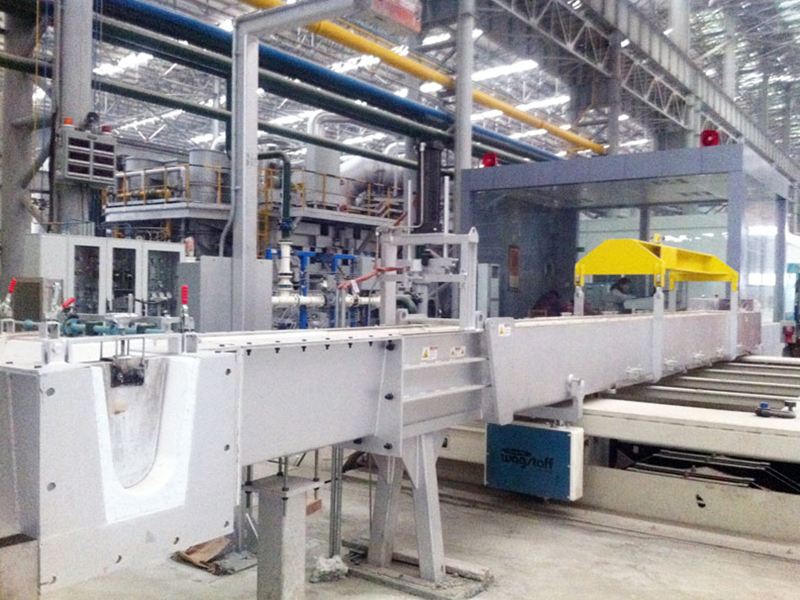

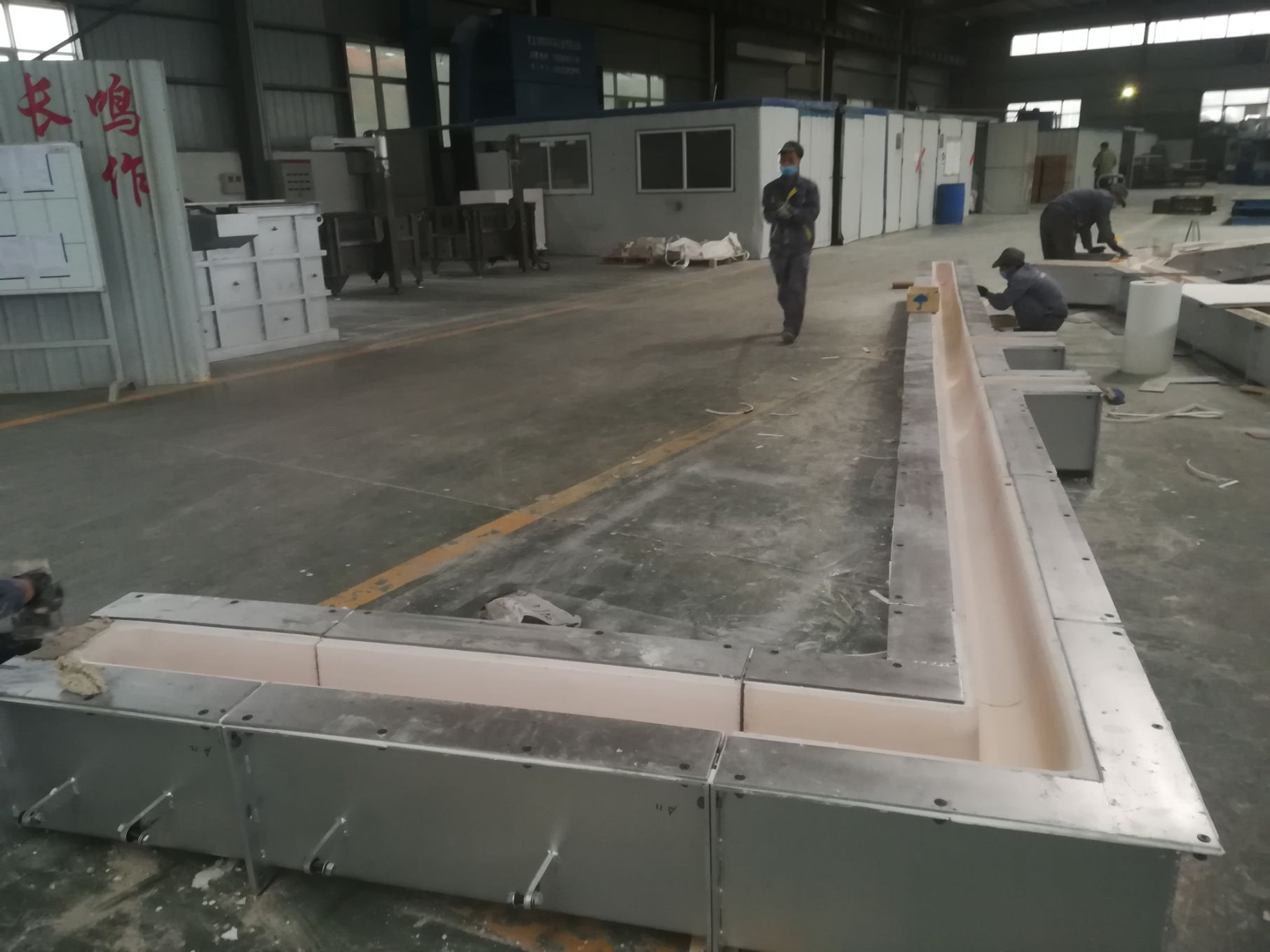

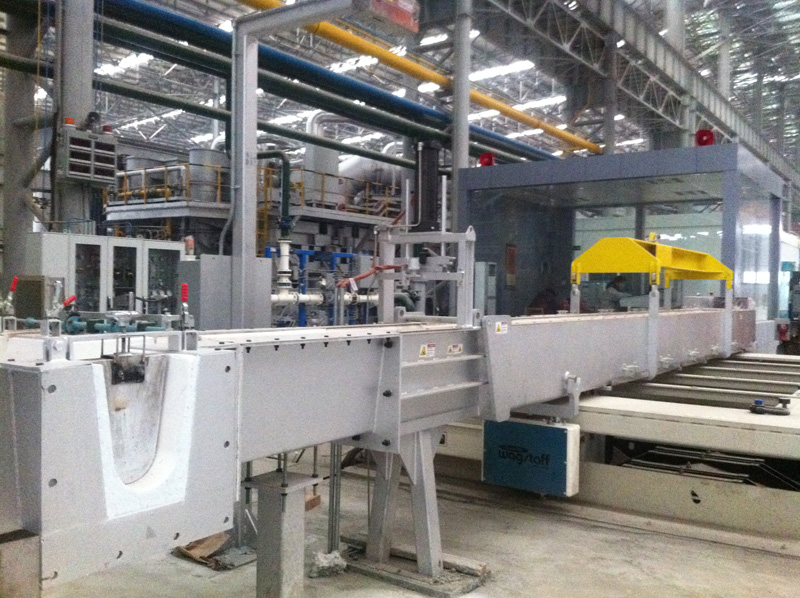

Aluminum Launder from AdTech is the integrated launder unit manufacturer which is specialized in the development of new material and production of high-performance insulation sealing. Since 2012, our company has started to R&D overall launder, degassing unit and plate filtration unit. Supply integration services in high-precision aluminum alloy casting. Got good reputation in market.

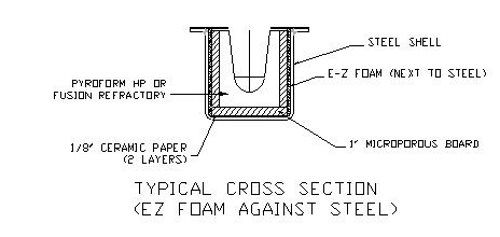

The integrated launder unit has the long lifetime lining. Use new high-silicon melting material which is corrosion resistance, non-stick molten aluminum, non-polluting to molten aluminum. Can meet the high value-added, high-tech performance aluminum casting requirement.

The integrated launder unit is installed between the furnace and the casting machine and it has dual function: transportation and insulation. Mainly used in the transportation of molten aluminum between furnace, purifying furnace, casting platform, degassing unit and filtrating unit for the aluminum precision casting. It is suitable for casting such aluminum materials as below stated: computer hard drive, micron-grade aluminum foil, PS board, canning materials, fan blades of jet turbine engine, etc.

No Comments