21 3月 Degassing With Nitrogen

Degassing With Nitrogen

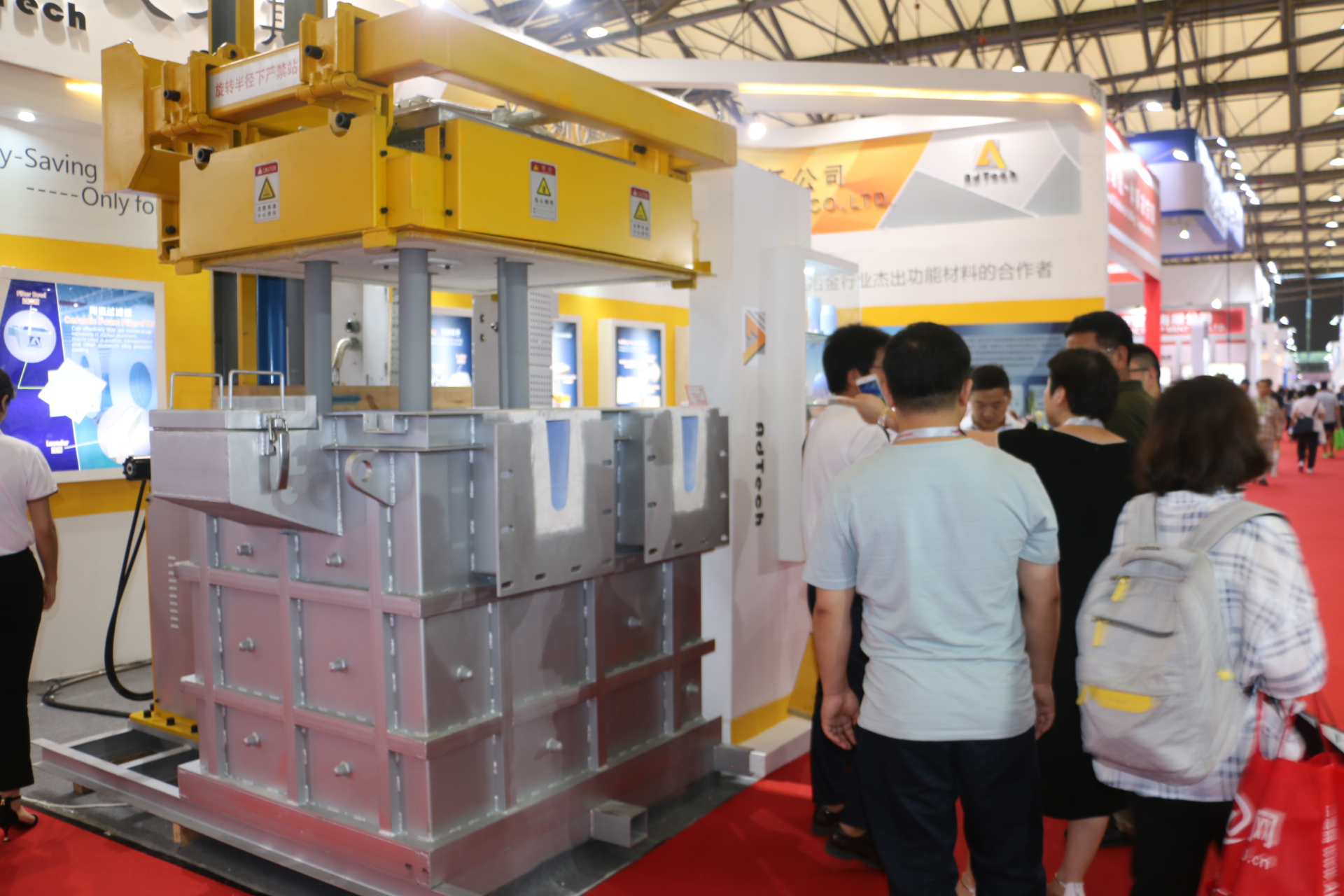

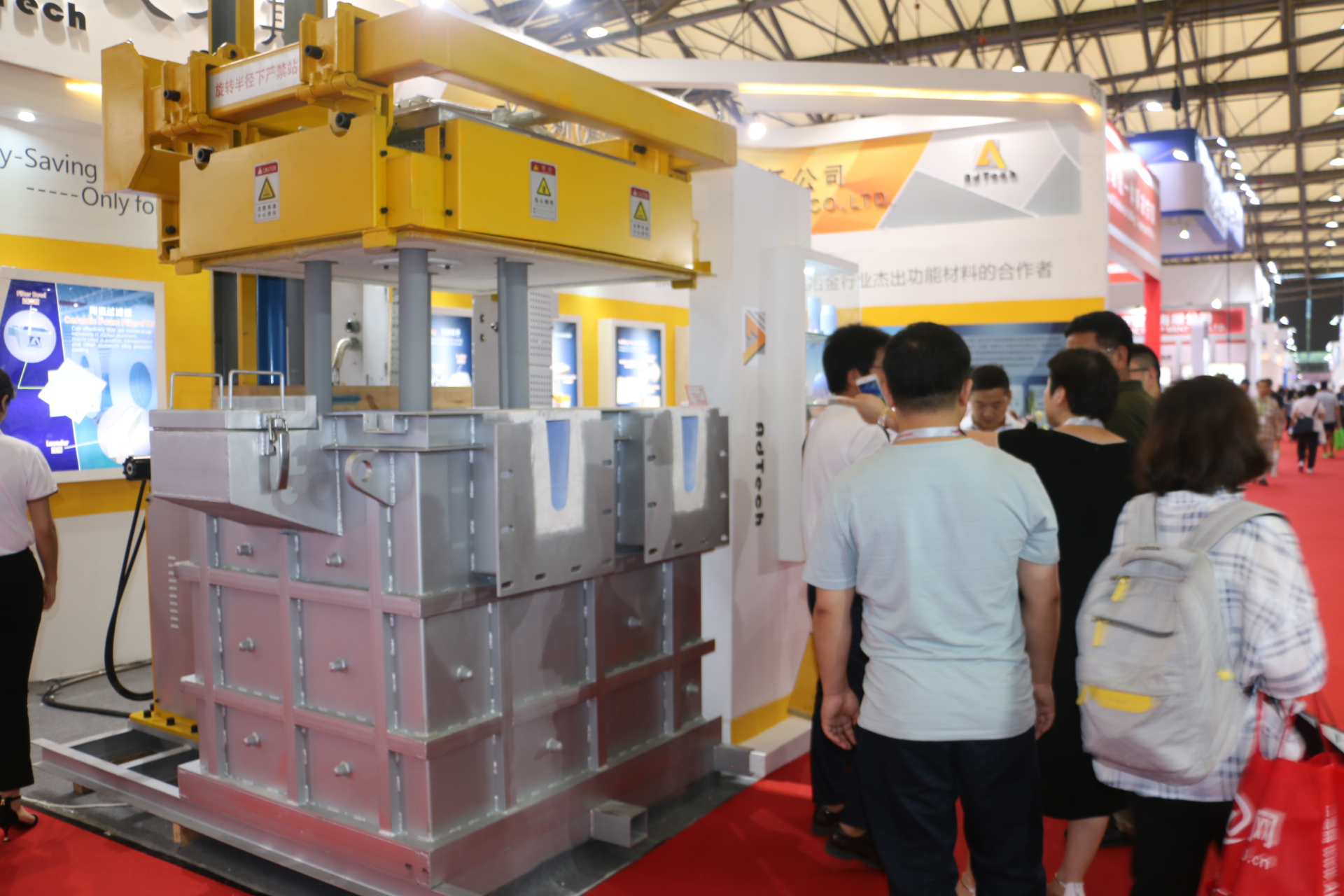

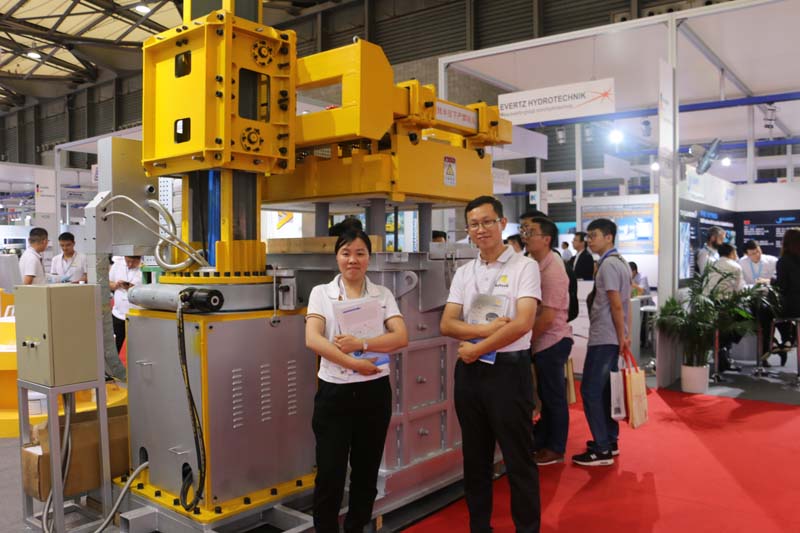

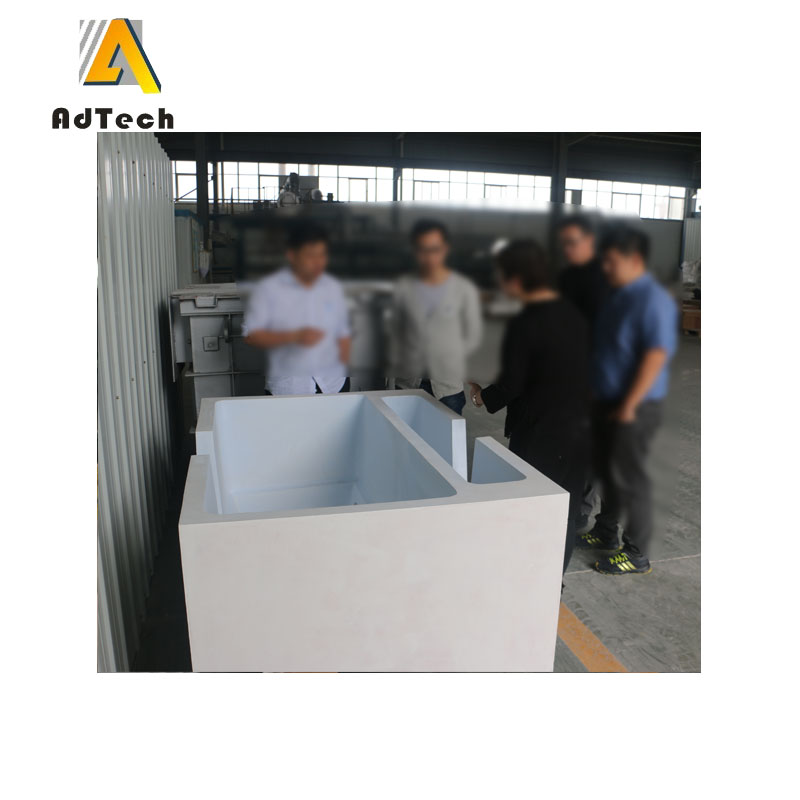

AdTech Degassing With Nitrogen is installed between the furnace and the casting machine to remove hydrogen and other residues from the molten aluminum and its alloys that affect its quality and mechanical properties.

Features of Degassing With Nitrogen

1. The two rotors rotate in the opposite direction, which can stir the metal melt more strongly and evenly, improve the stronger degassing efficiency, and provide timely degassing for more aluminum liquid;

2, the equipment installation and positioning is simple, in addition to replacing the loss parts after the placement, basically do not need to move again!

3, the two rotors can independently control the speed, gas flow size, etc.;

4, simple control, using button operation, degassing time can be set (0.01 seconds ~ 999 hours adjustable or unlimited), there is automatic / manual control mode, generally automatic control when online use;

