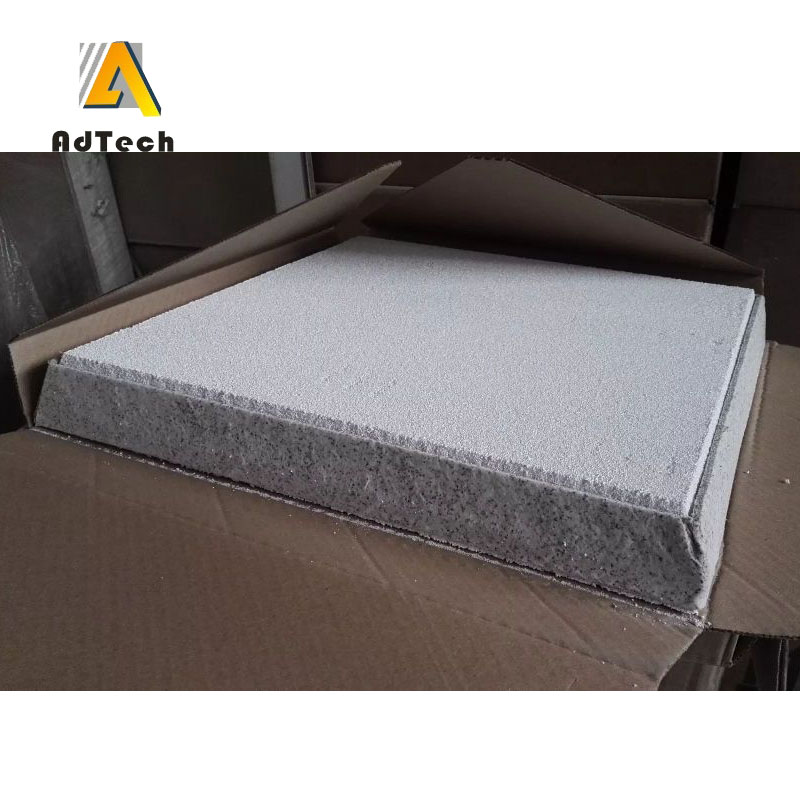

29 10月 For Aluminium Casting Filtration

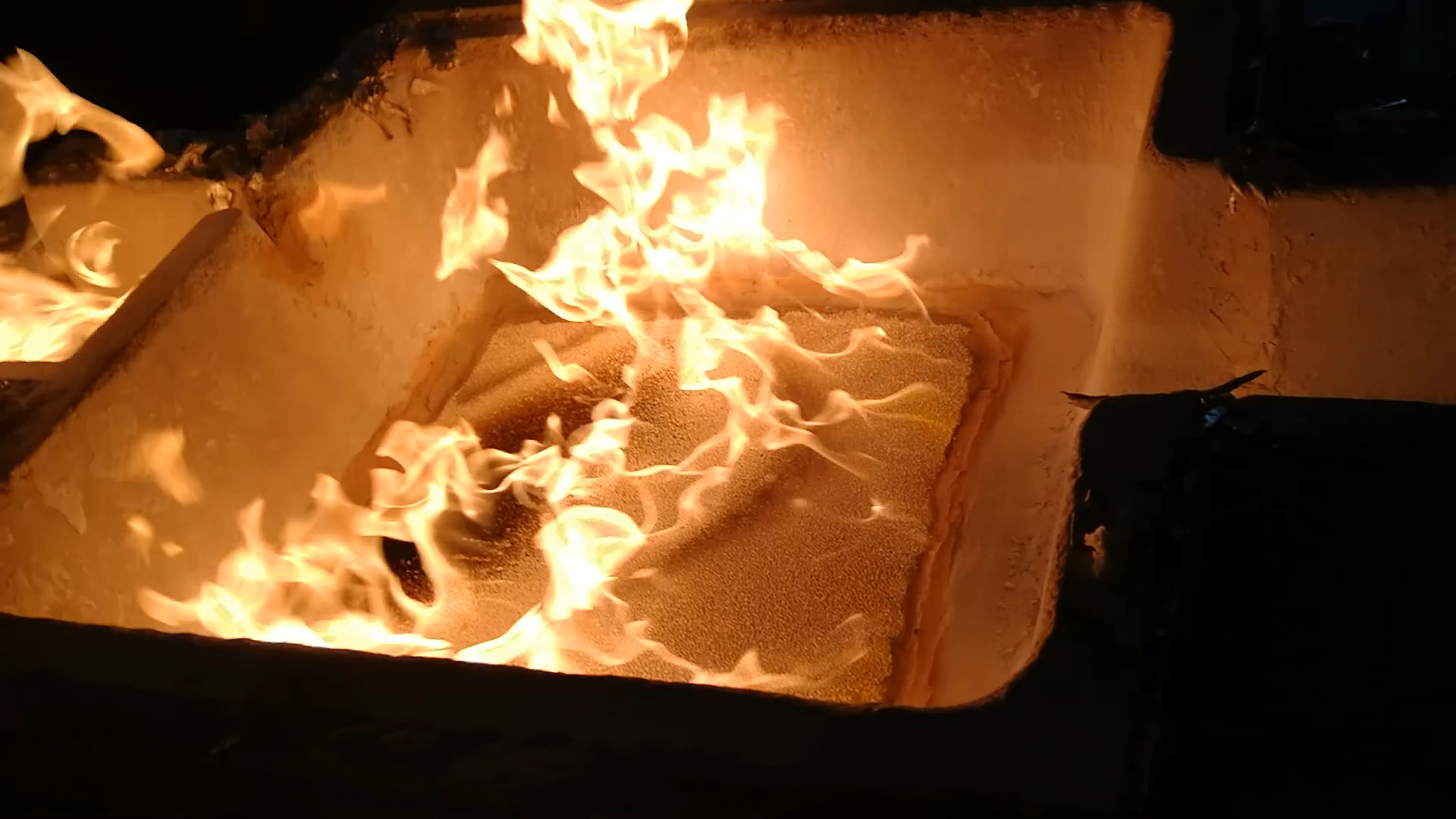

For Aluminium Casting Filtration

For Aluminium Casting Filtration For Foundries

Cost effective

Effectively remove non-metallic inclusions in metal castings

Reduced turbulence in the metal stream decreases oxide formation and mold erosion

Reduced casting scrap rates and customer returns

Improved as-cast surface finish

