12 10月 Foundry Single Rotor Deaerator

Foundry Single Rotor Deaerator

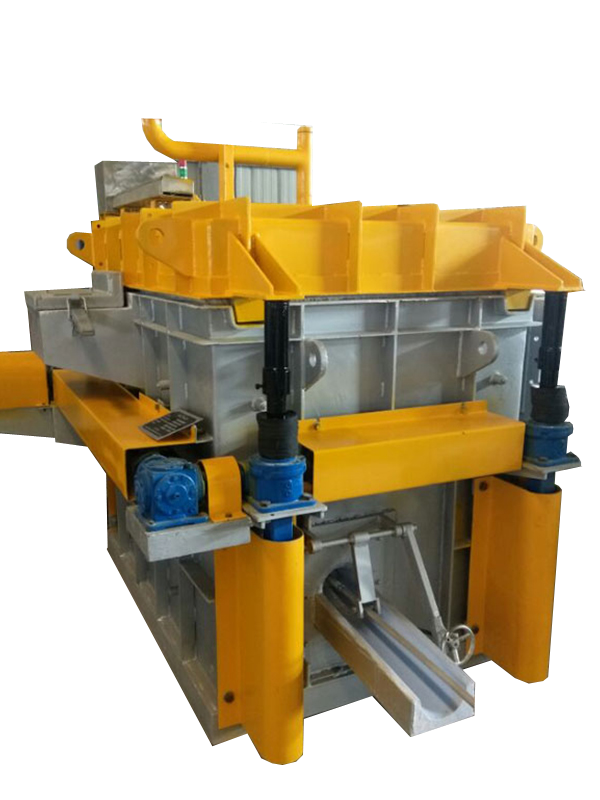

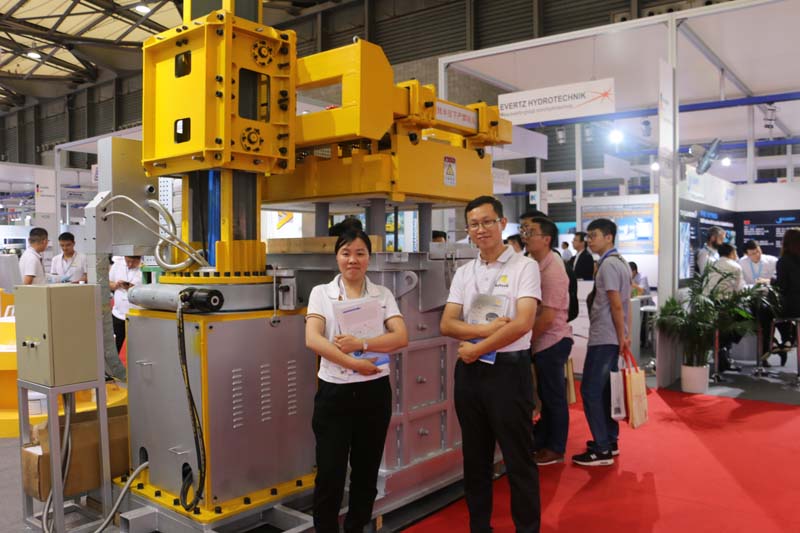

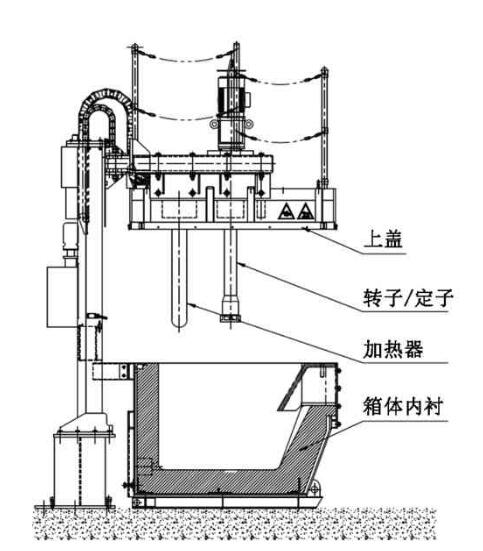

The single rotor deaerator is a pollution-free green aluminum liquid purification treatment device. The principle is: the aluminum liquid is stirred by a controlled rotating graphite shaft and a rotor, and the metered inert gas is pressed into the aluminum liquid through the rotor and broken up. The fine bubbles are evenly dispersed in the liquid metal, and the gas partial pressure of the bubbles is zero. Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, and inertness of useless hydrogen and some non-metallic inclusions adheres. The gas bubbles float up to the liquid surface, and then the desulfurization and the removal of the oxide inclusions are achieved by the slag. The degassing principle is also recognized, the efficiency is high, the production process is not affected, and the aluminum liquid can be raised in a short time. Purity, reduce scrap rate, improve production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products, which is not achieved by traditional degassing methods.

High degassing efficiency: The single rotor deaerator adopts a compact furnace design, and uses a single rotor to degas in the degassing box to form convection in the tank, so that small bubbles can be fully diffused in the aluminum liquid. The contact surface of the bubble and the aluminum liquid is adopted; at the same time, the sealed design is adopted, which prevents the external air from entering and causes secondary pollution, thereby improving the degassing efficiency of the device.

Precise control: single rotor deaerator workstation degassing method, aluminum liquid can maintain temperature by electric heating at working gap, heating system adopts immersion heating device, heating efficiency is high, silicon carbon rod heating element is used, thyristor temperature control The temperature control precision is high and the use is convenient.

Easy to operate: It adopts one-button switching, which is simple and easy to use, reduces the complexity of the system and reduces the maintenance cost of the equipment. At the same time, the user’s requirements for casting quality are considered in the design of the equipment, and the refining gas flow and rotor speed are adjustable. . Convenient for equipment maintenance and rotor replacement, the rotating nozzle part and the heater part can be lifted separately, and the upper cover can be lifted and horizontally rotated to maximize maintenance and maintenance operations. ??? Operational safety: The equipment has an interlocking mechanism to avoid injury caused by misoperation.

The principle of the single-rotor degasser is that the rotating rotor in operation breaks the inert gas (argon or nitrogen) blown into the aluminum water into a large amount of dispersed bubbles and disperses them in the aluminum liquid; the bubbles are in the molten liquid. Gas partial pressure difference and surface adsorption principle, absorb hydrogen in the melt, adsorb oxidation slag, and be taken out of the surface of the melt as the bubble rises, so that the melt can be purified; due to the fine dispersion of the bubbles, evenly mixed with the rotating melt And then rotates in a spiral shape and slowly rises, and does not form a continuous airflow generated when it comes into contact with the molten metal, thereby significantly improving the purification effect.

No Comments