16 10月 Degasser Equipment

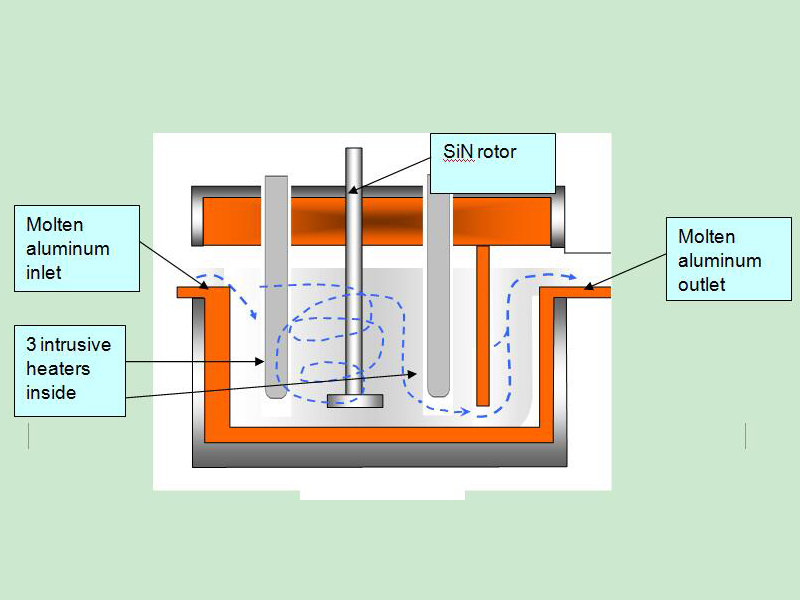

Degasser Equipment rotates the ejector immersed in the melt, so that the scavenging gas (usually an inert gas) is distributed in the melt as small bubbles for the purification of aluminum melt and hydrogen degassing.

The smaller and more frequent the removal of bubbles, the better the melt can be degassed and there is no oxide impurities.

Degasser Equipment can not only be used in the degassing process, but also can remove the oxides remaining on the surface through the baffle (knife) when operating correctly.

Rotary degassing is usually combined with an inert gas suitable for the affected melt, such as nitrogen.

In some cases, the inert purge gas will also be mixed with low concentrations (<2.5%) of sulfur hexafluoride or chlorine.

In the aluminum melt, due to the fine distribution of the rotor purge gas, the hydrogen content is greatly reduced much faster than other purge gas methods.

With this principle-almost any bath surface can be washed-a very wide bubble distribution is achieved in the entire processing container, and the processing time can be shortened through effective degassing and melt purification.

Sorry, the comment form is closed at this time.