01 9月 Foam Ceramic Filter Jsc Aluminium

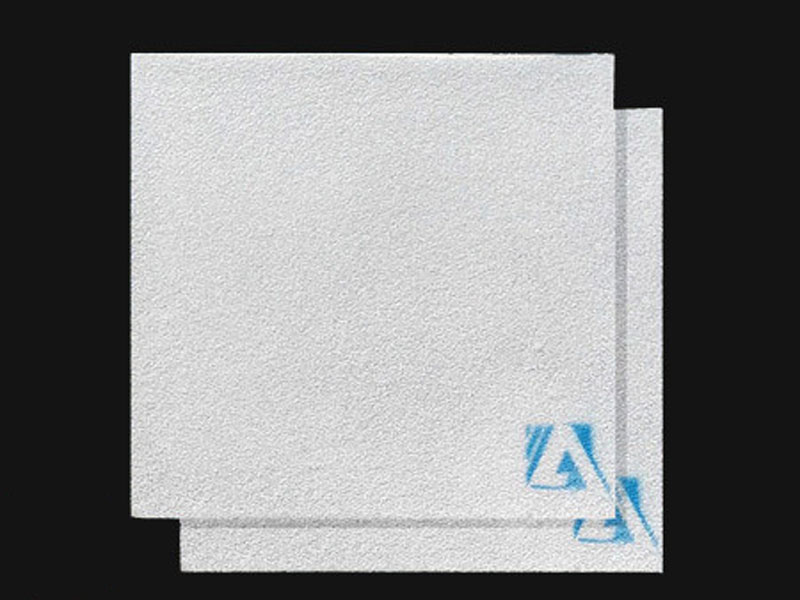

Foam Ceramic Filter Jsc Aluminium is manufactured on the basis of a carrier with a fixed network structure and organic foam cells, and is used for the filtration and purification of molten aluminum.

The foam filter is mixed into the thixotropic alumina slurry through an automated production line, and the slurry is evenly deposited on the foam skeleton of the carrier after being dried and solidified. It is then fired at a high temperature of 1180°C to form the final product.

Aluminum has good light reflectivity and reflects ultraviolet rays more strongly than silver. The purer the aluminum, the better the reflectivity. The vacuum aluminizing process is widely used to manufacture high-quality mirrors. Vacuum aluminum plating

The combination of the thin film and the polysilicon thin film becomes a cheap and light solar cell material. Aluminum powder can maintain silver-white luster and is widely used in the manufacture of coatings, commonly known as silver powder.

Foam Ceramic Filter Jsc Aluminium is used to filter the impurities in molten aluminum alloy, helping to meet the production requirements of high-quality precision castings made of high-tech aluminum alloys (such as computer hard drives, PS substrates). Used for printing, preserving materials, turbojet fan blades, etc.

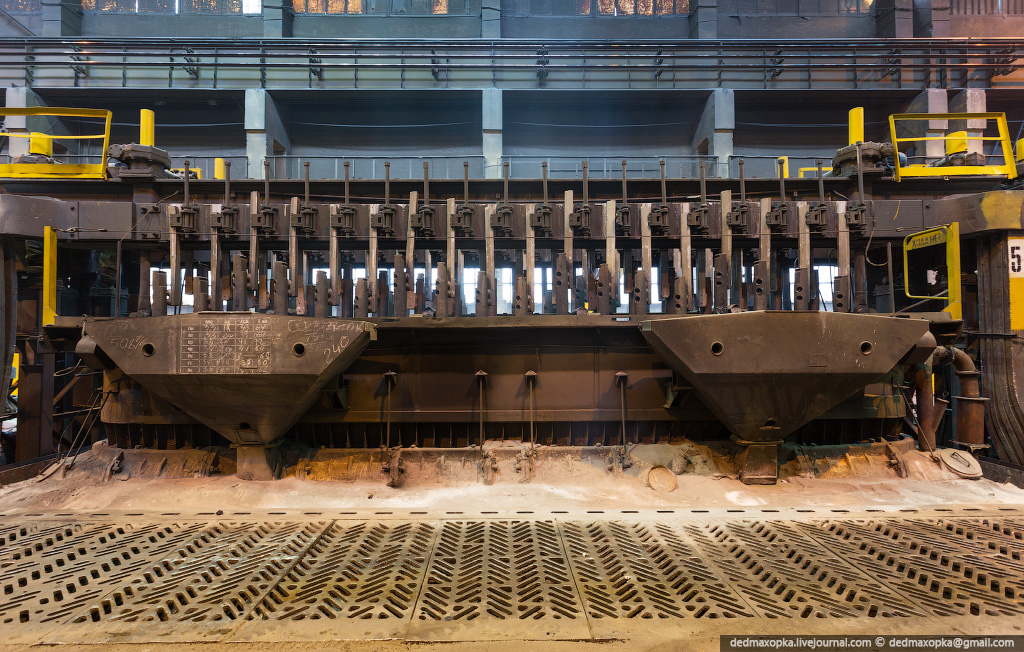

Ceramic foam filters can remove large amounts of such inclusions from molten aluminum. Foam ceramic filtration technology has become the main method of filtering commercial aluminum alloys worldwide.

