11 7月 Filter Foam Ppi

Filter Foam Ppi

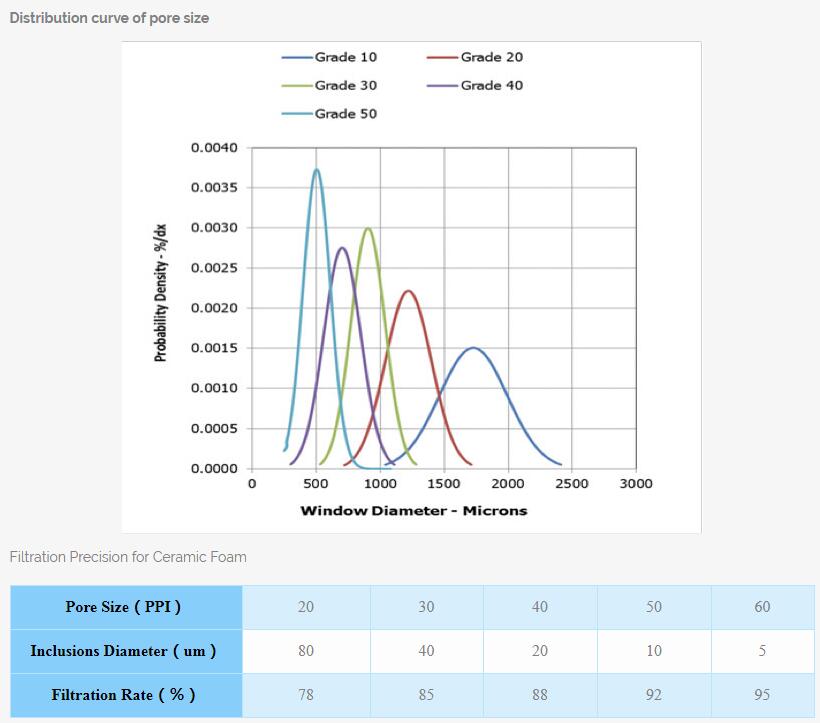

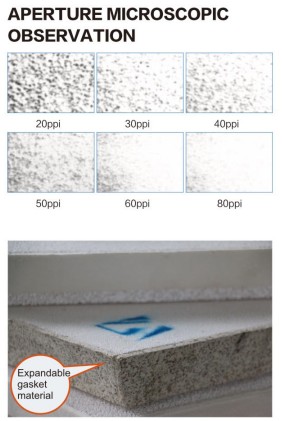

Filter Foam Ppi refers to the number of honeycomb holes on a square inch of Ceramic Foam Filter.

The Filter Foam Ppi 30 means 30 small holes in one square inch. The larger the value, the smaller the hole.

Generally, 15-20 Filter Foam Ppi means a large hole, 25-30 Filter Foam Ppi is a medium hole, and 35 Filter Foam Ppi or more is a small hole.

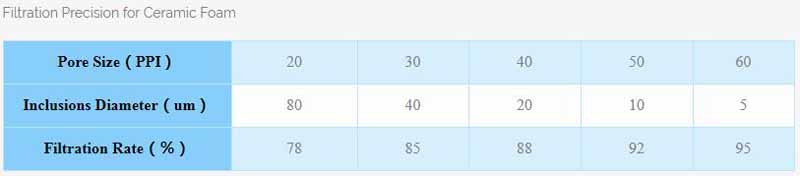

Filtration Precision for Filter Foam Ppi

Pore Size(PPI) 20 30 40 50 60

Inclusions Diameter(um) 80 40 20 10 5

Filtration Rate(%) 78 85 88 92 95

Ceramic Foam Filter transmittance

Transmittance refers to the effective filtration area of the foam ceramic filter plate product. The higher the light transmittance, the fewer blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb, and the square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the area of the large surface of the filter plate, so as to calculate the test. The light transmittance of the filter plate is used to determine the light transmittance of the filter plate. In this standard, the transmittance (through-hole ratio) of the filter plate is specified to be 95% or more.

Ceramic Foam Filter Porosity

Porosity is the percentage of the total volume of the cavities in the filter plate product to the total volume of the filter plate product. Porosity determines the filtration capacity of the foam ceramic filter plate per unit volume. The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity.

There are currently two main methods for determining porosity

One is to calculate the volume of the hole in the filter plate according to Archimedes’ law, that is, to inject water into the glass beaker with the overflow pipe until the water flows out from the overflow pipe, and the water will be tested when the water is no longer flowing out. All the samples are gently placed in the water, then the water flows out of the overflow tube, and the volume of water in this part is measured. The volume of the overflow water is subtracted from the physical volume of the filter plate, which is the total volume of the holes in the filter plate. volume.

Another method is to separately determine the true density and bulk density of the sample to be tested, and then calculate the porosity of the sample according to the following formula.

