05 8月 Foundry Foam Filters

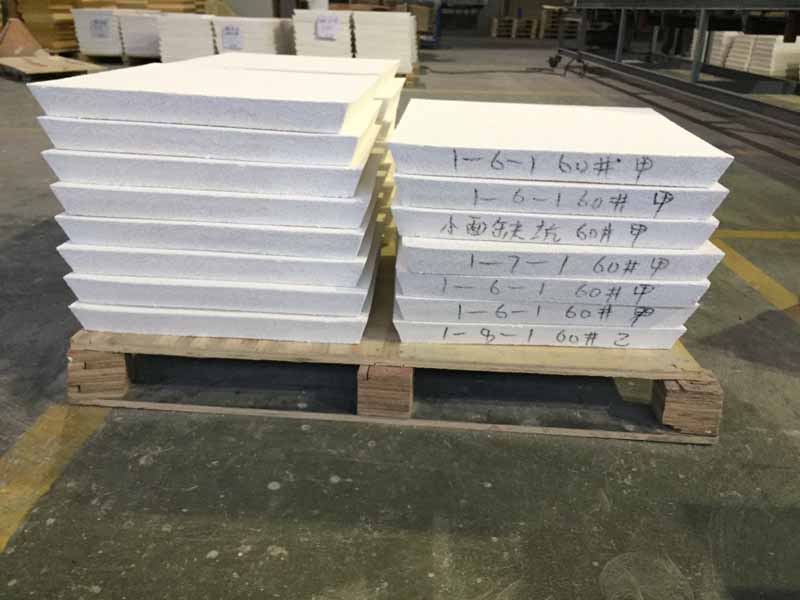

Foundry Foam Filters

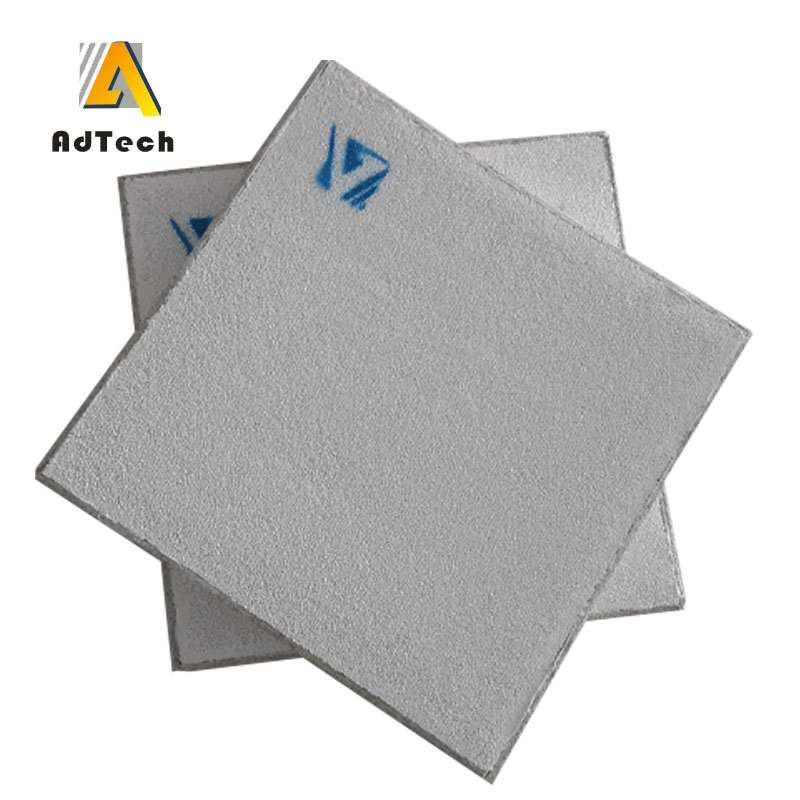

Foundry Foam Filters can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield.