Because of its low installation and operating costs and ease of use, the technology quickly expanded to aluminum foundries of various types and levels of complexity.

Over the years, it has been steadily developing towards the use of finer pore ceramic foam filters to provide higher melt cleanliness, which is a requirement for the continuous improvement of the quality of aluminum processed products.

For example, in the application of aluminum can body panels, 40 and 50 holes per inch (PPI) foam filters are now commonly used in panel production.

In addition, a finer pore filter is currently being evaluated.

However, the use of finer pore filters requires a lot of pretreatment to reduce the level of inclusions and prevent the filter from clogging prematurely or blocked by residual inclusions.

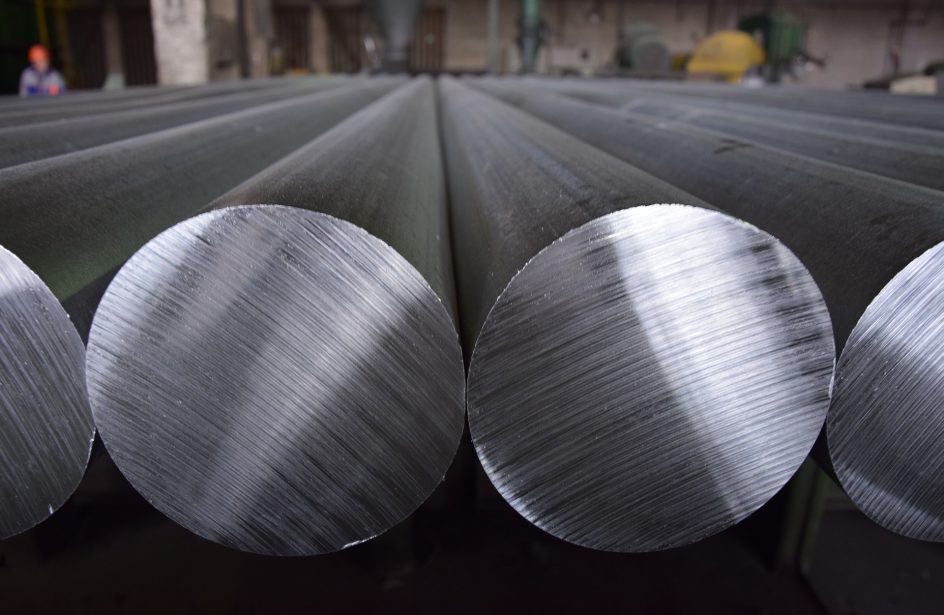

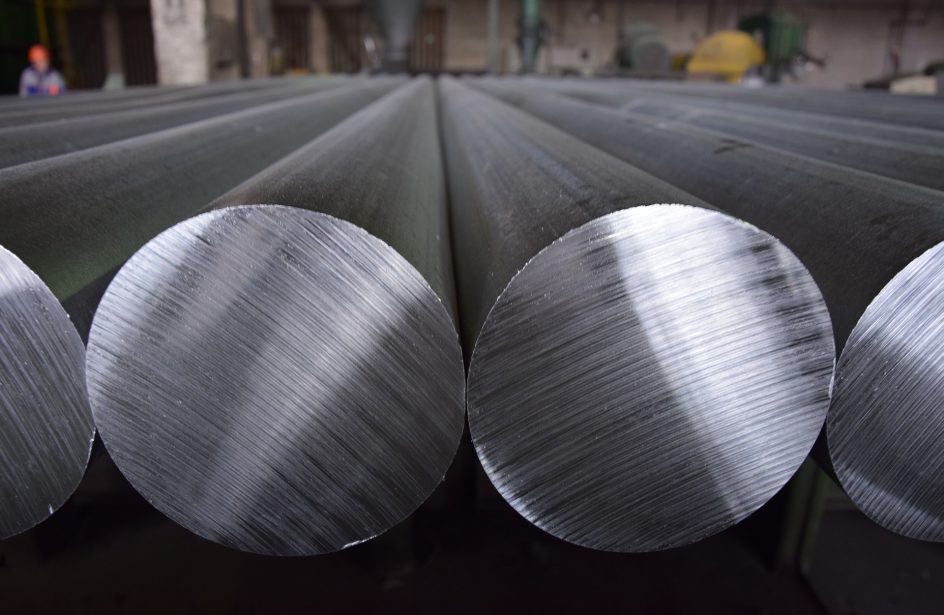

Solid particles such as oxides, carbides, nitrides, and borax compounds present in metals (such as aluminum) and insoluble inclusions in liquids (such as molten salts) will significantly affect the plasticity and the final metal during rolling or extrusion deformation. Surface Quality.

No Comments