01 3月 Degassing And Purification Treatment Equipment

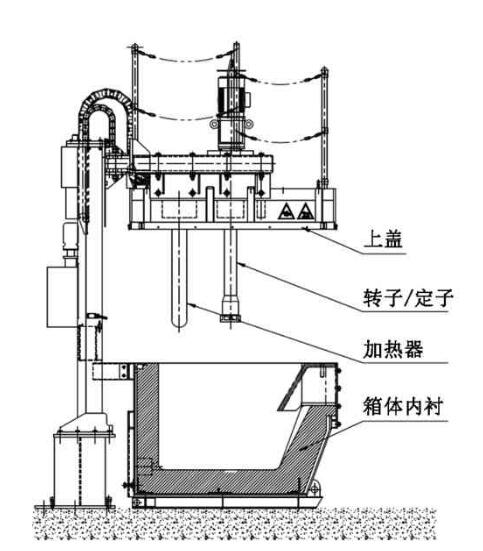

Degassing And Purification Treatment Equipment is installed between the furnace and the casting machine to remove hydrogen and other residues contained in the molten aluminum and its alloys that affect its quality and mechanical properties.

It has a dual function: processing and heating. It is mainly used for the purification of the melt in the production of high-precision aluminum products.

The degassing device is used for dust removal, smoke removal, and degassing device in the smelting industry of foundry aluminum plants, and the purification and desulfurization effect can reach more than 90%, and the recovery rate is high.

The degassing device of the aluminum plant has an ultra-long life furnace body using a new type of high-silicon molten material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride (Si3N4) ceramic manufacturing technology and The production technology of aluminum products with high added value and high technical performance requirements.

The main advantages of Degassing And Purification Treatment Equipment

1. The rotor is easy to locate and replace.

2. The control panel is easy to use and can be automatically/manually controlled. When the set degassing time is completed, the rotor stops, the air supply is automatically closed, the cantilever automatically rises, and the indicator flashes, it will automatically stop to remind the operator.

3. Nitrogen or argon can be used, which greatly reduces the degassing time and reduces the cost of refining, without any pollution to the environment, and the working environment is greatly improved.

4. The flow of inert gas is controllable and can be set, which greatly improves product quality.

The rotor speed can be adjusted, and the speed can be equipped with a frequency conversion speed control electronic digital display, which brings convenience to the operator.

5. High degassing efficiency, which can greatly reduce the waste caused by bubbles and inclusions, and greatly increase the yield.

6. The equipment is equipped with an online temperature measuring device for molten aluminum, which can know the temperature rise and fall of molten aluminum at any time during degassing, which is convenient for casting.

7. There is no corrosion to the lining of the ladle or crucible boiler.

8. Due to the effect of the baffle, the surface of the molten aluminum is stable, reducing secondary pollution during the processing.

9. Humanized design, sturdy structure and simple maintenance.

Degassing And Purification Treatment Equipment working video

No Comments