25 8月 Daiki Aluminum Ceramic Foam Filter

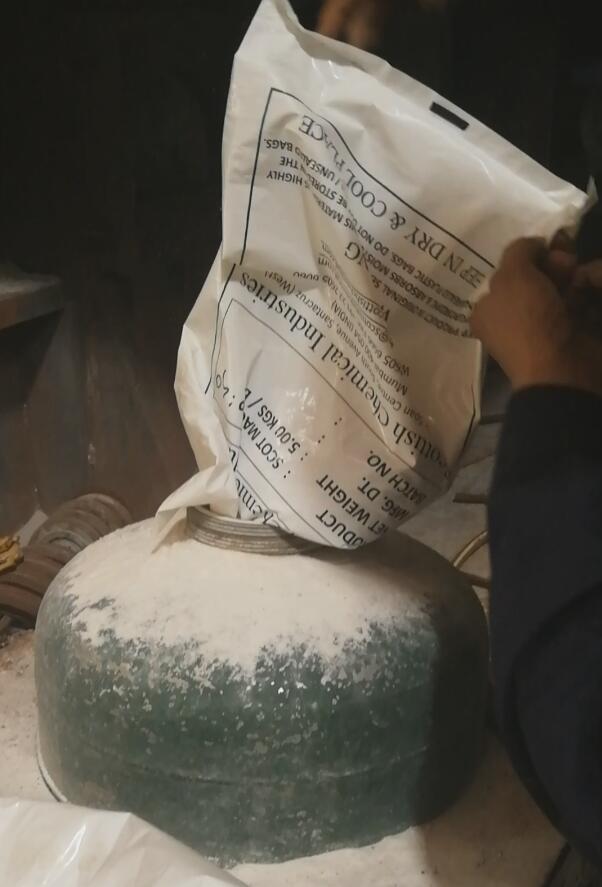

Daiki Aluminum Ceramic Foam Filter is used to filter molten aluminum. Its ceramic material has a high melting point and will not melt or decompose into molten metal during the casting process.

Foundry Ceramic Filters uses a three-dimensional network structure and organic foam with connected pores as a carrier to invade the thixotropic alumina material slurry.

The square-corrected center-distance automatic extrusion process is adopted to make the slurry evenly distributed on the carrier foam skeleton, and it is baked and cured at a high temperature of 1180°C.

Installed in the filter box, used to filter impurities in the aluminum alloy liquid to meet the production of aluminum alloy precision castings with high added value and high technical performance such as aviation and transportation.

Such as computer hard disk, PS board base for printing, canned food, jet turbine fan blades, and other products.

Daiki Aluminum is introducing the sales@adtechamm.com mailbox of the foundry ceramic filter factory to aluminum melting and foundries in Japan and Southeast Asia.

The use and selection of Daiki Aluminum Ceramic Foam Filter The ceramic foam filter plate are installed in the filter box between the furnace mouth and the distribution plate.

The filter box can withstand multiple chills and impacts without cracking and has the advantages of high strength and good insulation performance. It is currently the best material for making filter boxes and runners.

The closer the filter box is to the manifold, the better because this can shorten the flow distance of the molten aluminum after filtration, and reduce or avoid the re-generation of oxides.

Adtech continues to promote its aluminum metallurgical purification products, and at the same time recruits competent agents.

1. Go out to participate in trade fairs

Large-scale trade fairs in Germany, Russia, India, Malaysia, and other countries

Actively participate in product exhibitions jointly produced with the company’s products to enhance its own brand effect.

Promote ceramic filters, online degassing equipment, online filtering equipment, refining agents, plugs, and other products used in the aluminum casting industry. Find a suitable foreign agent, investigate and analyze the target agent in advance to achieve pertinence.

2. The agent should have a customer base

Agents should have a relatively good customer base in a certain aluminum casting industry.

There are certain distribution agencies and personnel, or there are successful cases of acting for other products, such as ceramic filters, plugs, online degassing equipment, etc.

It is the best choice to represent distributors who have greater influence in the region.

3. Good agency reputation

A good business reputation is a basis for long-term successful cooperation between the two parties in economic activities.

Reputable agents will not cause economic disputes, and will not affect the cooperation between the two parties because of interest issues.

4. Strong agent ability

The agent you are looking for must have strong marketing capabilities in the aluminum casting industry.

Only with keen market insight, mastering certain distribution channels, cooperating with him, and using his ability to combine with his own products, can it be possible to effectively open up foreign markets.

5. Acknowledge the sales philosophy of the agent

Mutual understanding and trust between partners is the perfect start to cooperation.

The sales philosophy and business philosophy of the agent should have something in common. Both parties can agree with each other’s ideas and practices in economic activities, and promote the smooth development of various agency work.

No Comments