08 12月 Filter Box for molten metal

Filter Box for molten metal

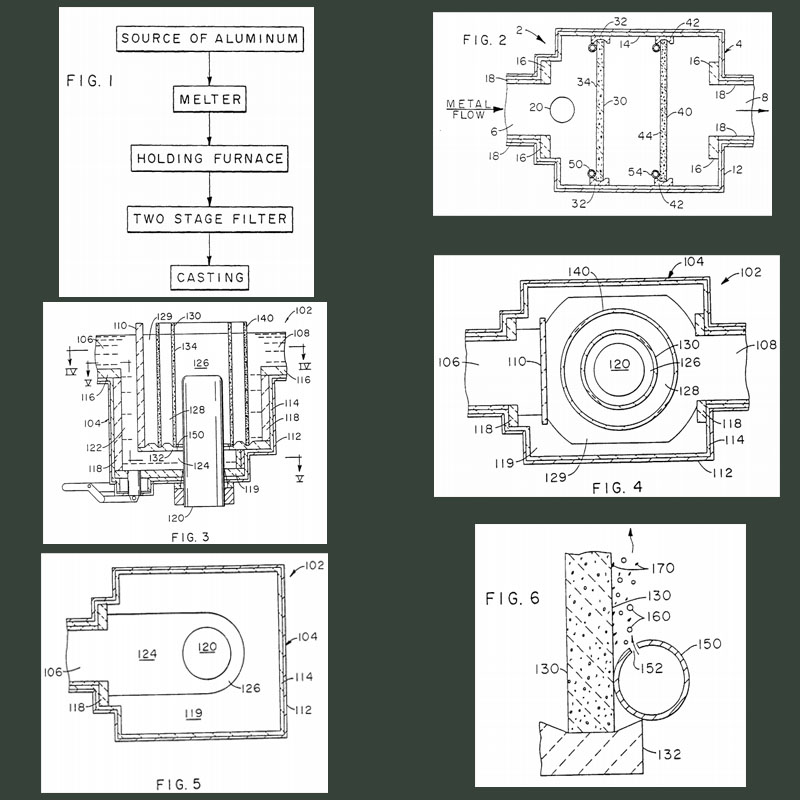

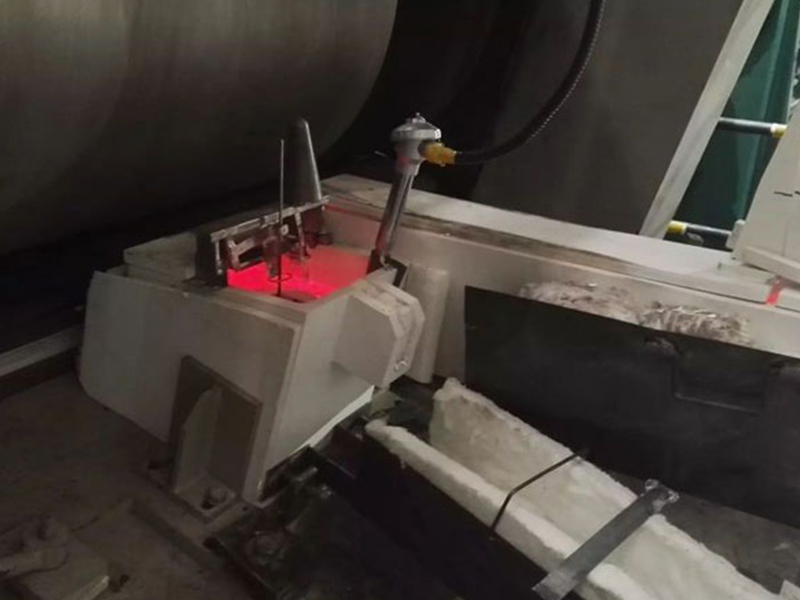

1.The Filter Box of treating molten aluminum containing particles therein to remove the particles from the molten aluminum comprising:

(a) passing said molten aluminum through a first rigid filter media having a first surface to remove a fraction of the particles from said molten aluminum; (b) collecting said particles on said first surface as filter cake, removing the particles from said surface by contacting said first surface or the filter cake with gas bubbles;

(c) passing said molten aluminum from step (a) through a second rigid filter media to remove particles therefrom having a size generally smaller than the particles removed in step (a).

2. The Filter Box in accordance with claim 1, wherein said molten aluminum is passed through filter media having one or more of the following features:

(a) the first filter is a porous ceramic filter formed from bonded ceramic particles having a size in the range of 2 to 18 mesh;

(b) said second filter is a porous ceramic filter formed from bonded ceramic particles having a size in the range of 8 to 36 mesh;

(c) said first and second filters are porous ceramic filters comprised of silicon carbide, silicon nitride or alumina.

3. The Filter Box in accordance with claim 1, wherein the molten aluminum is added to the first filter which defines a first filter box, from which partially filtered aluminum is passed into the second filter which defines a second filter box surrounding the first filter box.

4. The method in accordance with claim 3, wherein filter boxes are used which have one or more of the following features:

(a) the first filter box has walls fabricated from the rigid filter media which are substantially vertical and the molten metal is filtered therethrough in a generally outward direction;

(b) the second filter box has walls fabricated from the rigid filter media which are substantially vertical and through which the molten metal is filtered in a generally outward direction;

(c) the first filter box is generally circular;

(d) the second filter box is generally circular.

5. The Filter Box in accordance with claim 1, wherein particles having a size of 10 microns or greater are removed by passing the molten aluminum through the first rigid filter media and particles having a size less than 10 microns are removed by passing the molten aluminum from the first filter media through the second rigid filter media.

