17 1月 Feed Caster Nozzle

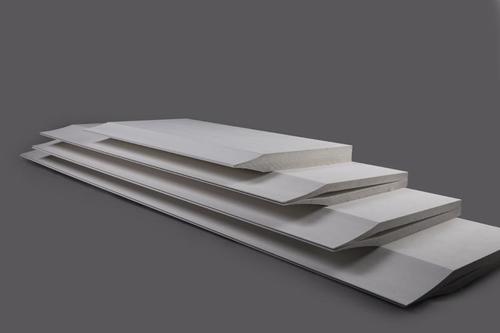

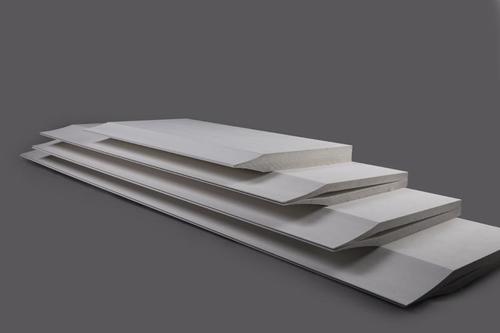

Feed Caster Nozzle plays a role of supply and distribution in the casting and rolling production, and provides a uniform flow field and temperature field for the casting and rolling.

The aluminum casting rolling mill includes two rolls, an upper roll and a lower roll. The non-stick aluminum casting nozzle is set in the gap between the upper and lower rolls. The Feed Caster Nozzle includes two casting nozzles, which are The upper nozzle piece adjacent to the roller and the lower nozzle piece adjacent to the lower roller. As the production time continues, some carbon deposits and fine particles may accumulate on the upper and lower nozzle pieces These slags will eventually form dark lines and scratches on the surface of the aluminum plate, which will seriously affect the quality of the aluminum plate. These defects are difficult to eliminate by conventional means. In order to overcome these shortcomings, the traditional method is to re-rise the board, that is, remove the slag after the production is stopped and then re-produce. However, the re-raising will greatly affect the production efficiency and significantly increase the production cost.

Preparation work before using Feed Caster Nozzle

A. Adjust the temperature of the molten aluminum in the standing furnace to 750℃±10℃ (the upper limit is taken in winter and the lower limit is taken in summer).

B. Check whether the runner system is tightly integrated, and put various vertical plate tools in the right position.

C. Adjust the graphite spraying limit according to the board width, and assemble the front box thermocouple.

D. Start the machine train to check whether the system of each part of the equipment is normal (cooling water).

Feeder Casting Tip position adjustment

A. Hoist the grilled casting nozzle assembly to the casting and rolling mill, and align the position on the casting nozzle platform.

B. Adjust the horizontal position of the Casting Tip to an appropriate value

C. Slowly move the casting nozzle to the roll gap, adjust the vertical and horizontal positions to reach the predetermined length of the casting zone, and observe the best state of the gap between the casting nozzle and the upper and lower rolls.

Molten aluminum discharge

A. After the preparation of the i board is completed, the operators enter each position according to the division of labor.

B. Open the flow hole of the holding furnace, H aluminum liquid preheats the launder and the front box, and the preheated H aluminum liquid flows into the slag box through the discharge groove.

C. Stir the spout box and filter box when the current box temperature is 700℃, and clean the slag deposited on the bottom.

Sorry, the comment form is closed at this time.