09 4月 Foam Filter Box System

Foam Filter Box System

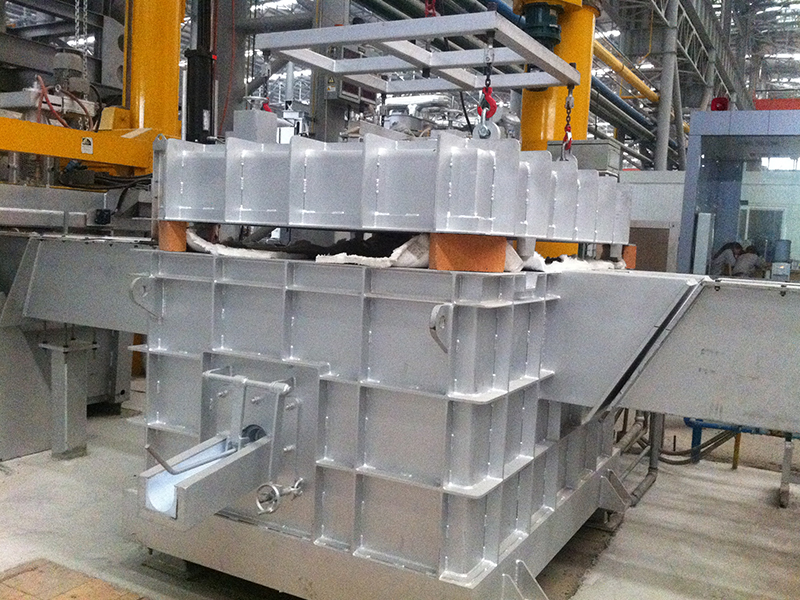

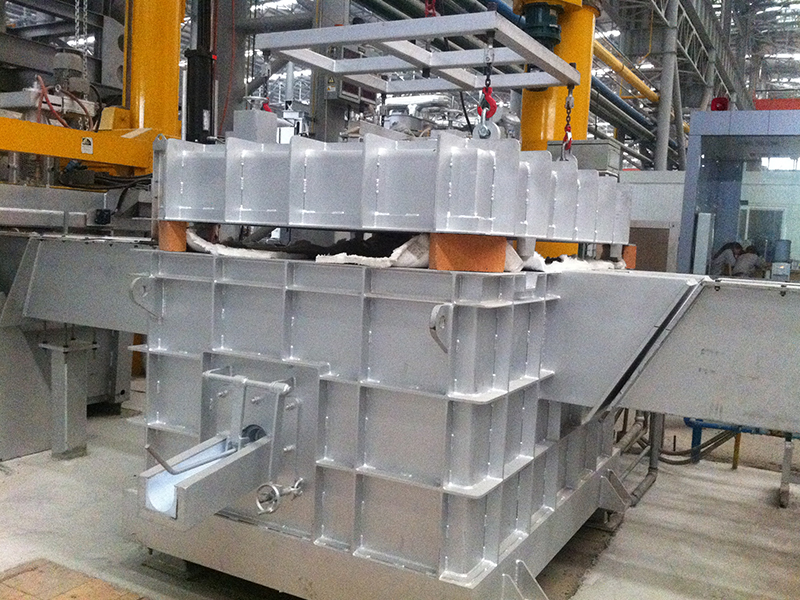

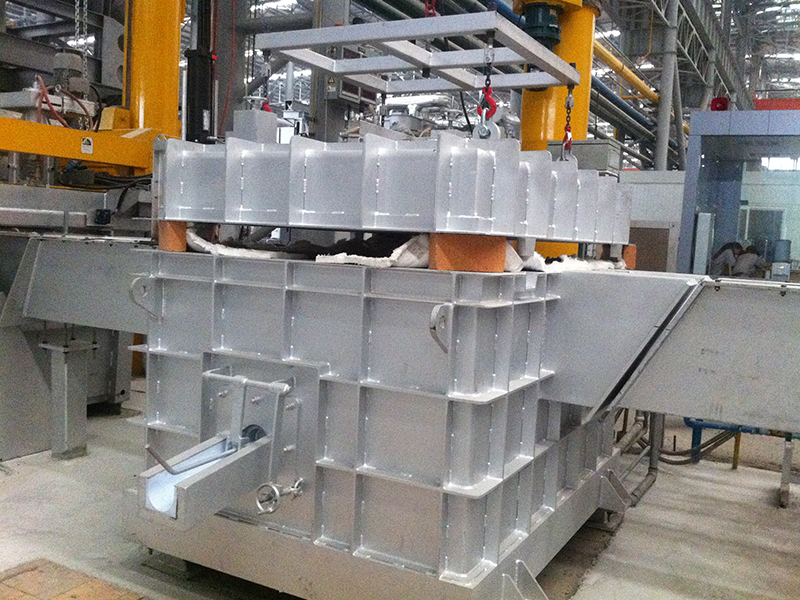

Foam Filter Box System, also called impurity filter, is one of the main equipments for aluminum pretreatment.