It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

Foundry Foam Filters Production Process

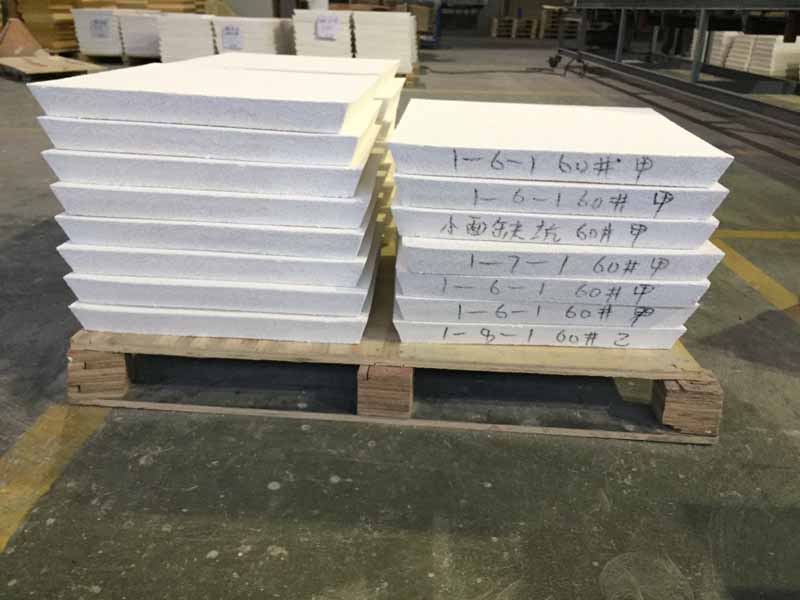

The Ceramic Foam Filter uses a three-dimensional network structure and an organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropic properties, and adopting a special roll extrusion process to uniformly apply the ceramic slurry to the skeleton of the carrier.

Then, it is dried and solidified and then fired at a high temperature.

Porous Ceramic Foam Filter Foam Ceramic Filters for Aluminum Alloys Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Porous Ceramic Foam Filter uses polyurethane foam as a carrier, immersing it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruding excess coating to uniformly apply the ceramic coating to the carrier.

The skeleton becomes a green body, and the green body is dried and fired at a high temperature.

