13 May Damage mechanism of refractory materials for aluminum alloys

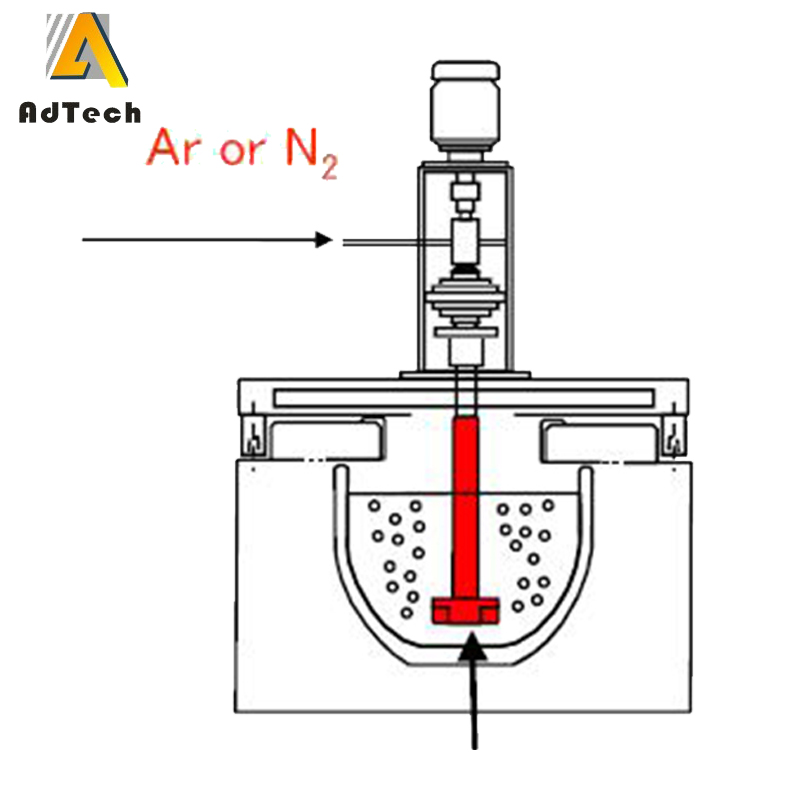

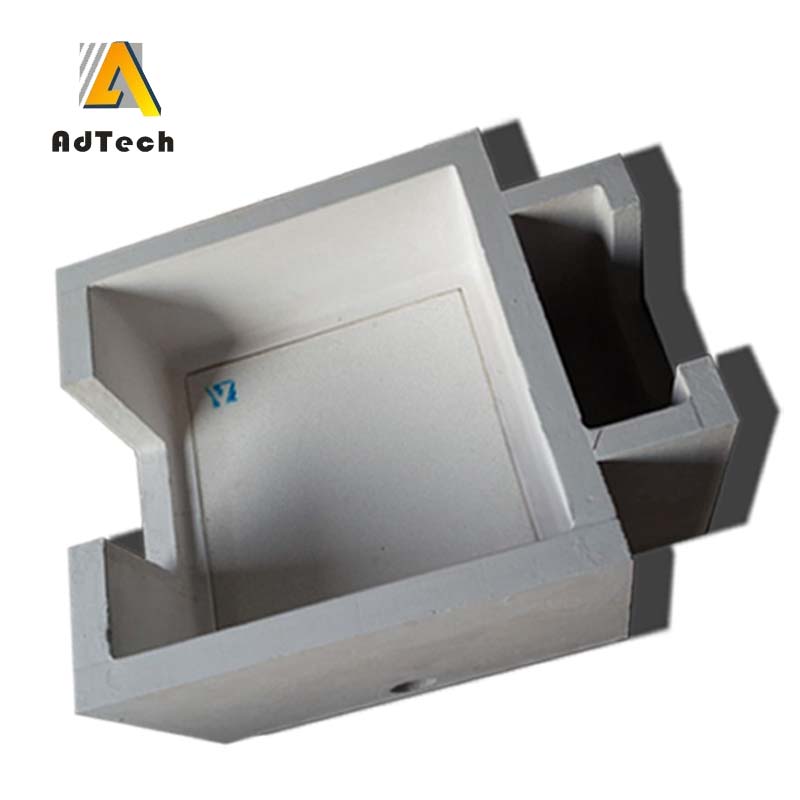

The melting point of aluminum is 660°C, and the temperature of the aluminum liquid is 700~800°C. The viscosity of the pure aluminum melt at 750°C is 0.104Pa·s, which is very close to the viscosity of water at 20°C, 0.1Pa·s, and has extremely strong Permeability. At high temperatures, it easily reacts with the refractory lining. It is accompanied by volume changes, causing the structure of the refractory material to change, changing the chemical and physical properties of the material, and causing damage to the refractory material. Wetting of molten aluminum and refractory materials is a prerequisite for chemical reaction. Therefore, the unique performance requirements for refractory materials for aluminum alloys include resistance to erosion and permeability of liquid aluminum, and non-wetting with liquid aluminum.

The intermittent operation mode of aluminum alloy smelting and purification determines the following ways of damaging refractory materials:

1. Surface chemical reaction: Surface chemical reaction is often accompanied by volume changes, which can cause structural damage, peeling, and erosion of refractory materials, causing the lining layer to become thinner gradually

4Al+3SiO2 =2Al2O3 +3Si ΔV=-35% (1.1)

2Al+Fe2O3 =Al2O3 +2Fe (1.2)

SiO2 +2Mg=2MgO+Si ΔV=-57% (1.3)

2SiO2 +Mg+2Al=MgAl2O 4 +2Si ΔV=-25% (1.4)

3(3Al 2O3·2SiO2)+4Al=12Al2O3 +6Si ΔV=-18% (1.5)

3TiO2 +4Al=2Al2O3 +3Ti ΔV=+11% (1.6)

3Mg+4Al2O3 =3MgAl2O4 +2Al ΔV=+17% (1.7)

3Mg+Al 2O3 =3MgO+2Al (1.8)

2. Deep chemical reaction

Alloying elements such as Mg (boiling point 1107°C) and other high vapor pressure elements easily penetrate deep into the material along the pores of the refractory material, and undergo the following reactions, causing the refractory material to expand and become loose, causing cracks and further accelerating the degradation of the refractory material by the aluminum alloy melt. Penetration and erosion. 2Mg(g)+O2 =2MgO, 3Mg(g)+Al2O3 =3MgO+2Al

3. Physical penetration

The working method is mostly intermittent. After the low-viscosity aluminum alloy melt penetrates the pores of the refractory material, the refractory material will continue to expand and contract as the lining material encounters rapid cooling and rapid heating during heating, insulation, cooling, and other cycles, which will eventually cause the refractory material to peel off.

4. Mechanical damage

Al2O3 is easily generated at the gas-liquid-solid three-phase interface formed by air, aluminum alloy melt, and refractory materials, forming corundum nodules. The corundum tumor is closely combined with the furnace lining. When it is removed by mechanical, flux, or manual methods, it will cause a certain degree of damage to the furnace lining structure.

No Comments