27 11月 Feed Tip

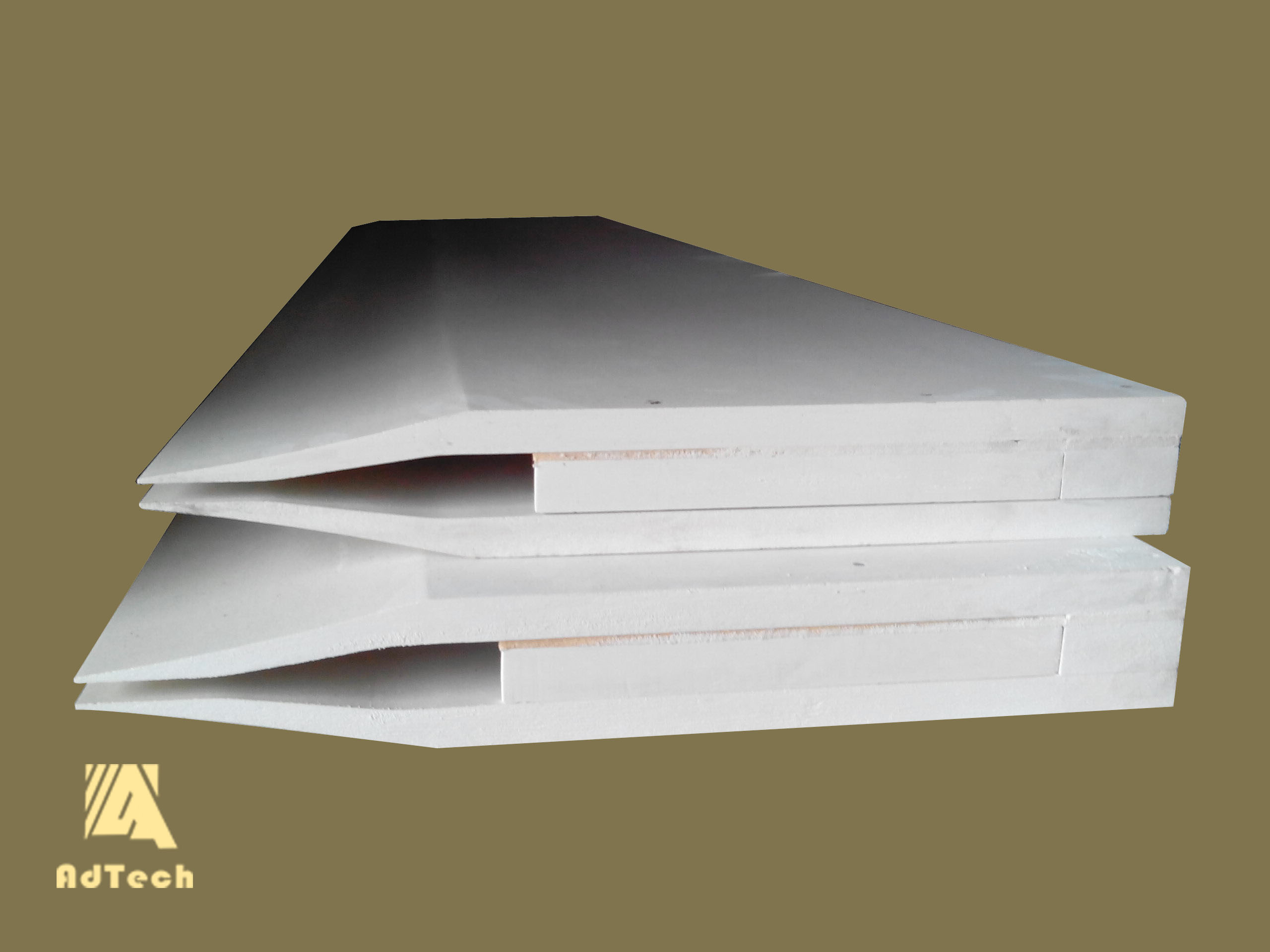

Feed Tip is used for crystal molding and size control of Aluminum Strip Casting in the casting and rolling production line. It is formed by vacuum suction filtration of high-purity fiber materials and processed by precision equipment.

Used in the casting and rolling process of many series of cast-rolled aluminum alloy products: the casting and rolling of micron-level aluminum foil wool, PS base for printing, and elastic packaging materials.

Advantages of Aluminum Strip Casting Feed Tip

Adopting nano-fiber composite material for integral molding, processed by high-precision equipment, precise size control, appropriate density and rigidity.

The key parts are strengthened by nano-coating, and the surface of the hole is sealed, which has good non-delamination and non-stick performance, and enhances the corrosion resistance of aluminum liquid.

Reasonable symmetrical flow channels are designed in the internal structure to meet the requirements of liquid aluminum fluid mechanics.

It has good heat preservation and can effectively control the constant temperature of casting-rolling zone parameters. It is the best choice for casting and rolling high-quality aluminum foil blanks.

Low deformation, easy to adjust the gap between the nozzle and roll, improve the surface quality of the aluminum foil blank, and effectively improve the white stripes and dark lines.

Instructions for use of casting Castertip

Corresponding to the drawing structure, cutting and assembly, to ensure that the nozzle plate is free from damage and cracks.

Before use, place it in a baking oven, heat up at a constant rate for 2 hours to the target value, and keep the Roll-PH controlled temperature at 260°C for more than 5 hours to remove the adsorbed crystal water, cool it to room temperature, and take it out for no more than 2 hours (including Vertical board time) to prevent secondary entry of adsorbed water and ensure safe use of non-destructive installation.

Sorry, the comment form is closed at this time.