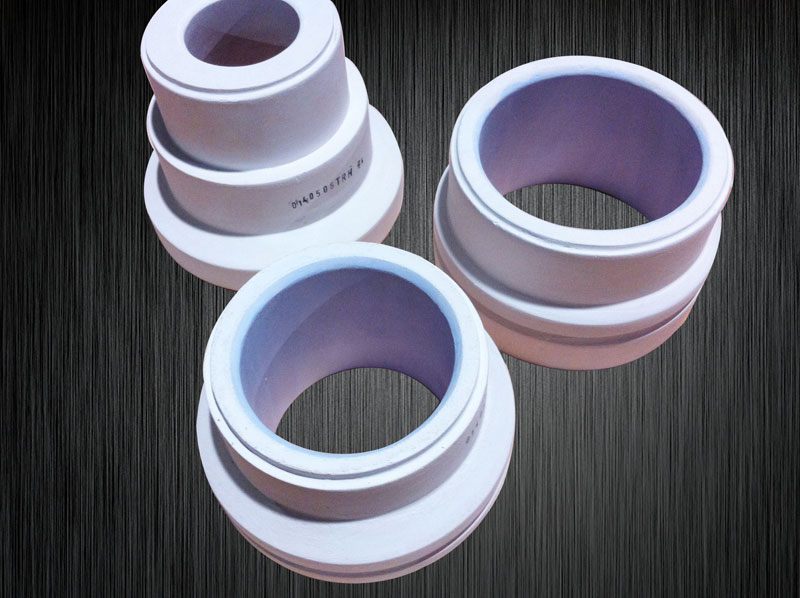

15 3月 Hop top Casting Sprue Bush

Hop top Casting Sprue Bush is widely used in the hot top casting of aluminum and aluminum alloys. It is used in conjunction with the casting table for precision casting. During casting, the distribution plate aluminum liquid is connected to the mold mold to form. Has 2. High density and hardness, good thermal shock and impact resistance. High precision, long service life and low maintenance cost.

Sprue Bush specifications

3.5in 3in 4in 4.5in 5in 5.5in 6in 7in 8in 9in 10in 12in 14in, or as customer’s requirement

Hot top casting refers to a casting form in which there is a section with good heat preservation performance on the top of the crystallizer. The fundamental purpose of hot top casting is to slow down the primary cooling of the upper part of the mold.

Hot-top casting is not only beneficial to improve the surface quality of the ingot, but also to the bottom-up directional solidification and supplementary shrinkage of the ingot. If the filter plate is added in the hot top section at the same time, it can prevent the molten slag from entering the ingot .

The key to hot top casting technology lies in the hot top design of the mold.

There are many types of hot-top casting molds.

The initial design of the hot-top crystallizer is to connect an additional asbestos lining with heat insulation and heat preservation functions above the crystallizer.

Asbestos is a kind of heat-resistant heat-insulating material, which can effectively heat the aluminum melt by using it as a hot top lining.

The difference between the hot top electromagnetic casting method and the ordinary electromagnetic casting method is that it adopts a special shielding cover structure and uses refractory materials to make the top melt of the hot top constrained liquid column, that is, the hot top has the function of a shielding cover.

Hot top electromagnetic casting technology has the following advantages

(1) Compared with electromagnetic casting technology, the hot top has the effect of restricting the forming of part of the liquid column. The control of the position of the metal liquid level is easier in comparison and is conducive to the stability of the liquid column height.

(2) As the hot top section gradually increases from bottom to top, the influence of the increase or decrease in the amount of molten metal during the casting process on the height of the liquid column is significantly weakened, thereby enhancing the stability of the height of the liquid column and the size of the ingot.

(3) The hot top facilitates the pouring of molten metal and weakens the impact of pouring on the molten metal column.

(4) Since the liquid column at the liquid-solid interface is still constrained into a semi-suspended state by electromagnetic force, the solidification of the side surface of the ingot in the free surface state is ensured, and the electromagnetic stirring effect in the liquid cavity is not weakened, which inherits the electromagnetic casting. The ingot has the advantages of bright surface and dense internal organization. The hot top electromagnetic casting technology not only gives full play to the advantages of ordinary electromagnetic casting and electromagnetic continuous casting, but also enhances the operability of the system. Its magnetic field strength and electromagnetic pressure distribution are reasonable, which can effectively control the ingot inclusions and improve the surface and interior of the ingot quality.

Hop top Casting Sprue Bush product advantages

1. Good non-lubricity, smooth glazed surface, high geometric processing accuracy and low maintenance cost.

2. There is no delamination and peeling phenomenon, which effectively reduces the pollution of molten aluminum, and achieves pollution-free precision aluminum casting.

3. Erosion resistance, good thermal shock resistance, and improved corrosion resistance to molten metal.

4. It is better to use with Boron Nitride (BN) paint, with a normal life span of 450-800 castings, which can save energy and reduce consumption.

No Comments