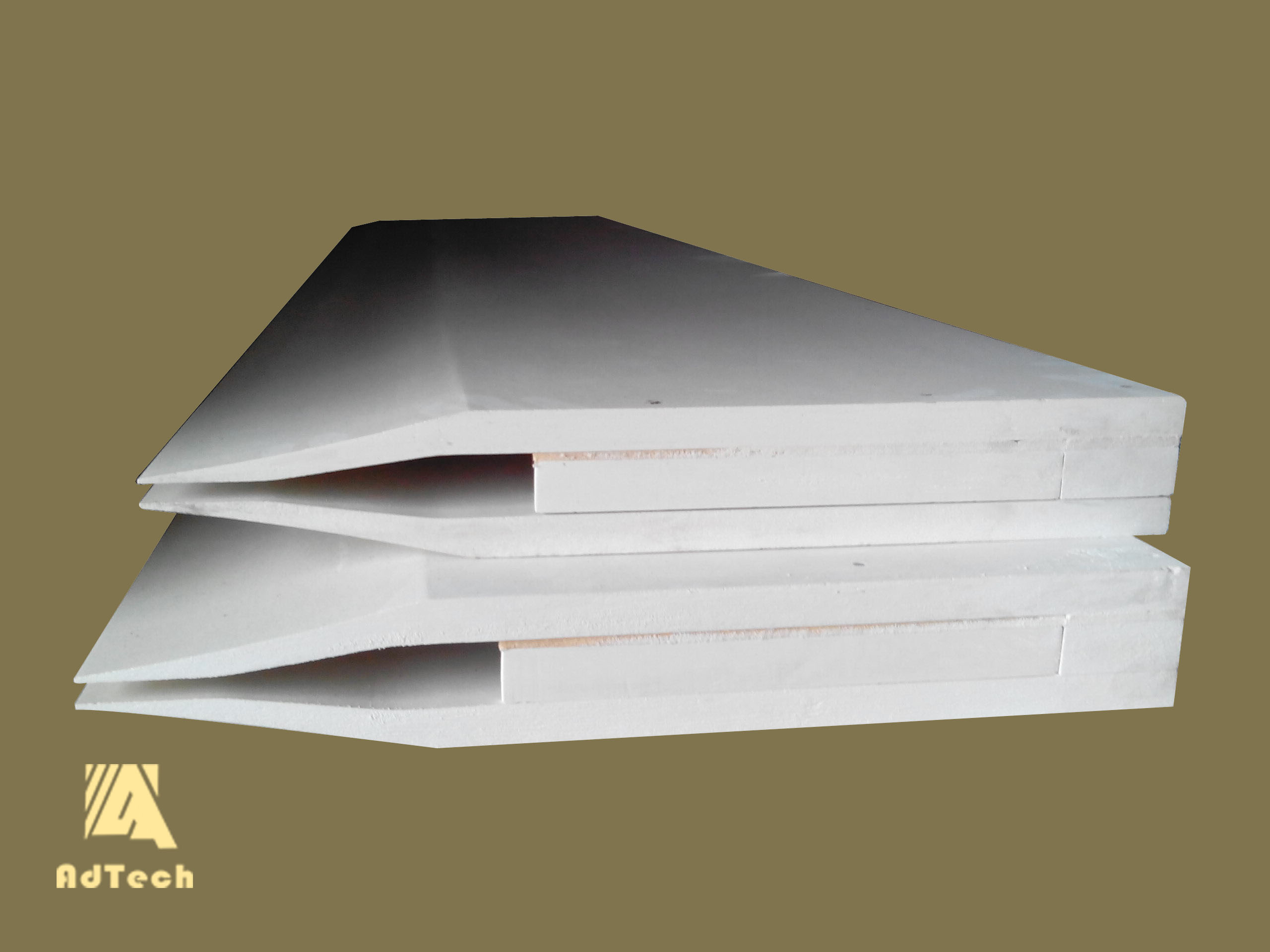

07 5月 Foundry Feed Tip Cavity

Foundry Feed Tip Cavity has a great influence on strip quality. In the double-roll aluminum casting and rolling process. A suitable Feed Tip cavity structure is of great significance for achieving stable, efficient, fast and continuous casting and rolling production.

Foundry Feed Tip Cavity is a key component of the aluminum strip continuous casting and rolling mill, and its quality directly affects the quality of the strip and the yield of production. The casting nozzle material can be divided into multiple models according to the performance and needs of different casting and rolling machines.

The high-silicon-oxygen Feed Tip is made by mixing high-silicon-oxygen and a variety of other materials. It has the advantages of good elasticity, no deformation, and long use time.

Its special process can effectively prevent molten aluminum from eroding the casting nozzle and avoid carbonization.

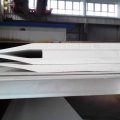

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flocculent tissue.

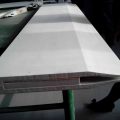

The coating on the working surface is uniform and smooth to prevent the occurrence of granular cracks and coating shedding, and provide a guarantee for high-quality cast-rolled plates.

The surface is specially treated with aluminum titanate coating, and its special process can effectively prevent the aluminum liquid from eroding the casting nozzle and avoid carbonization.

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flocculent tissue.

The coating on the working surface is uniform and smooth to prevent the occurrence of granular cracks and coating shedding. It provides protection for high-quality cast-rolled plates. Various models and flow-supply casting nozzles can be made according to customer requirements.

The internal structure is designed with reasonable symmetrical flow channels to meet the requirements of liquid aluminum fluid mechanics

1. Excellent insulation performance

2. High flexural and compressive strength

3. Excellent thermal shock resistance

4. The surface is smooth and non-stick aluminum

5. Good insulation performance

No Comments