05 11月 Hindalco Industries Limited Foundry Launder

Hindalco Industries Limited Foundry Launder

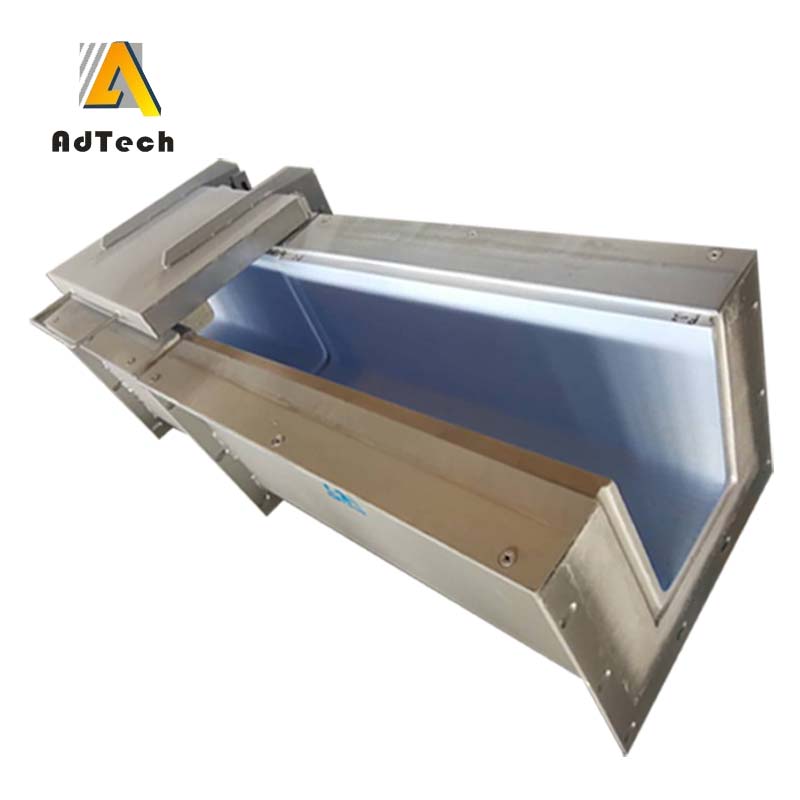

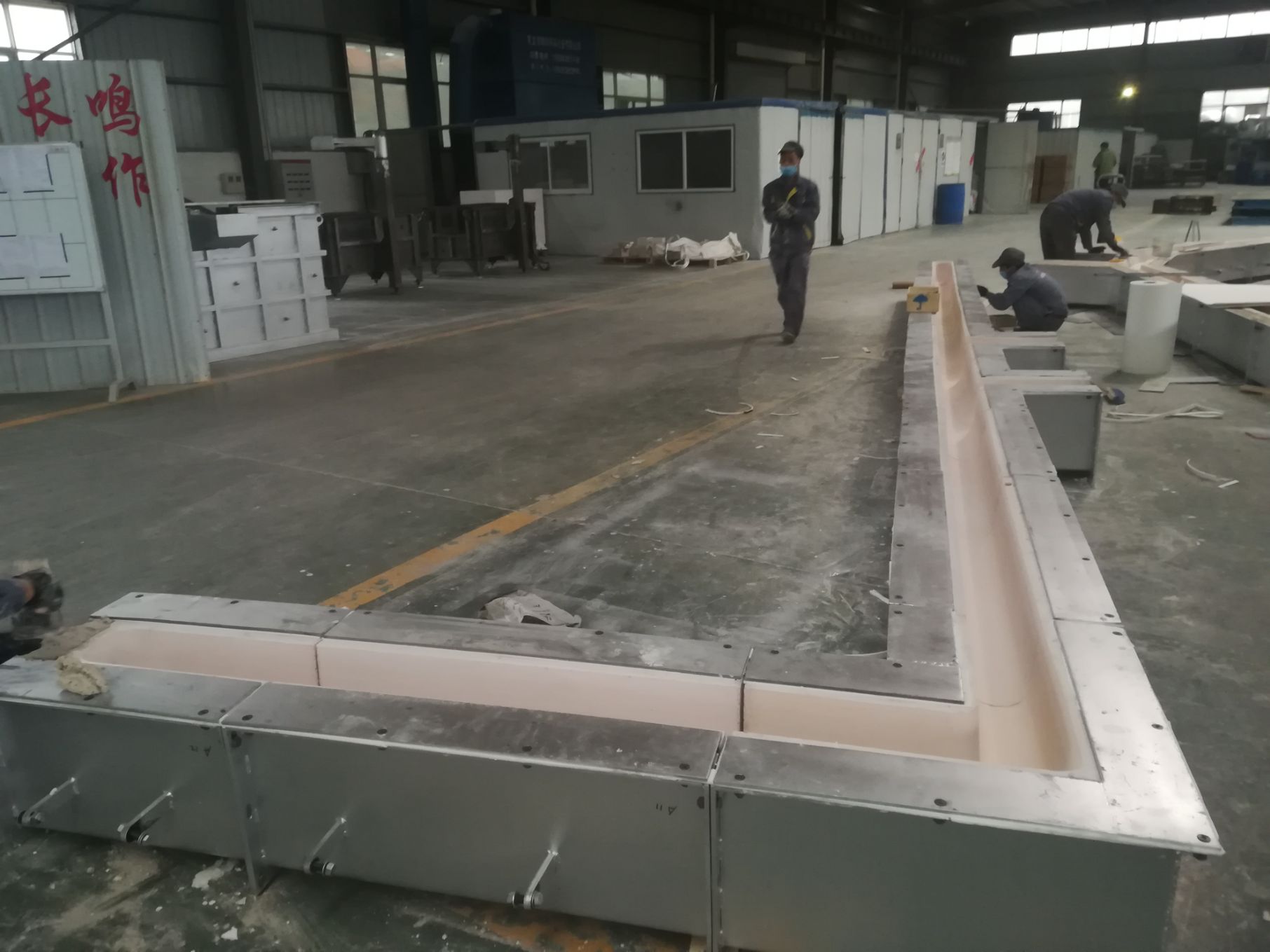

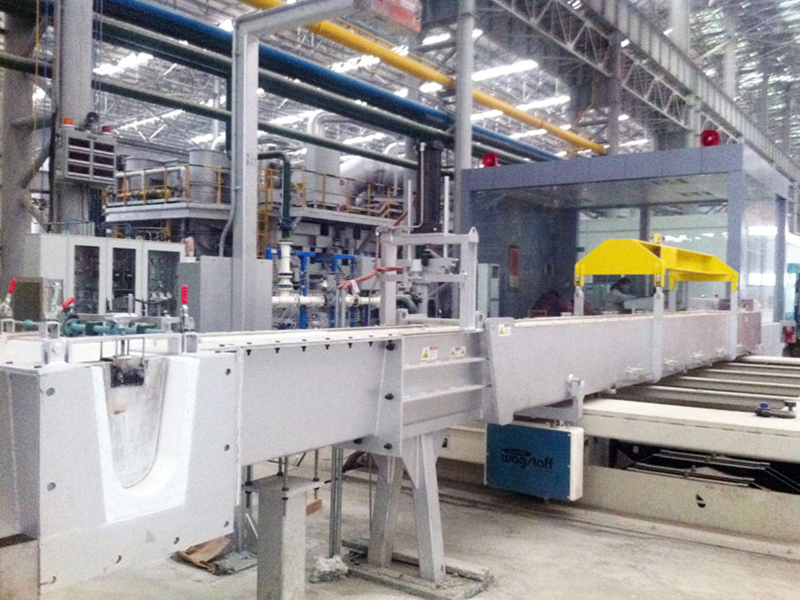

Hindalco Industries Limited Foundry launder is one of the basic equipment for aluminum alloy casting. Its main function is to divert the aluminum liquid from the mixing furnace to the casting machine. Hindalco Industries Limited Foundry launder is built for the traditional high temperature resistant castable. During the use process, the surface is easy to stick aluminum, and the operator can clean the launder for up to 30 minutes, and it is easy to cause the castable to be damaged, so that the high-temperature aluminum liquid penetrates into the castable material, causing the shell steel plate to gradually deform. After 4 months, the runner is deformed. Not working properly. In addition, each pair of launders is maintained once, the castables need to be removed, and the shell steel plates are calibrated and rebuilt, and the maintenance process is labor-intensive.

