27 8月 Foam Ceramic Filter Inalum

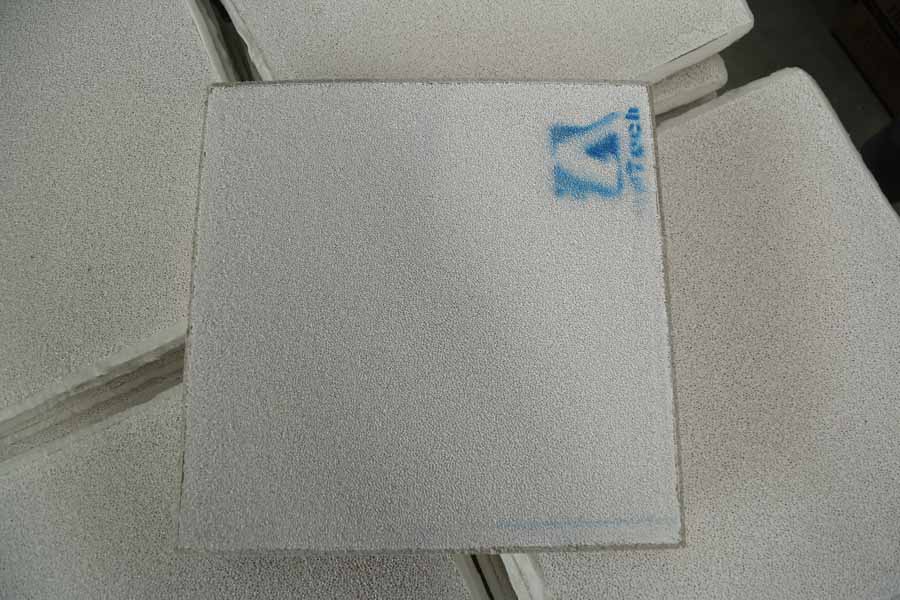

Foam Ceramic Filter Inalum is mainly used in the filtration process of aluminum and alloys in foundries and foundries.

It has excellent resistance to molten aluminum erosion and corrosion, and can effectively remove inclusions.

These impurities are easy to produce bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, and then affect the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

Foam Ceramic Filter Inalum is white or milky white.

Through physical adsorption and chemical action, it is suitable for the production of high-quality, high-demand aluminum and aluminum alloy purification processes. It can effectively remove various oxidized inclusions generated during the aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high- High-quality materials for further processing.

Filters in aluminum plants should be preheated before use.

The main features of Foam Ceramic Filter Inalum are as follows

1. The filtration accuracy covers fine filtration and micro filtration.

2. High mechanical strength, stable chemical performance, good wear resistance, low resistance and anti-clogging.

3. High efficiency, high output, beautiful arrangement of filter apertures, uniform and neat.

Keywords=Molten Aluminum Filter,Ceramic Foam Filte,Ceramic Filter Plate,Porous Aluminum plate,Silicon Carbide Ceramic Foam Filter,Alumina Ceramic Filter,Alumina Foam Filters,Molten Metal Filtration,Cast House Filter,casting filter.

ADTECH focus on Metallurgical Material

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

PT Indonesia Asahan Aluminum (Inalum) announced that it will improve its aluminum smelting furnace technology with the help of three EPC companies, SAMI, PT Waskita Karya (Persero) and PT Unefeco. The news was released after Sophia Issabella Watimena, executive director of PT Inalum (Persero) in Kuala Tanjung, officially announced the news. At the same time, the addition of improvement items will increase the operating current of the smelting furnace to 235 kA instead of 193 kA.

Inalum improves its aluminum smelting furnace technology; seeks support from 3 EPC companies

Improvements will be implemented in electrolysis cell 1 and up to 170 furnaces, thereby increasing Inalum’s aluminum production capacity by 25,000 tons per year.

Sophia Issabella Watimena said, “With the technological improvement of electrolytic cell 1 with as many as 170 furnaces, Inalum’s production capacity is expected to increase by 25,000 tons of aluminum per year.”

He added that in addition to this, Inalum is currently undertaking other development projects, such as the construction of a smelter-grade alumina refinery in Mempawah, West Kalimantan, and the feasibility study process for the construction of a CPC plant.

SAMI CEO Ma Ning praised Inalum: “We are very pleased to cooperate with Inalum on the improvement of aluminum smelting furnace technology. We believe that the good cooperation between the participating companies, then the aluminum smelting furnace technology improvement project can be achieved as expected Like that.”

No Comments