02 9月 Foam Ceramic Filter Irkutsk Aluminium

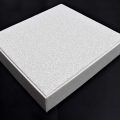

Foam Ceramic Filter Irkutsk Aluminium has an open-cell structure made of molten ceramic foam, which is characterized by several interconnected cavities surrounded by ceramic fabric.

Among them, the density of the foamed ceramic material is less than 30% of the theoretical density of the membrane. Ceramic material. The same size.

Of course, the ceramic foam can have any desired configuration based on the configuration required for a particular molten metal filtration process.

When melting, refining and forming metals, especially when casting molten metal, it is desirable to separate inclusions from molten metal.

Advantages of Foam Ceramic Filter Irkutsk Aluminium

1. Adopt the principle of adsorption to filter. The alumina ceramic foam filter can effectively remove the larger inclusions in the molten aluminum and effectively adsorb the micron-level fine inclusions. Under the same mesh size, it has a higher filtration accuracy.

2. No slag drop, effectively reducing the pollution of molten aluminum.

3. It has good thermal shock resistance and molten metal corrosion resistance.

4. Automatic production line, three calibration procedures, accurate size, more suitable for filter box.

5. Improve surface quality, product performance and microstructure.

Irkutsk Aluminium bought Foam Ceramic Filter through sales@adtechamm.com

This storage of impurities results in the formation of raw materials of slag, scum and oxide melts and small fragments of refractory materials in the form of slag, scum and oxides on the surface of the slag.

A container used to form a chamber or container in which molten metal is formed.

Failure to remove these inclusions from the molten state of the metal can lead to weakening of the tip and/or reduced porosity of the final solidified metal body (the final product of the casting process).

Some inclusions in aluminum alloy come directly from batch materials, most of which are formed during melting and casting, mainly oxide inclusions.

All precast inclusions are called primary oxidation inclusions, and can be divided into two categories according to their size: one is the large inclusions with uneven distribution in the macrostructure, which makes the alloy structure discontinuous and reduces the compactness of the casting. Become a source of corrosion and cracks, significantly reducing the strength and plasticity of the alloy; the other is very short

Dispersed inclusions, which cannot be completely removed after refining, increase the viscosity of the molten metal and reduce the feedability of the molten aluminum during the solidification process.

Secondary oxidation inclusions mainly appear in the casting process. During the casting process, liquid aluminum contacts air, and oxygen reacts with aluminum to form oxide inclusions.

During the melting process, the aluminum alloy comes into contact with various components in the furnace gas to generate compounds such as AL2O3.

The Al2O3 in the molten aluminum increases the hydrogen content of the molten aluminum alloy. Therefore, the content of Al2O3 in the aluminum melt has a great influence on the formation of pores in aluminum castings.

No Comments