16 4月 Flux Aluminium

Flux Aluminium

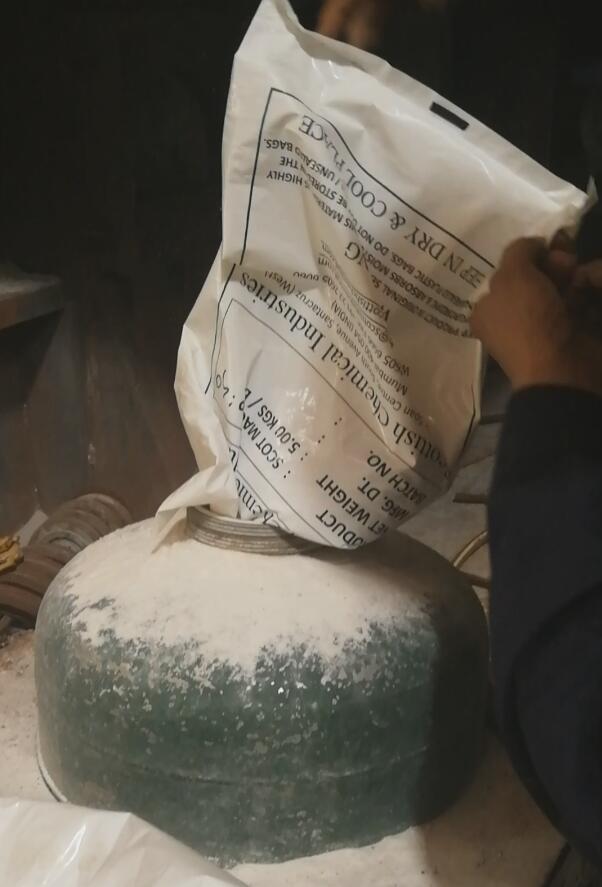

Flux Aluminium is a white powdery fine particle. The main components are chlorine salt and fluoride salt, and other compounds, which are properly heat treated and sieved, have uniform particle size.

Conducive to the uniformization of the refining tank under the action of carrier gas (N 2 or Ar) into the lower layer of aluminum liquid, through the physical and chemical changes in the formation of numerous small bubbles in the aluminum liquid and aluminum liquid in full contact, separation of [H] in the aluminum liquid Other harmful gases.

Some substances contained in Flux Aluminium can strongly adsorb and melt the oxides and suspended solids in the melt and adhere to the bubbles together, and bring them to the surface of the aluminum liquid as the bubbles rise, thereby achieving refining and purifying such as degassing and slag removal. the goal of.

Flux Aluminium is dedicated to the development, production and sale of refining agents for the degassing and slagging of molten metal in aluminum alloy casting processes.

AdTech’s refining agent uses a unique technology to enhance the traditional degassing and slag removal effect in molten metal.

Used in the casting and rolling process of multi-series aluminum alloy products: micron-sized aluminum foil wool, PS board base for printing, cans, elastic packaging materials, rail transit, aerospace products, cable wires, etc. Liquid degassing and slag purity purification.

Flux Aluminium uses a combination of metal liquid compounds to develop and configure products to reduce smoke, reduce burnout, and environmentally friendly;

Adtech Flux Aluminium solves the problem of refining effect in the traditional use of high aluminum ash. AdTech’s refining agent is 1.5-2.0kg per ton of aluminum, and the amount of aluminum ash is 0.8-1%, which meets the requirements of high-precision aluminum alloy casting. Effectively increase the yield of molten metal by 0.6-0.8% to achieve energy saving and consumption reduction;

Flux Aluminium is properly heated and sieved out, and the particle size is uniform, which is beneficial to the uniformization of the refining tank under the action of carrier gas (N 2 or Ar) into the lower layer of aluminum liquid, which fully solves the traditional blocking and failure to evenly disperse. Not conducive to ensuring casting quality and other issues.

No Comments