Improved casting machinability and reduced tool wear

Highly optimized runner system for improved yield

Wide range of standard sizes

Custom sizes and configurations available

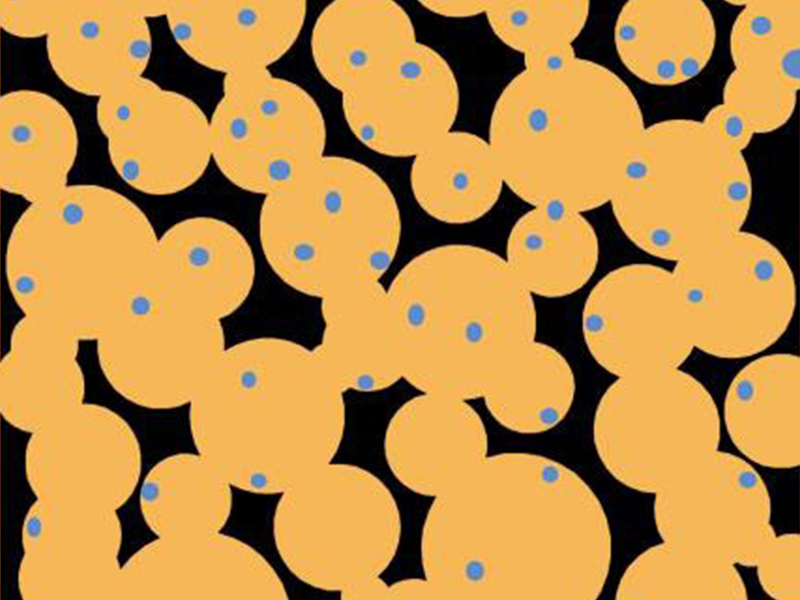

DIMENSIONAL AND STRUCTURAL CONSISTENCY

Unlike some filter types that have a random foam structure, the cellular structure of FlowRite filters is identical from one filter to the next, ensuring a high degree of consistency from pour to pour.

