20 4月 Foundry Aluminium Degassing Process

Foundry Aluminium Degassing Process can meet the high technical performance requirements of aluminum alloy production.

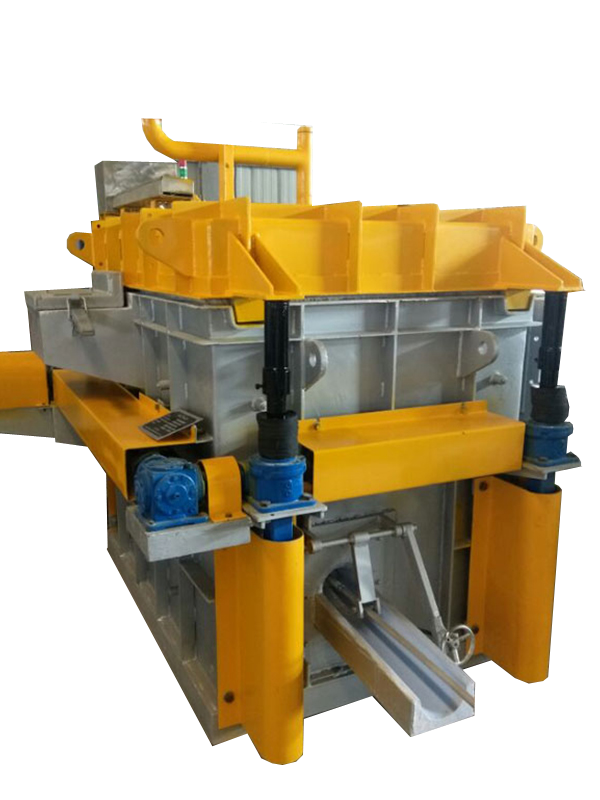

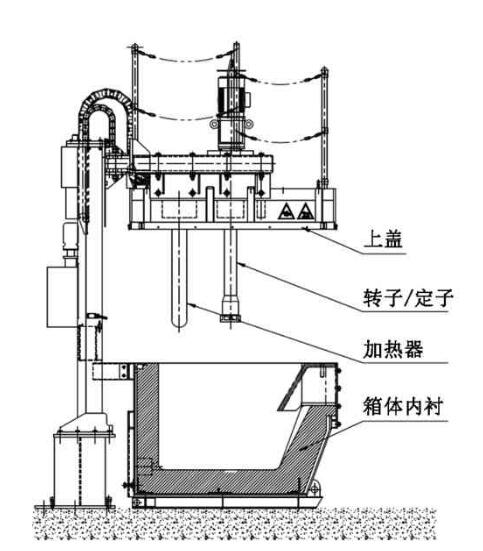

The aluminum degasser is located between the furnace and the casting machine, and its main function is to remove hydrogen and other residues.

The molten aluminum degassing equipment adopts new high-silicon melt material manufacturing technology. The main components include mechanical drive, box cover, rotor and heater.

The Foundry Aluminium Degassing Process can remove hydrogen (H) and slag in molten aluminum. It has the dual functions of processing and heating.

The Foundry Aluminium Degassing device uses a new type of high-silicon smelting material manufacturing technology. The CFF Casthouse can effectively filter and block the micron-level impurities in the molten aluminum.

Adopt new high-silicon smelting manufacturing technology. The high-precision online liquid aluminum purification device is mainly suitable for the aluminum alloy casting industry.

The gas in liquid aluminum is mainly hydrogen. Hydrogen is almost insoluble in solid aluminum, but very soluble in liquid aluminum.

Due to the difference in solubility, hydrogen tends to escape from the melt.

When the hydrogen pressure is greater than the surface tension and static pressure, bubbles will be formed, which in turn will form pinholes in the casting.

There is a strong interaction between inclusions and gas in aluminum alloy.

The hydrogen content in molten aluminum is greatly affected by inclusions.

In the case of the same hydrogen content, the higher the inclusion content, the higher the pinhole rate.

On the contrary, when the impurity content in the molten aluminum is very low, the hydrogen content is also very low. Therefore, it is equally important to remove impurities and hydrogen at the same time.

Molten aluminum degasser can achieve the purpose of purifying the aluminum alloy.

With the development of the automotive industry, more and more aluminum alloy castings are used, and the requirements for casting are becoming higher and higher.

In addition to ensuring the chemical composition, mechanical properties, and dimensional accuracy.

Aluminum alloy castings are not allowed to have casting defects, such as pores and slag holes.

Liquid aluminum purification treatment can improve the overall quality of aluminum alloys.

The refining effect has an important influence on the formation of holes and inclusions, and directly affects the physical and mechanical properties of aluminum alloy castings.

Therefore, we must pay attention to the gas and inclusions in the aluminum liquid. And it needs to remove the gas and inclusions in the aluminum liquid.

No Comments