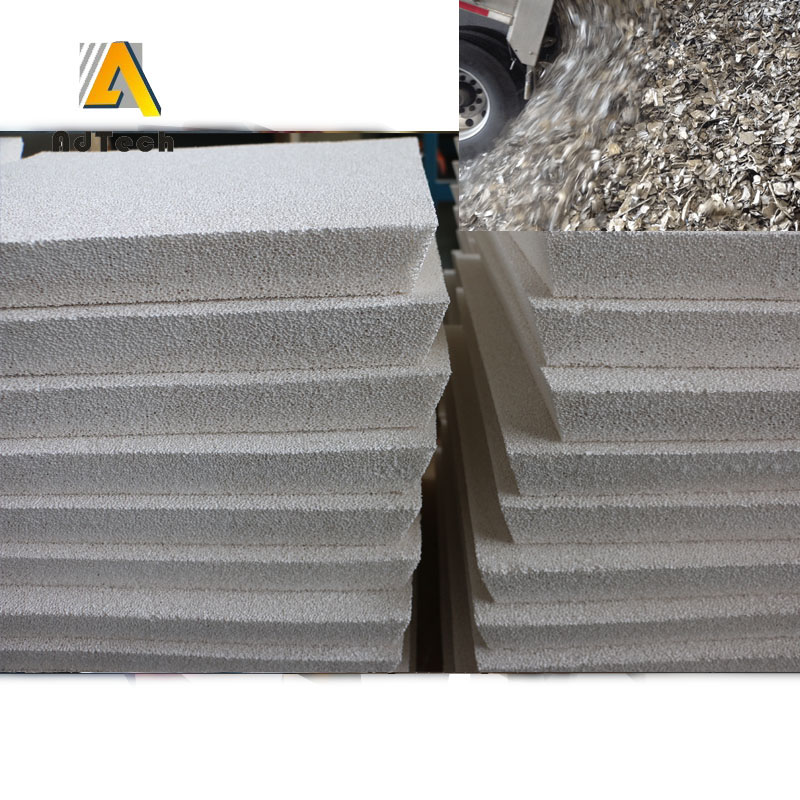

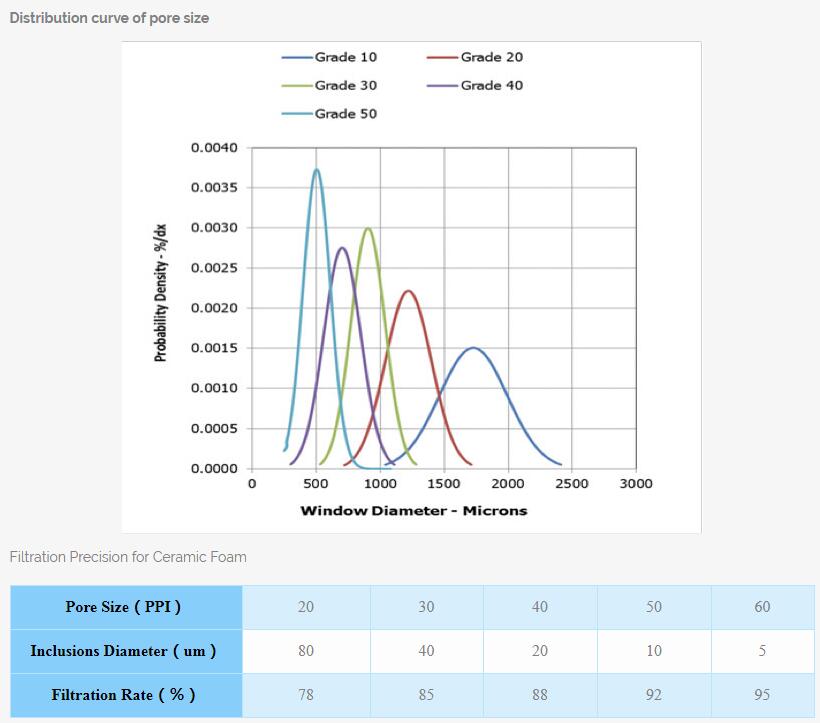

Foundry Foam Filters Pore uniformity

Pore uniformity is used to describe the difference between the number of actual holes per 25.4 mm length in the filter plate product and the number of theoretically required holes.

The smaller the gap, the better the product quality, and the gap is too large, which will result in the ability of the filter plate product to reduce the impurity retention or the slow filtration rate of the melt, which can not meet the individual requirements of the user’s production.

The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The uniformity of the pores of the foam is good, and the uniformity of the pores of the filter plate is good, so the selection of the foam is extremely important.

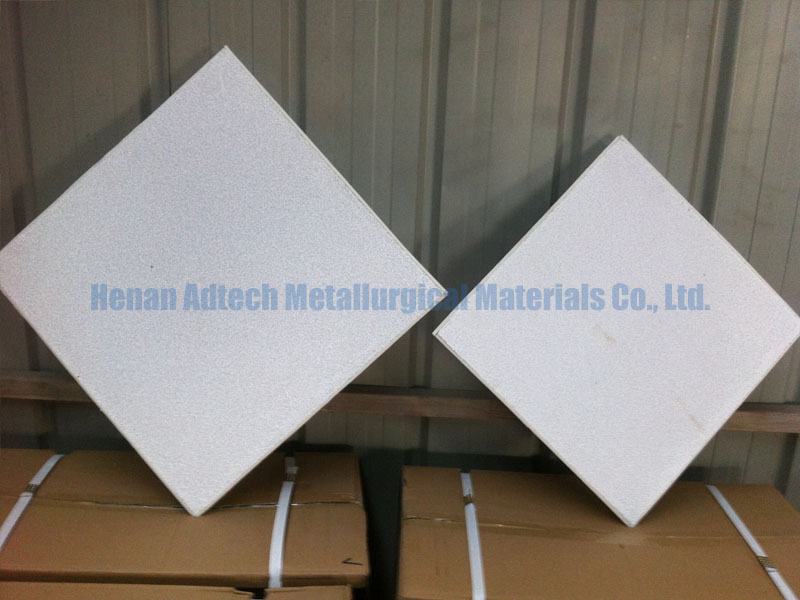

10Ppi,20Ppi,30Ppi,40Ppi,50Ppi 60Ppi Ceramic Foam Filter

The filter 10 PPI Foundry Foam Filters means that there are 10 honeycomb holes on one square inch of the filter sponge.

The 30PPI filter sponge has 30 small holes in one square inch. The larger the value, the smaller the hole.

Generally, 15-20 PPI means a large hole, 25-30 PPI is a medium hole, and 35 PPI or more is a small hole.

10-50Ppi Alumina Ceramic Foam Filter has a void ratio of over 97% and an open cell ratio of 99%. It has good gas permeability and high mechanical strength. Therefore, it has the characteristics of low flow resistance and high filtration efficiency.

Sorry, the comment form is closed at this time.