17 9月 Foam Ceramic Filter Spain Aluminium

Foam Ceramic Filter Spain Aluminium has a large flow capacity and is suitable for filtration and purification in continuous casting and rolling production.

The metal filters and fiber cloth filters used by low-end customers can only remove large inclusions in the aluminum alloy melt, but cannot remove the inclusions below micrometers. The metal filter will contaminate the aluminum alloy. Ceramic Filter For Foundry can filter out fine inclusions and significantly improve the mechanical properties and appearance quality of the product.

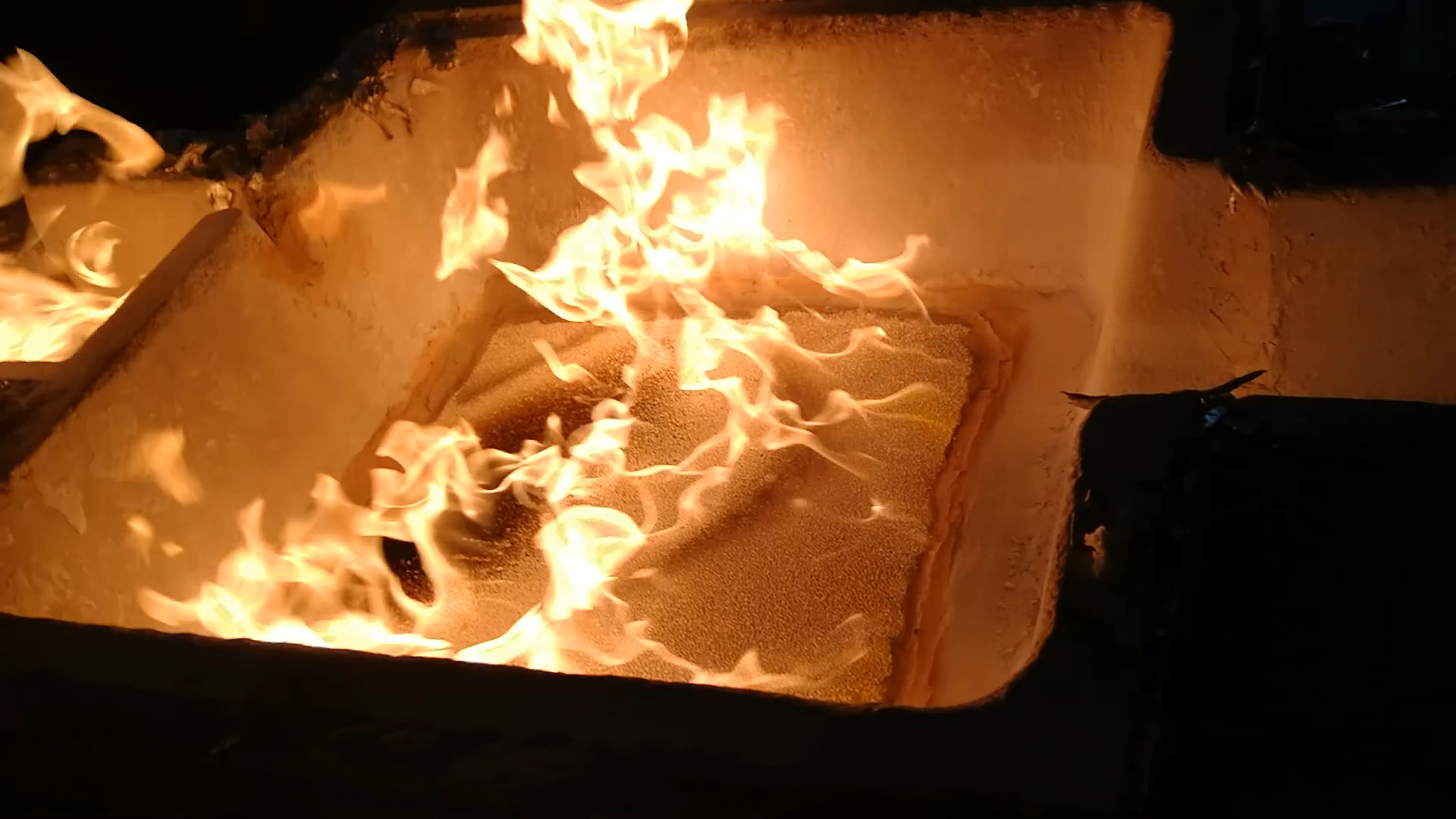

When using Foam Ceramic Filter Spain Aluminium, if the melt is very dirty, the filter will quickly become clogged.

Using two filters can extend the life of the filter.

In terms of filtration efficiency, it is far more effective to increase the collection efficiency by increasing the filtration area than adding a coarse filter to it.

A more effective arrangement is to place two large-area fine filters in parallel at the outlet of the launder, instead of using one thick and one thin in series.

Choose filter materials of different thicknesses to change their ability to capture inclusions.

Use filter materials of different pore sizes to make a reasonable combination from large pores to small pores, that is, at the same time change the filtration parameters, increase the filtration thickness and the number of filtration stages to enhance the ability to capture inclusions.

Increase the flow cross-sectional area, reduce the flow rate of the melt, increase the probability of capturing inclusions, etc., to improve the filtering effect to achieve the desired purpose.

UCIN ALUMINIUM is an independent company founded in 1967 by Jose María Ucín. Over the years, the company has gone through different stages, starting from manufacturing aluminum tubes and profiles.

In 1974, the company moved to the actual location, where the complete cycle of 60.000 square meters of aluminum renovation was completed. Casting, hot and cold rolling, stretch straightening, cutting and manufacturing of various finished products. Over the years, the width of the coil has also been changing, from the first 500 mm, later to 1000 mm, and then to the actual 1,250 mm.

No Comments