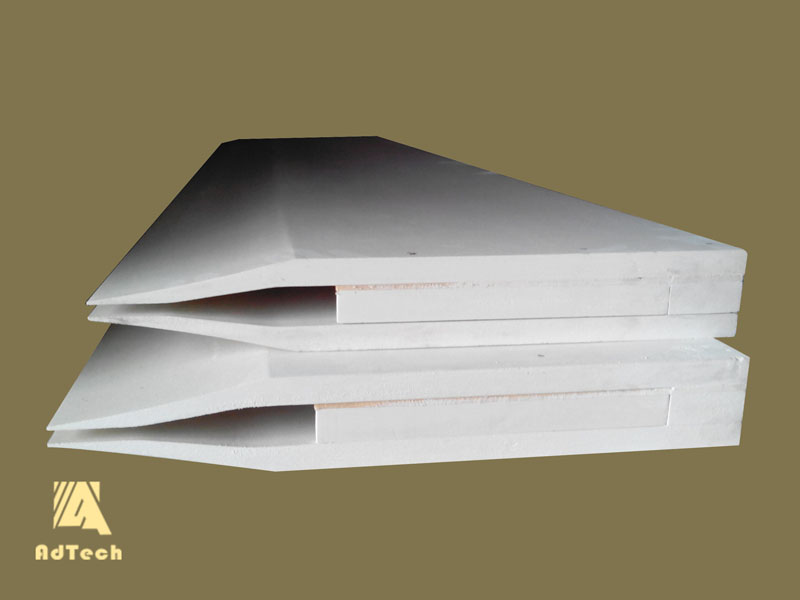

20 2月 Foam Filter Manufacturers Product

Foam Filter Manufacturers Product, as we all know, is mainly used for the filtration of aluminum and alloys in foundries and foundries.

Due to its excellent resistance to corrosion and corrosion by molten aluminum, the filter can effectively remove inclusions, reduce residual gas and provide laminar flow.

Therefore, the filtered aluminum metal is significantly cleaner and the metal can produce higher quality castings, less waste and fewer inclusion defects

Foam Filter Manufacturers Product has the following advantages, which all help increase profits.

-Reduce waste related to inclusions.

-Reduce costs related to inclusion of defects.

-Improve productivity through higher extrusion or rolling speeds.

-Increase casting flexibility, easy to replace alloy.

Characteristics of Foam Filter Manufacturers Product

*Superior dimensional tolerance

*Stable chemical composition

*Highest filtration efficiency

*powerful

*Resistant to corrosion of molten aluminum and alloys

*Beveled edges and compressible gaskets

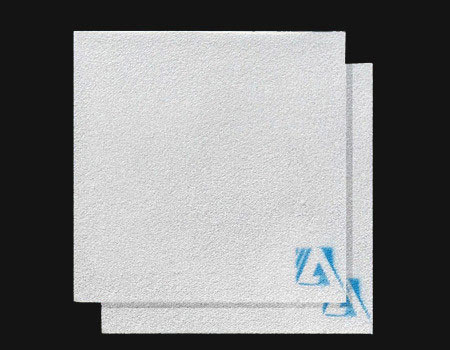

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Ceramic Fiber Castertip

Ceramic Fiber Castertip is the key parts of the continuous aluminum trip casting machine which directly effect the quality of aluminum sheets. The castertips can be divided into many types according to different casting machines. Aluminum silicate caster tips produced by our plant is compounded by ceramic fiber and some other refractory materials.

Features

1. Excellent heat preservation.

2. High strength of anti-flex and anti-pressure.

3. Excellent thermal shock resistance.

4. Smooth surface, non stick aluminum.

5. Good insulation, non-deforming.

Popular type

1, for tilting continuous casting and rolling machine

2, for horizontal continuouscasting and rolling machine

3, for up-draft casting tips

4, for hazelett cating tips

The opening surface and the coating of the working surface are smooth and it can resistant to the corrosion of the liquid aluminum , guarantee the purity of the aluminum sheet . Castertips with excellent non-wetting properties, low thermal conductivity, high temperature stabilities, uniform density, smooth surfaces and close tolerance, is superior products for continuous aluminium strip casting.

Ceramic Fiber Castertip with excellent non-wetting properties, low thermal conductivity, high temperature stabilities, uniform density, smooth surfaces and close tolerance, is superior products for continuous aluminium strip casting.

No Comments