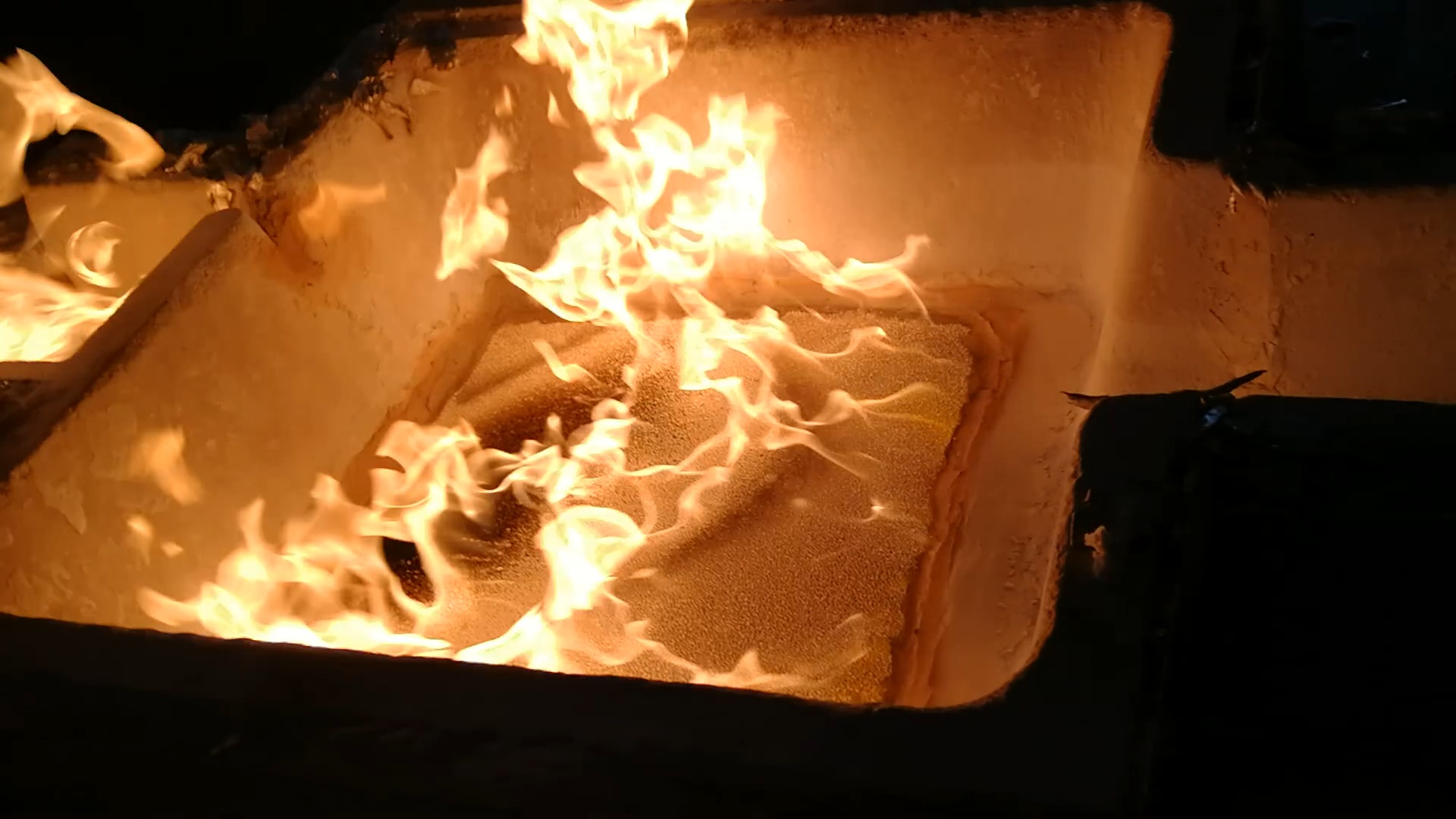

According to the situation of aluminum, the corresponding design scheme is adopted to effectively remove impurities such as suspended solids, sediments and particles in the aluminum liquid and improve the purity of the aluminum.

The Foam Filter Box System is a general term for filtering facilities and refers to the machinery used for filtration. Equipment or devices are common in industrial production.

Foam Filter Box System refers to mechanical equipment or devices used for filtration, and is a common equipment commonly used in industrial production.

Foam Filter Box System Manufacturers advantages and disadvantages:

1. Reasonable size, simple installation and operation, convenient and small floor space;

2. High filtration accuracy, suitable for any fine particles or suspensions, filtration range from 1 ~ 600 microns;

3. The unit filter area has a large processing flow, small filtration resistance, high filtration efficiency, and can greatly reduce costs;

4. The structure is simple, the washing effect is good, the washing liquid is separated from the filtrate, and for the slurry with fast dewatering, the processing capacity of a single filter is large;

5. Disadvantages are: large area, fast filter plate wear;

6. The normal use temperature is 1450°C, and can be used continuously for 2200 hours. It has the characteristics of high temperature resistance, oxidation resistance, corrosion resistance, rapid temperature rise, long life, and strong acid resistance.

7. The outer shell of the equipment is made of welded steel plates, and advanced rust removal and corrosion-resistant coatings are used.

8. With lifting rotary device, small size, high precision, fully synchronized, self-locking performance, good stability, structural stability;

