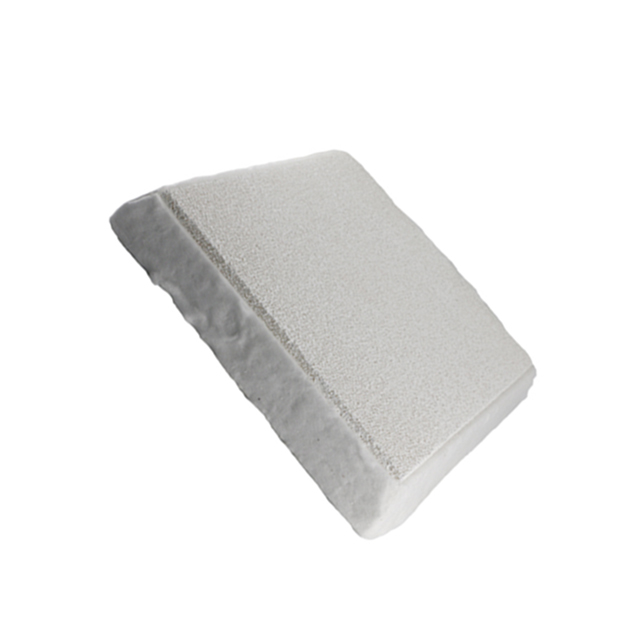

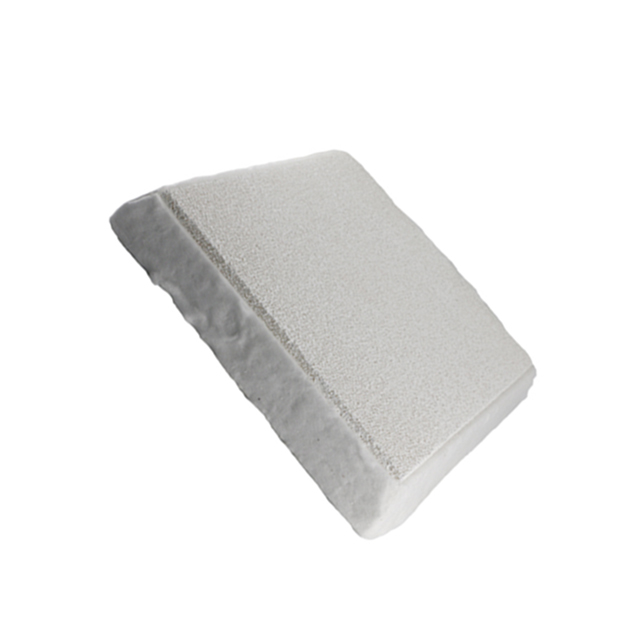

18 11月 High Ceramic Foam Filter

High Ceramic Foam Filter is mainly made of materials with excellent strength and high temperature impact resistance and chemical corrosion.

It can withstand high temperatures up to about 1760 °C.

Therefore, they are suitable for the porcelain filter to significantly improve the quality of cast iron parts and reduce the scrap rate. It can also be used in the continuous casting and rolling process, and can be manufactured to all standard sizes and different thicknesses. There are three kinds of silicon, zirconia and alumina.

Non-metallic inclusions in castings are the most important cause of casting defects, which affect the surface finish, mechanical and processing properties of the casting and result in increased reject rates.

The bubble is mixed and the turbulence is reduced to achieve a fast and stable metal liquid filling flow rate, and thus the casting quality is improved.

Significant filtration of all steel grades, including carbon steel, stainless steel, cobalt-based nickel

1. Made of pure zirconia material, the temperature can reach 1760 °C, which is not sensitive to the temperature change of different steel castings.

Excellent raw materials and advanced production technology ensure that the filtration meets the requirements of manual molding and more efficient mechanized production lines, and ensures that the quality of the foundry products meets the international quality standards.

2, alumina foam ceramic filter, suitable for temperature 1250 ° C, suitable for filtration of aluminum and alloy solutions.

Widely used in ordinary sand casting such as tidal casting and long-term.

The alumina foam ceramic filter product effectively removes the solid inclusions in the molten metal. The product has a fine pore size of 10 ppi to 70 ppi, and the specification and model can be used according to the requirements of the user.

Sorry, the comment form is closed at this time.