20 11月 Impurity Separation Ring

Impurity Separation Ring

Adtech has a team of experienced professionals who have been engaged in aluminum and aluminum alloy melting.

Casting production technology research and melting and casting production technology operations, and have strong new product research and development capabilities. The company has a special technical information platform to be able to keep abreast of cutting-edge aluminum and aluminum alloy casting production technology and advanced materials and advanced equipment.

Adtech has been committed to the research of advanced casting technology and mold technology, combined with the characteristics of traditional Chinese casting methods, developed a slag blocking device for the aluminum industry belonging to its own proprietary brand. The company has a casting team consisting of aluminum and aluminum alloy casting engineers and casting technicians. It is responsible for the research and development of the aluminum industry slag blocking device, aluminum liquid degassing box, ceramic filter plate, plug and other products, and can provide customers with Solutions are provided at every step of the production process from the melting furnace to the end of the casting process.

With the increase in the demand for aluminum production in the aluminum industry, the quality of aluminum products in the aluminum industry is relatively high. At the time, I have studied the new product aluminum industry slag. The device also occupies an important position in the aluminum industry. This product belongs to the combined use of aluminum moisture flow. It is very common in the manufacturing process of aluminum ingot factory and aluminum wheel hub, and can effectively remove the quality of impurities to ensure the quality of products. It is the key to achieving today’s demanding quality standards for DC aluminum and aluminum alloy slab casting.

