19 11月 Dual-Rotor Online Degasser

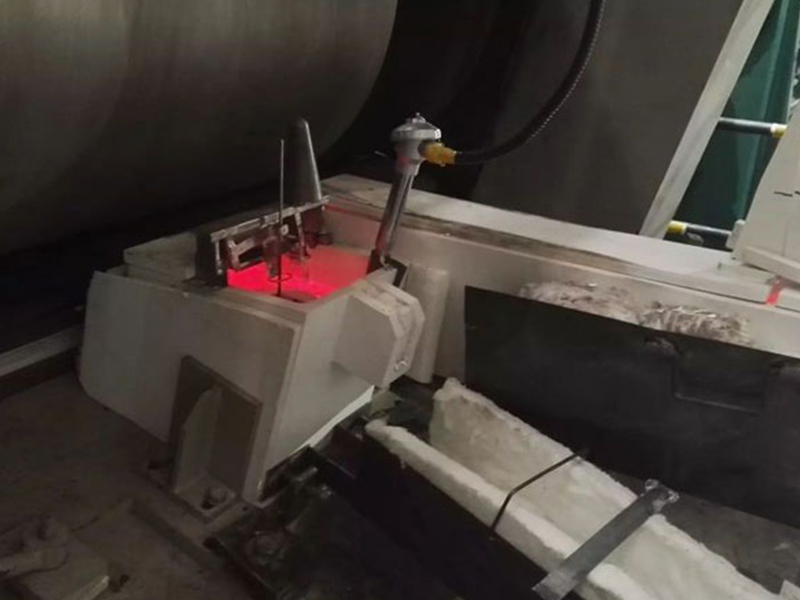

Dual-Rotor Online Degasser

Dual-Rotor Online Degasser has been recognized by the majority of customers.

Dual-Rotor Online Degasser is specially designed for online degassing of aluminum liquid with high flow rate, high gas content and high inclusion. It has three independently controlled Dual-Rotor, which can provide more powerful continuous degassing capacity.

Dual-Rotor Online Degasser is directly connected to the flow channel and can be lifted and rotated by a certain angle to facilitate the replacement of the loss parts. The good heat insulation design can provide 24-hour online uninterrupted degassing; the device is equipped with a gas underpressure alarm function. The inert gas can automatically alarm when the source pressure drops to a limited pressure. The warning light prompts the operator to change the gas source in time to avoid the occurrence of unqualified aluminum liquid due to lack of gas.

Since the device has dual rotors, when the device is used as an online degassing device, please prepare the spare air source in advance to facilitate timely replacement during undervoltage.

The degassing principle of the Dual-Rotor Online Degasser

Stirring the aluminum liquid through the controlled rotating graphite shaft and the rotor, and simultaneously injecting the metered inert gas into the aluminum liquid through the rotor and breaking it into fine bubbles to uniformly disperse it in the liquid. In the molten metal, the gas partial pressure of the bubble is zero. Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubble, and some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, which is useless. Hydrogen gas and some non-metallic inclusions adhere to the inert gas bubbles floating up to the surface.

When there is a special degassing filter box, these impurities are isolated before the pouring, and then the desulfurization and deoxidation inclusions are achieved by the slag. The degassing principle is also recognized, the efficiency is high, and the production is not affected. The process can improve the purity of aluminum liquid in a short period of time, reduce the scrap rate, improve production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products, which cannot be achieved by traditional degassing methods.

Description of the performance of Dual-Rotor Online Degasser

1. The Dual-Rotor Online Degasser can realize continuous degassing of the aluminum melt, improve product quality and not affect the production process. The device consists of a box, a cover, a heating system, a pore system and refining. The system consists of the ability to remove hydrogen, alkali metals and other impurities from the aluminum melt.

2. The Dual-Rotor Online Degasser, the heater protection sleeve and the thermocouple material are all silicon nitride materials independently developed by Ivans. With the unique internal mixing spoiler design, it can ensure a good stable degassing effect. According to the different processing capacity, the equipment can be divided into single-chamber single rotor, double-chamber double rotor (2B2R) and three-chamber three-rotor.

3. The Dual-Rotor Online Degasser mainly processes molten aluminum liquid containing a certain amount of hydrogen and other residues (alkali metal, slag inclusion), and is removed after being treated by degassing equipment. The treatment principle is gas flotation principle, process gas (inert gas) Or a mixture of inert gas and chlorine gas is injected into the melt through the rotor and broken into uniform dispersed microbubbles by the rotor, and the microbubbles rise to the surface of the melt, and the following work is completed during the ascending of the microbubbles: hydrogen is adsorbed into the bubbles It is excluded; the alkali metal is eliminated by chemical reaction with chlorine (formation of chloride); the inclusions are trapped by the bubbles and then rise to the surface of the melt to form dross.

No Comments