20 4月 Foundry Degassing Process

Foundry Degassing Process: inert gas storage tank → online degassing device gas control cabinet → graphite rotor nozzle → processing aluminum alloy melt → purification and degassing treatment.

The working principle of rotary degassing is to increase the surface area of the inserted gas to contact the metal. The larger surface area increases the transfer rate from metal to inert gas.

In a certain volume of gas, the smaller the bubble size, the larger the surface area. Smaller bubbles have less interference on the surface of the melt, reducing the extra hydrogen absorption from the humid atmosphere.

Aluminum alloy is the most widely used non-ferrous metal structural material in the industry.

It is widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, chemical industry and other industries. With the rapid development of industrial economy, the demand for aluminum alloy is also increasing.

The degassing process is necessary to remove the dissolved hydrogen and non-metallic inclusions in the molten metal before the casting reaches the best quality.

The hydrogen dissolved in the molten substance diffuses into the rising flux bubbles and is transported to the surface of the molten substance.

Foundry Degassing Process principle

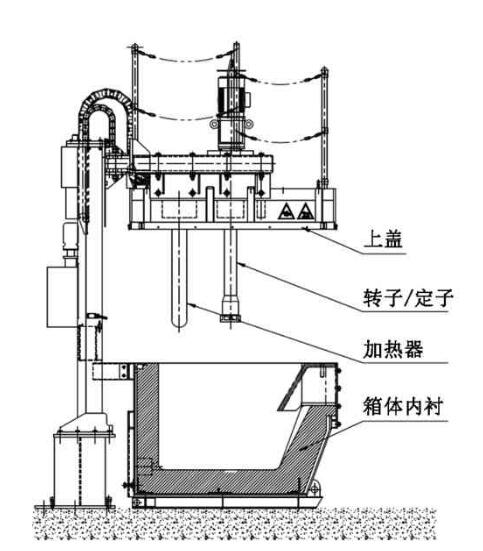

A degassing device is provided between the holding furnace and the casting machine.

In the degassing treatment tank, the nitrogen blown into the aluminum alloy melt is crushed by the rotating graphite rotor to form a large number of diffusion bubbles, so that the aluminum alloy liquid and the nitrogen are fully contacted in the treatment tank.

According to the principle of pressure difference and surface adsorption, the bubbles in the melt absorb hydrogen in the melt and adsorb oxidized slag (large ones rely on collision, small ones rely on radial interception). Scum is formed on the surface of the melt. The aluminum alloy melt flows from the outlet of the Aluminum degassing device (located at the lower part of the scum) to the casting machine.

The aluminum alloy liquid continuously enters the degassing device, and the nitrogen is continuously blown in. Through the degassing process, the purpose of purifying the aluminum alloy liquid is achieved.

The processing box of the degassing device includes two inner chambers, a clean room and a heating and holding room.

The middle is separated by SiC separators.

After degassing and removing slag in the clean room, the aluminum alloy liquid flows into the heat preservation room from below the partition. A U-shaped silicon carbon jacket and a silicon carbide protective tube immersed in the aluminum alloy liquid are used to heat the heat preservation chamber.

The box shell is made of 10mm steel plate, and the inner lining is made of refractory materials.

The heater is convenient to directly conduct and carry the submerged flow of the processed aluminum alloy liquid.

According to our company’s suggestion, there is a slag removal door at the lower part of the two side walls of the box.

The slag removal in the cavity is completed without activating the cover, which prolongs the service life of the inner cavity of the box, and at the same time improves the heat insulation performance of the box and increases the heat loss.

The reduction and thermal compensation of the heating furnace fully meet the temperature requirements of the production process; the box has good airtightness, which can prevent the air from entering the box and the secondary pollution of the aluminum alloy liquid.

Equipped with a hydraulic tipping device, it can be completely discharged after the casting work is completed or after changing the alloy, and the box can be completely emptied. The heater does not need to be energized for a long time to maintain the heat, and the power consumption can be relatively reduced.

No Comments