5. When the set degassing time is completed, the rotor will automatically stop, the air supply will be automatically turned off, the indicator flashes to alert the operator, and the safety is high; when it is used as the online degassing, it can continuously operate continuously;

6. Using nitrogen or argon as the degassing medium, the advanced degassing principle greatly reduces the degassing time, improves the efficiency, reduces the refining cost, has no pollution to the environment, and greatly improves the working environment;

7. The inert gas flow can be controlled, and the optimal setting can be made, which can greatly reduce the waste products caused by bubbles and inclusions, greatly improve the yield and improve the mechanical properties of the castings;

8. Provide stable and repeatable degassing effect, which can achieve efficient production for customers without affecting the production process.

9. There is no corrosion to the ladle or the boiler lining;

10. The equipment main shaft and motor are equipped with air cooling device, which can effectively reduce the working temperature of the main shaft and motor and prolong the service life;

11. The bottom of the equipment is equipped with an insulation layer with excellent thermal insulation performance, which can prevent the deformation of the equipment caused by the excessive temperature of the aluminum liquid;

12. With emergency shutdown button, the switch is simple and safe, the structure is firm, the maintenance is simple, and the maintenance requirements are low.

The principle of Degassing With Nitrogen

Degassing With Nitrogen is stirred by a controlled rotating graphite shaft and a rotor, and the metered inert gas is pressed into the aluminum liquid through the rotor and dispersed into fine bubbles, which are uniformly dispersed in the liquid metal, and the gas partial pressure of the bubbles is zero.

Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, and inertness of useless hydrogen and some non-metallic inclusions adheres. The gas bubbles float up to the surface.

When there is a special degassing filter box, these impurities are isolated before the pouring, and then the desulfurization and deoxidation inclusions are achieved by the slag, and the degassing principle is also recognized, and the efficiency is high.

It does not affect the production process, can improve the purity of aluminum liquid in a short period of time, reduce the scrap rate, improve production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products.

No Comments