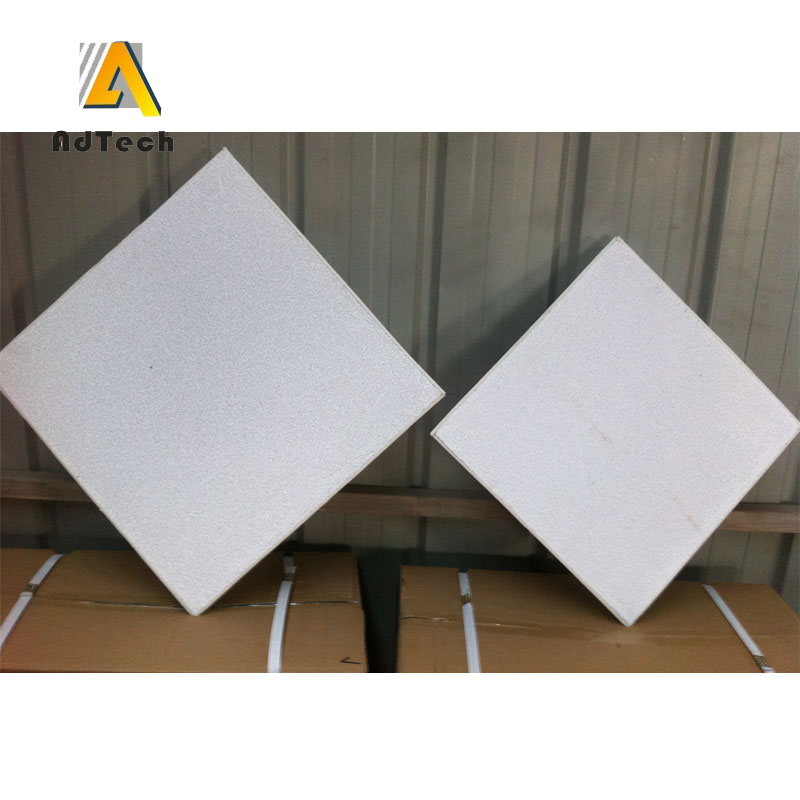

9. The inner lining is made of high-silicon molten material, non-stick aluminum, high corrosion and oxidation resistance, and prolongs the service life. The design of this type of plate filtration equipment is reasonable, and the use of high-absorption ceramic filter plates replaces the ceramics with high cost in the industry. Tube filtration equipment;

Foam Filter Box System

Feeding, filtering, blowing and unloading cakes are performed continuously at the same time. High filtration speed, low moisture content, clean environment, and more suitable for automatic control features.

Drum pressure filter

Continuous operation, low cake moisture content, good washing effect, the current maximum filter area of 5 square meters, operating pressure is about 0.3Mpa. Disadvantages are complex and difficult maintenance and are suitable for large-scale production.

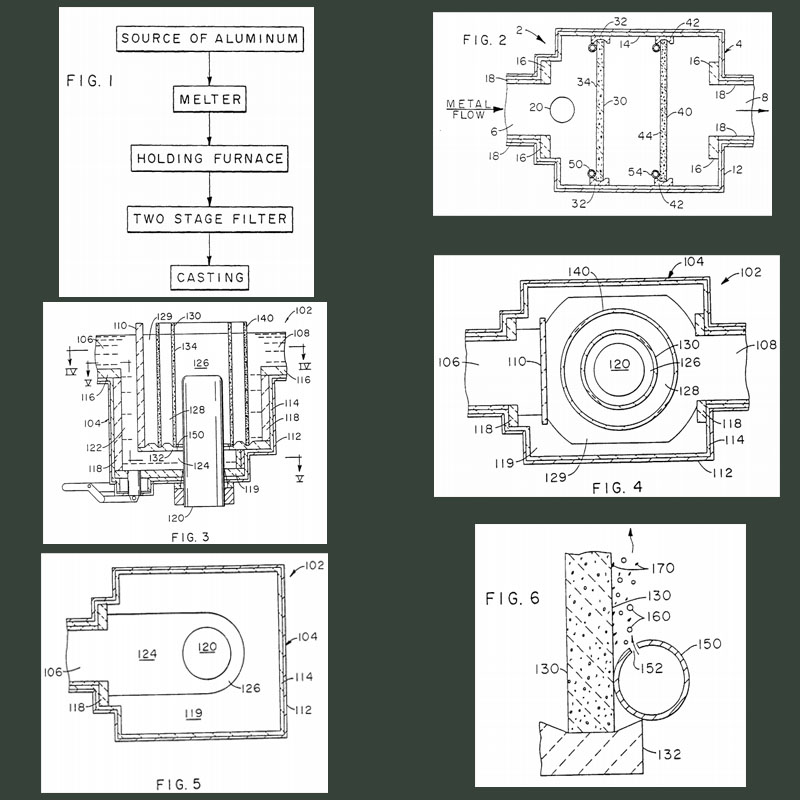

Foam Filter Box System mechanism:

Symmetrical fiber filter structure: The core technology of high-efficiency automatic filter is to use symmetrical fiber bundle material as filter material;

Operating principle

The other end of the fiber tow is fixed in a solid body with a large specific gravity. When filtering, a solid core with a larger specific gravity plays a role in compacting the fiber tow, and at the same time, due to the smaller size of the nuclei, the distribution of the porosity of the filter section is Uniformity has little effect, thereby improving the filter bed’s ability to intercept dirt.

The filter bed has the advantages of high porosity, small specific surface area, high filtration speed, large amount of sewage interception, and high filtration accuracy. When the suspension liquid in the aluminum liquid passes through the surface of the fiber filter material, it is under the action of gravity and electrolysis. , Suspension solids and fiber bundle adhesion is much greater than the adhesion with quartz sand, help to improve the filtration rate and filtration accuracy.

No Comments