Hindalco Industries Limited Foundry launder has developed with the changes of the market. The management and management of the company has changed from a single target development to a systematic and scientific management. How to understand the development and market of the platter industry from a professional perspective? The transformation, how to use scientific methods to effectively manage all aspects of the enterprise, will become the primary issue for the future survival and development of the enterprise.

Hindalco Industries Limited Foundry launder advantages:

1. Good thermal insulation performance (temperature drop is within 1 °C per meter), low density, good non-stick aluminum performance, good casting and rolling operation;

2, the use of high silicon molten material integral molding, high dimensional accuracy;

3, can be repeated or used multiple times, the surface is smooth.

The refractory material used in the type of Adtech Launder sales@adtechamm.com is an unshaped refractory material. He does not have specific dimensional specifications. It only requires the use of materials and environment. The high temperature environment has acid corrosion, alkaline corrosion, abrasion resistance and erosion resistance. In the working ring conditions, the appropriate refractory castable should be selected according to the environment and nature of the above.

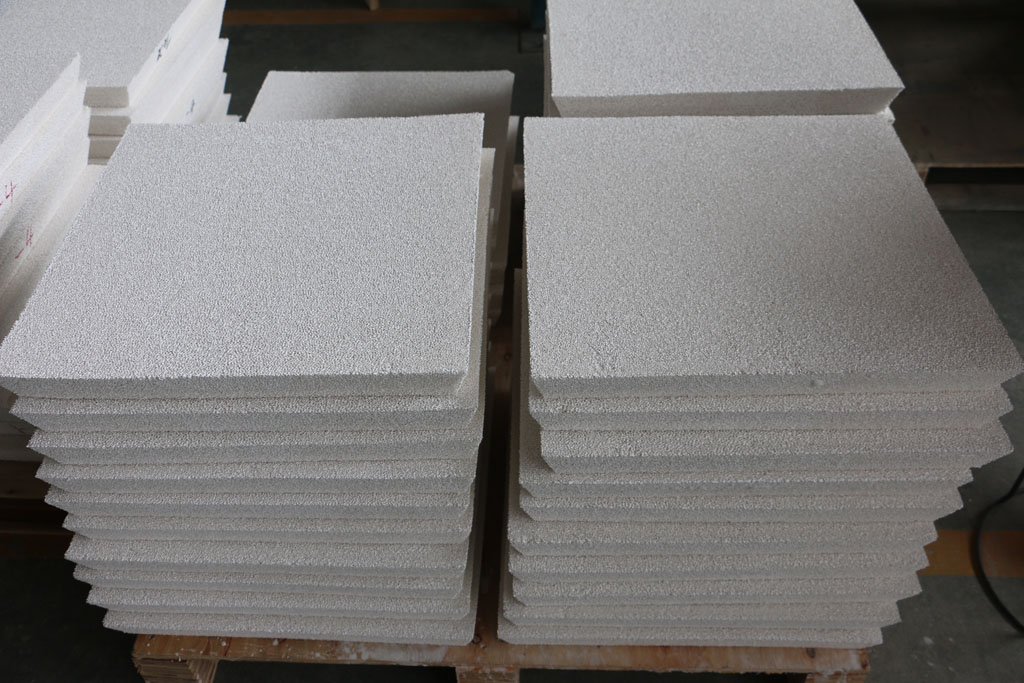

The material used for the type of trough: a new type of sheet made of siliceous and calcareous materials, which is made by pulping, forming, steaming, drying, sanding and post-processing, etc. A non-asbestos high-performance thermal insulation material with low bulk density, high strength, low thermal conductivity, high temperature resistance, corrosion resistance, energy cutting, energy sawing, etc., widely used in electric power, metallurgy, petrochemical, construction, shipbuilding, cement, etc. Thermal insulation of boilers and industrial furnaces in the industry.

No Comments