30 10月 High Aluminum Launder

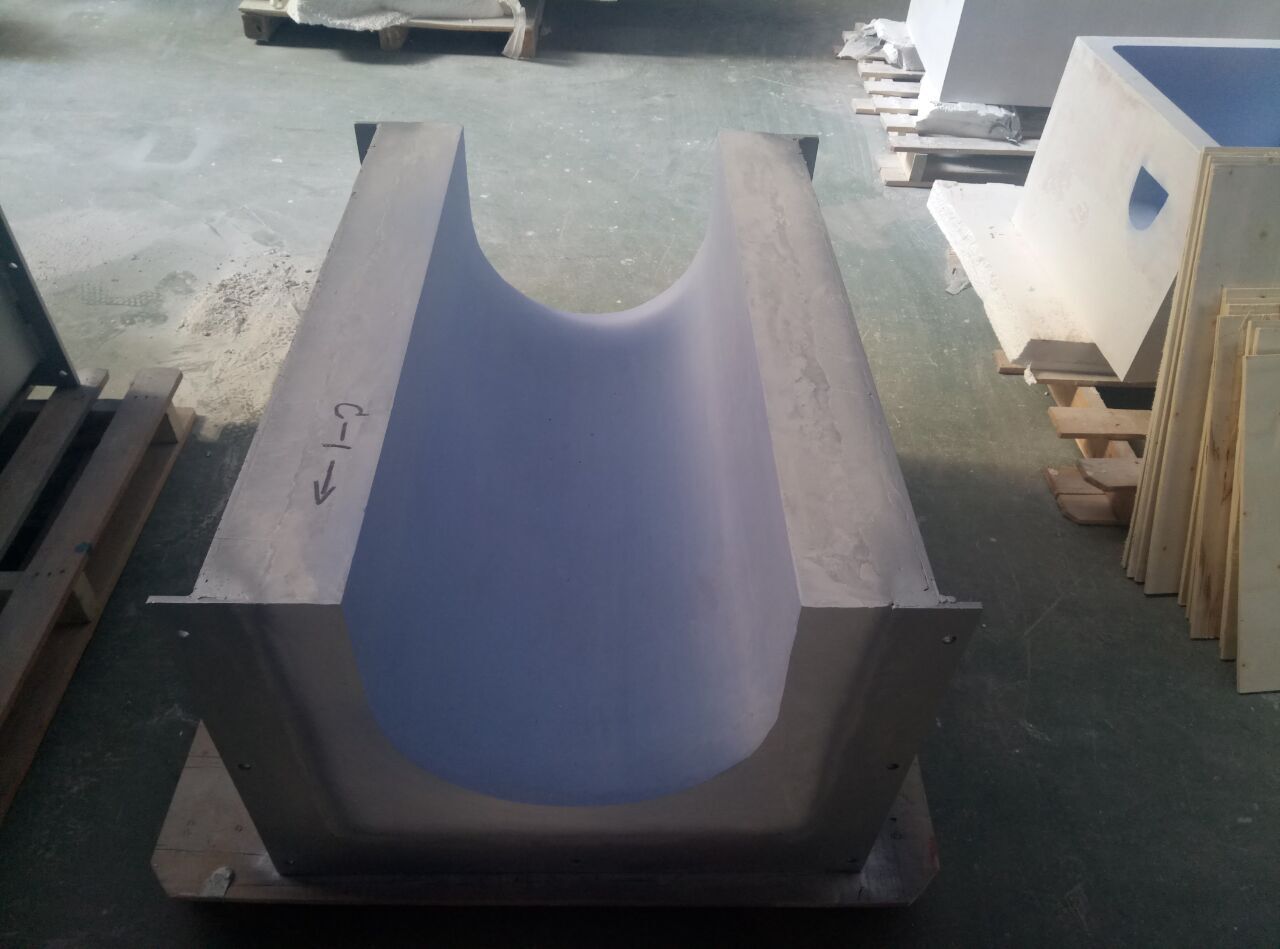

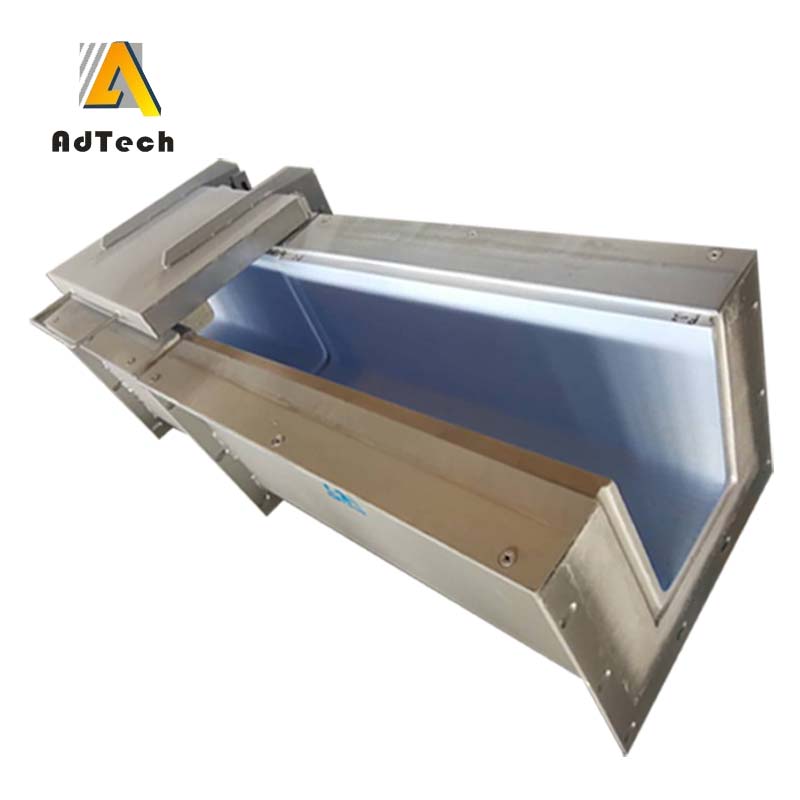

High Aluminum Launder

AdTech’s High Aluminum Launder industry has accumulated many years of research and accumulation.

Based on the survey results of key enterprises in the industry and consulting experts, the system has summarized the application strategies of high-alloy DC tank products, including new product development strategies and optimized combination strategies. , life cycle strategy, marketing strategy, brand strategy, etc., have very important reference value for enterprises intending to enter the aluminum liquid flow tank industry and the industry that has entered the aluminum liquid flow tank industry.