These two methods have their own advantages and disadvantages. The method of operation is simple and convenient, and the detection speed is fast, but its fatal weakness is due to the water absorption characteristics of the filter plate material itself so that the volume of water discharged is smaller than the actual one. This causes the measured data to be too small.

Although the test process of the second method is more complicated, the influence of the water absorption of the filter plate material is excluded during the test, and the obtained data is relatively accurate.

The index of porosity is determined to be greater than 84% in this standard.

Thermal shock resistance of Ceramic Foam Filter

Thermal shock resistance refers to the resistance of foam ceramic filter plates to damage caused by rapid temperature changes. During the use of the foam ceramic filter plate, we require the user to start the filtration when the filter plate is gradually preheated to the temperature of the filtered aluminum melt before use, but some users do not follow this well when using it. It is stipulated that after the filter plate is placed, the melt is filtered without preheating so the filter plate is required to have a certain thermal shock resistance. The better the thermal shock resistance, the more durable the filter plate and the better the quality.

Ceramic Foam Filter Pore uniformity

Pore uniformity is used to describe the difference between the number of actual holes per 25.4 mm length in the filter plate product and the number of theoretically required holes.

The smaller the gap, the better the product quality, and if the gap is too large, it will result in the ability of the filter plate product to reduce the impurity retention or the slow filtration rate of the melt, which can not meet the individual requirements of the user’s production.

The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The uniformity of the pores of the foam is good, and the uniformity of the pores of the filter plate is good, so the selection of the foam is extremely important.

Ceramic Foam Filter compressive strength

In the process of transportation and use of the filter plate, the filter plate must withstand the impact of a certain pressure from the outside, so the index of compressive strength is also introduced in the standard as one of the bases for measuring the quality of the filter plate. The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

In this standard, the index of compressive strength is determined to be 0.5 MPa or more.

Instructions for Ceramic Foam Filter

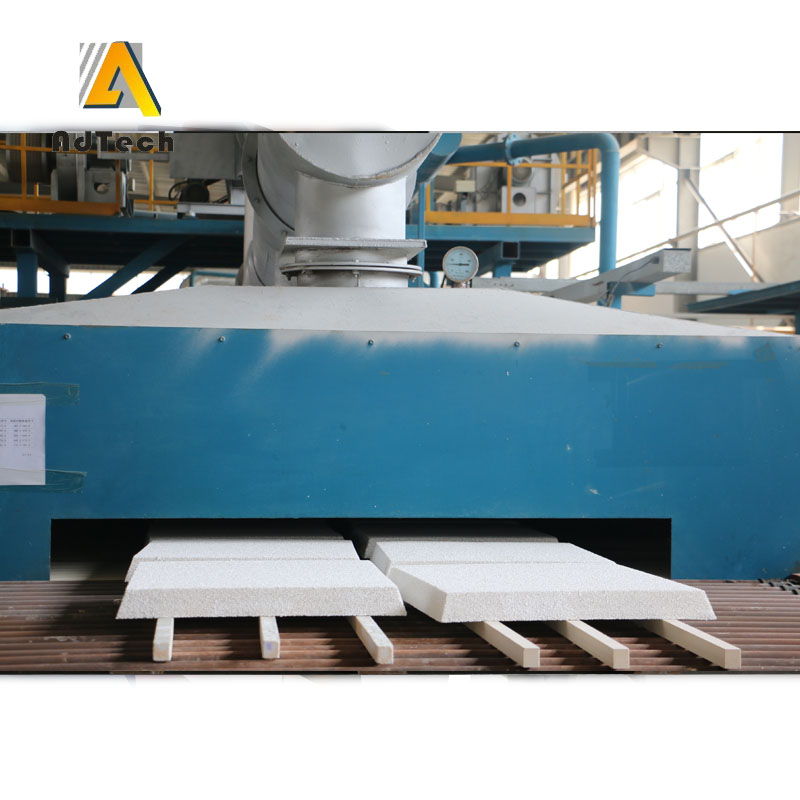

Inspect and clean the surface of the filter bowl, and keep it clean and intact.

Gently lay the filter in the filter bowl, and press the sealing gasket around the filter by hand to prevent molten aluminum from dispersing or floating away.

Use electric or gas burning to preheat the filter bowl and ceramic foam filter evenly for 15-30 minutes, making sure their temperature is close to molten aluminum. The preheating temperature for the ceramic foam filter should be above 260℃. Expanding cotton will seal after preheating. This procedure makes the ceramic foam filter steadily fixed in molten aluminum. Preheating also leads ceramic foam filter pores to open and avoid occlusion caused by thermal expansion and contraction.

Observe the change of molten aluminum height, and hold molten aluminum flow in standard needs. Normal starting molten aluminum height is 100-150mm. The height falls down below 75-100mm when molten aluminum flows, and it will slowly increase later.

Do not hit or shake ceramic foam filter infiltration. At the same time, control the molten aluminum flow rate in the launder, never to be too much or too little.

Take out the ceramic foam filter and clean the filter bowl in time after filtering.

Sorry, the comment form is closed at this time.