6. The Filter Box in accordance with any one of the preceding claims, which comprises removing filter cake from the first surface of the first rigid filter media by intermittently contacting said first surface with gas bubbles.

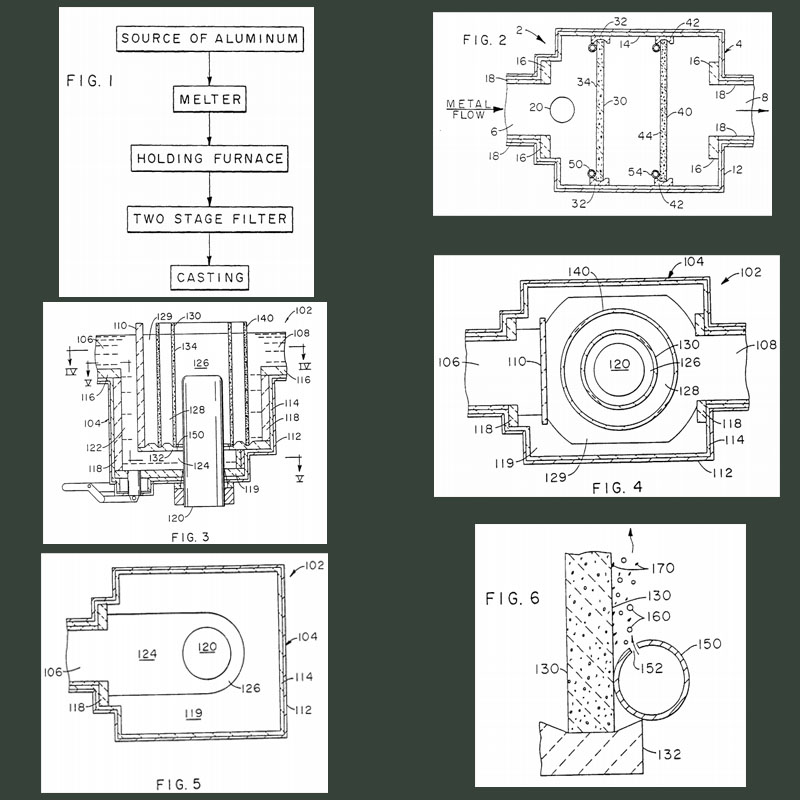

7. The Filter BOX. Apparatus for filtering a molten metal to remove solids therefrom which comprises:

(a) a filter box (4) having an inlet port (6) and an outlet port (8);

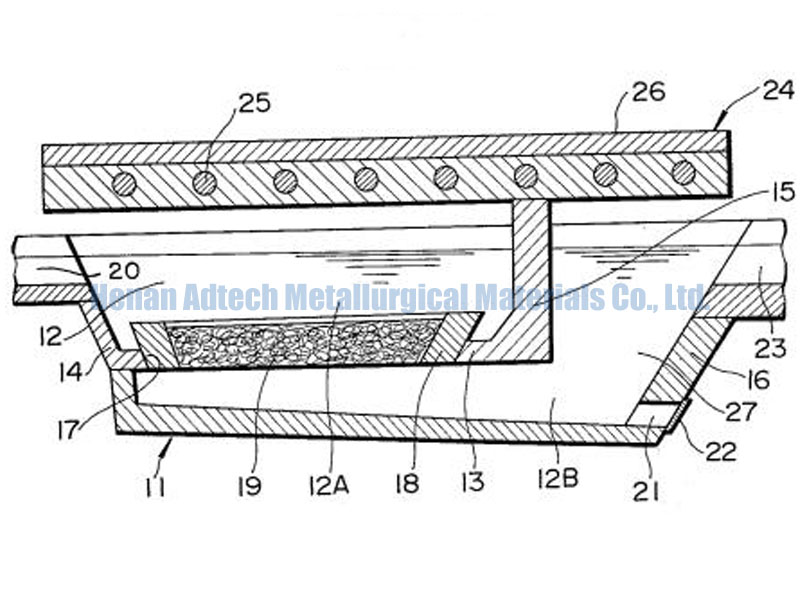

(b) rigid coarse filter means (30) within said housing capable of removing solids having a particle size of at least 10 microns;

(c) rigid fine filter means (40) within said housing capable of removing solids having a particle size of at least 1 micron; and (d) means (50, 150) for directing a flow of gas toward a front face (34, 134) of the rigid coarse filter means (30, 130) to dislodge filter cake therefrom.

8. The apparatus of claim 7, wherein the filter means have one or more of the following features:

(a) said rigid coarse filter means (30) comprises a porous filter having an average grain size of about 2 to 18 mesh;

(b) said rigid fine filter means (40) comprises a porous filter having an average grain size of about 6 to 28 mesh;

(c) said coarse (30) and fine (40) filter means are mounted vertically in said filter housing (4)

(d) the filter means are cylindrical and comprise cylindrical rigid coarse filter means (130) which has a diameter smaller than cylindrical rigid fine filter means (140), said coarse filter means (130) is mounted in said filter housing (104) within said fine filter means (140), and passage means (122, 124) in said housing are provided to direct the flow of molten metal from said inlet port (106) to an inner surface (134) of said coarse filter means (130).

9. The apparatus of claim 8, wherein a heater means (120) is positioned within said cylindrical rigid coarse filter means (10) to heat said molten metal before it passes through said coarse filter means (130).

10. The apparatus of any one of claims 7 to 9, wherein said means for directing a flow of gas across the face of said filter comprising sparger means (50, 150) having openings (152) therein facing said front face (34, 134).

No Comments