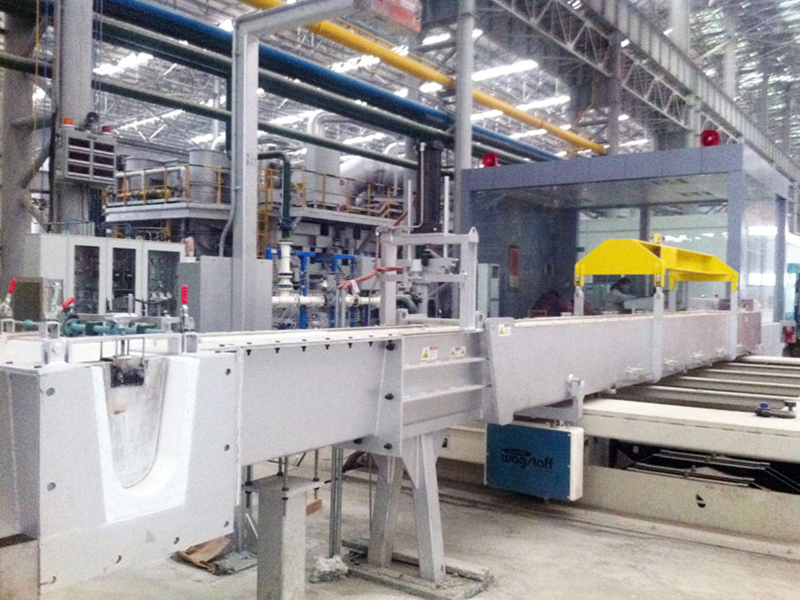

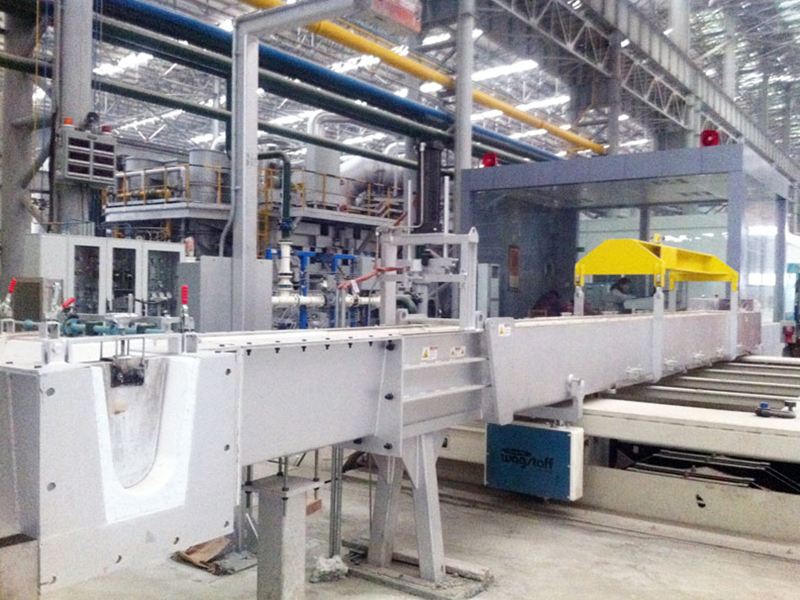

High Aluminum Launder is one of the basic equipments for aluminum alloy casting.

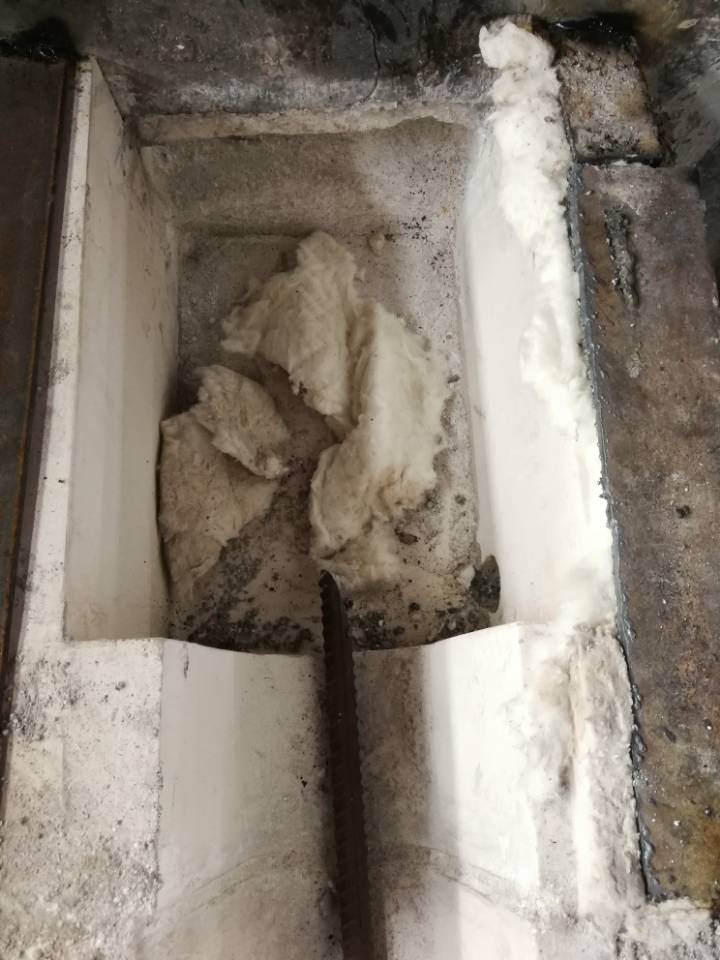

Its main function is to divert the aluminum liquid from the furnace to the casting machine. The working area was originally built using a flow tank for the traditional high-temperature resistant castable. In the process of use, the surface is easy to stick aluminum, the working time of the operator is up to 30 minutes when cleaning the launder, and the casting material is easily damaged, so that the high-temperature aluminum liquid penetrates into the casting material, causing the shell steel plate to gradually deform, and the flow tank is 4 months. It can’t be used normally. In addition, each pair of launders is maintained once, the castables need to be removed, and the shell steel plates are calibrated and rebuilt, and the maintenance process is labor-intensive.

In response to this problem, the operation area is retrofitted to the High Aluminum Launder after referring to the use condition of the same industry. The new flow tank after the transformation has high overall strength and large unit density. The surface of the high-alloy DC tank is coated with The high-temperature refractory coating is not easy to stick to aluminum, and the internal slag is easy to clean. Under high temperature conditions, there is no damage or cracking in two years, and there is no leakage of aluminum at the flow channel interface and the bottom, which eliminates the safety hazard of aluminum leakage in the flow cell, and shuts down the flow cell. The time reduction of 20 minutes not only reduces the labor intensity of the general aluminum work, but also saves a lot of maintenance costs compared to the traditional use of the trough for two years.

No Comments