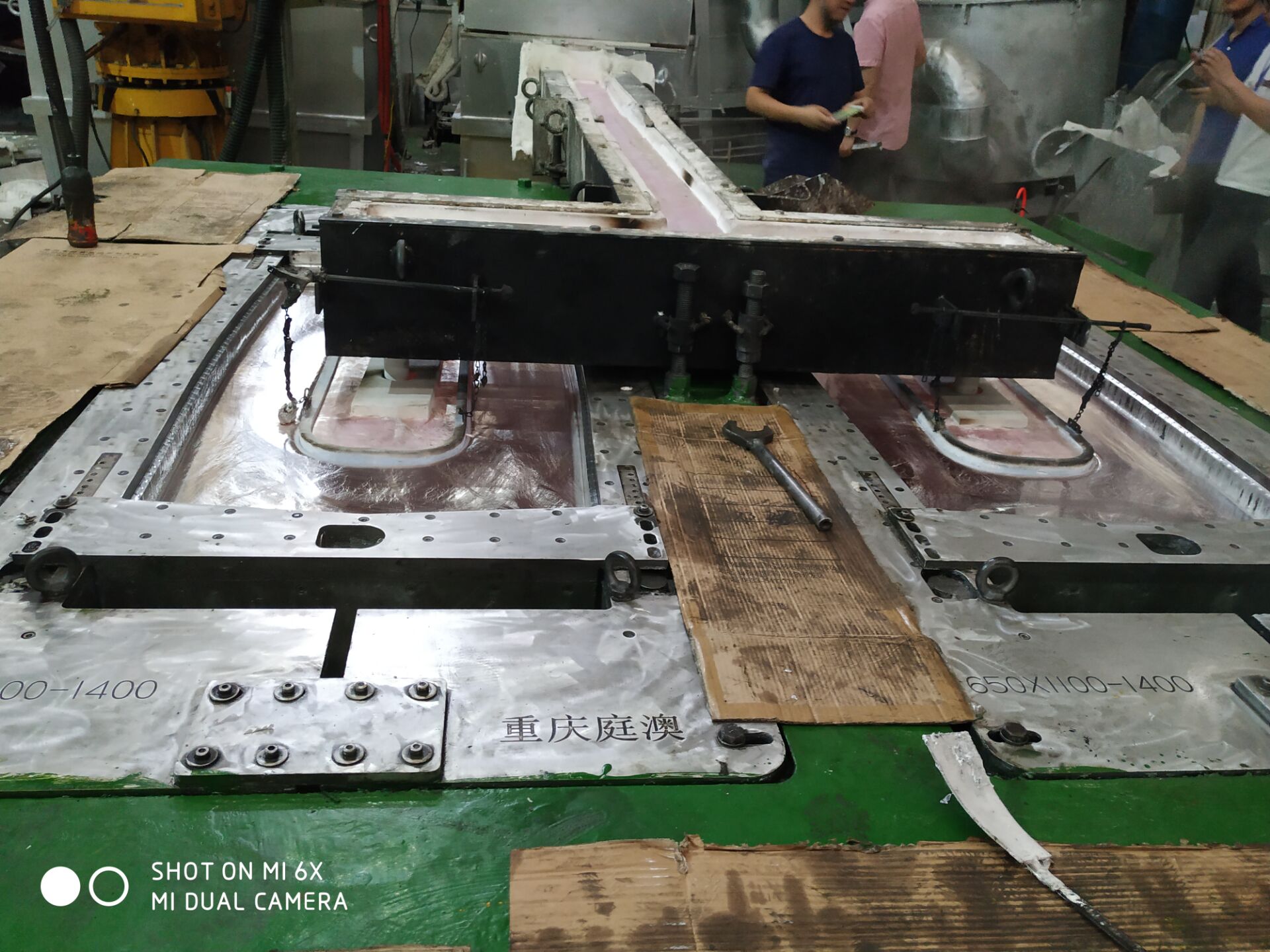

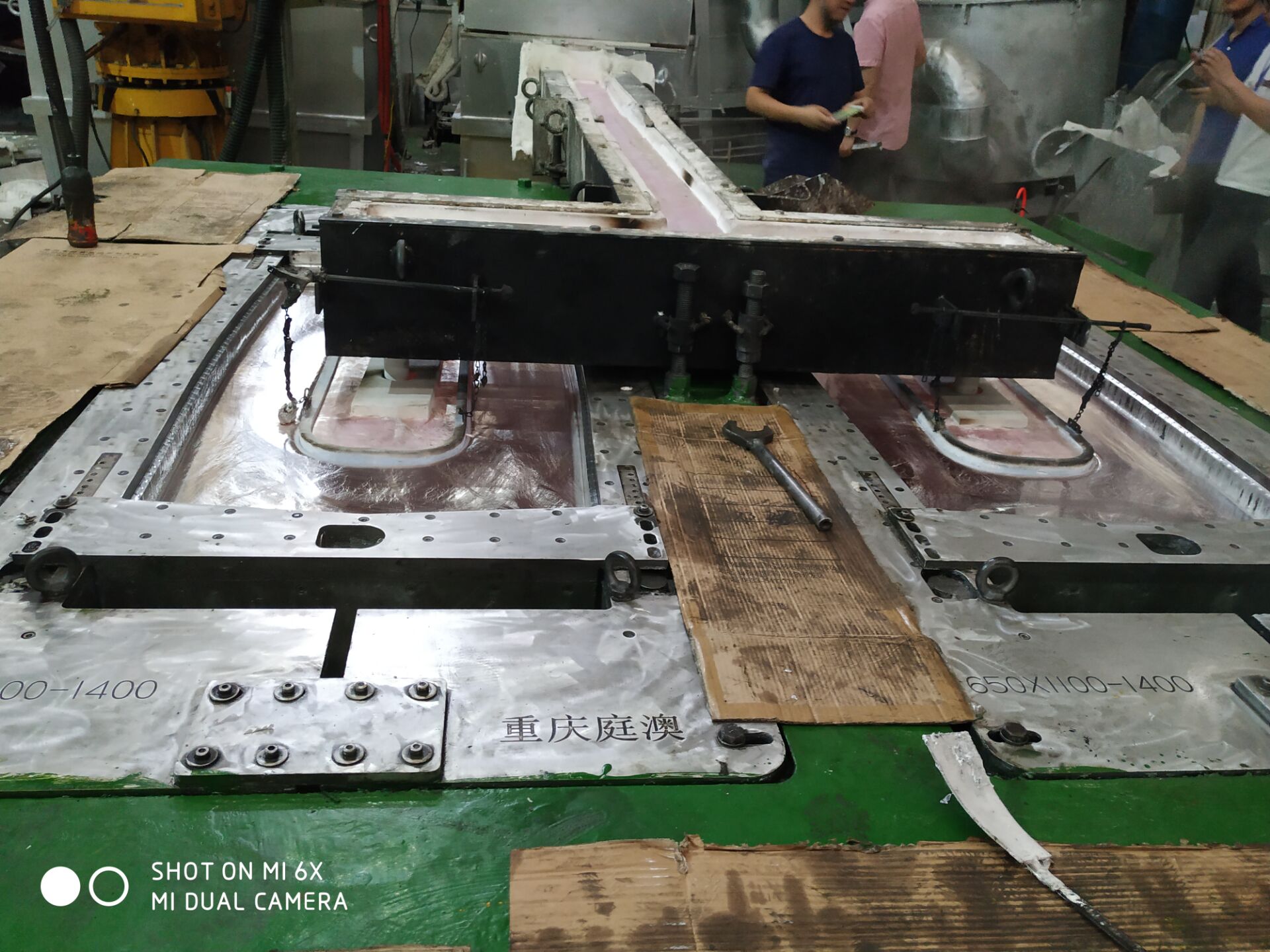

Impurity Separation Ring Product Use

AdTech is used in conjunction with casting mold. By setting the Impurity Separation Ring, the filtered aluminum liquid first enters the annular range formed by the slag ring body, and slag such as oxidized slag may be brought in. In the crystallizer, the body of the aluminum industrial slag blocking device can intercept the slag such as oxidized slag, and prevent it from flowing into the inner side of the slag ring, and control the scum such as oxidized slag to be outside the slag ring, thereby reducing the aluminum alloy. The risk of ingots being contaminated by slag.

No Comments