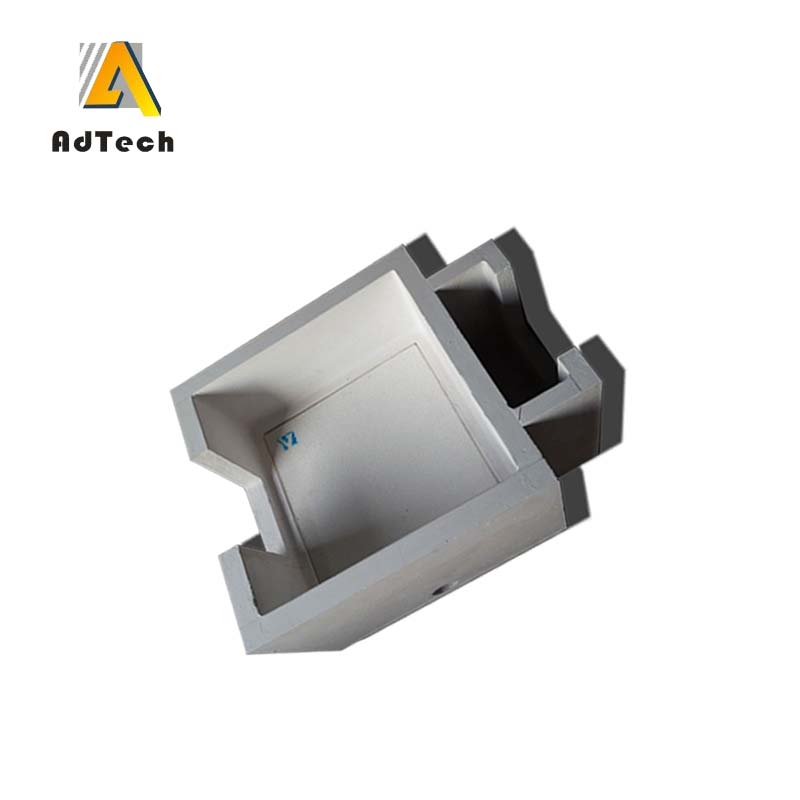

RAPID TOOLING

CoorsTek facilities are ISO certified and offer numerous capabilities to ensure your metal casting products are made to spec and delivered on time.

Excellent turn-around

Compaction tooling tailored to a customer’s specifications

Multi-axis CNC machinery, heat treating, wire and plunge EDM and other services

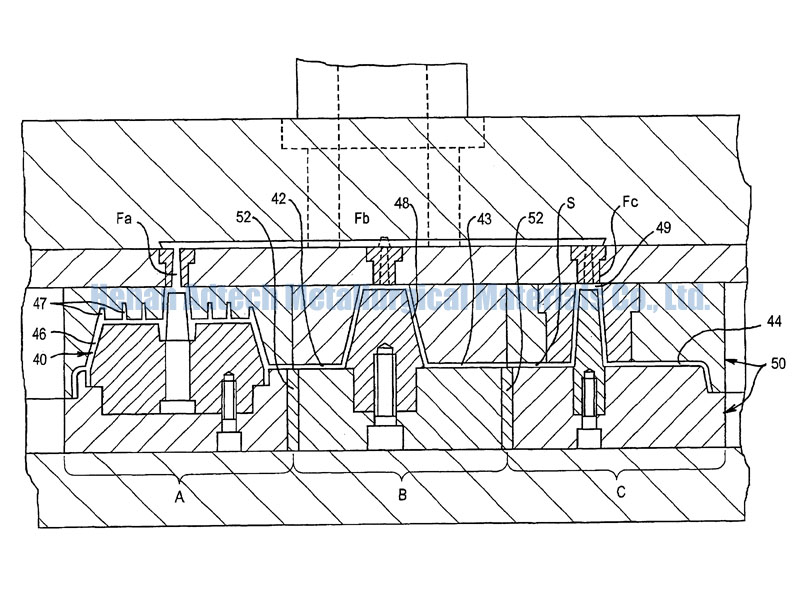

USAGE RECOMMENDATIONS

It is recommended that the runner’s system choke, not the filter, limit the flow rate of the molten metal. The total usable filter area should be larger than the system choke.

Minimum Recommended Ratios:

3 to 1 for gray iron

4 to 1 for aluminum and copper based alloys

5 to 1 for ductile iron

Note: Flow rates and total flow capacity vary with metallostatic head, metal temperature, metal cleanliness, and metal composition

For Aluminium Casting Filtration, AdTech China is professional. Please contact sales@adtechamm.com to buy Ceramic Filter For Foundry

Sorry, the comment form is closed at this time.