08 4月 Krasnoyarsk Aluminium Smelter

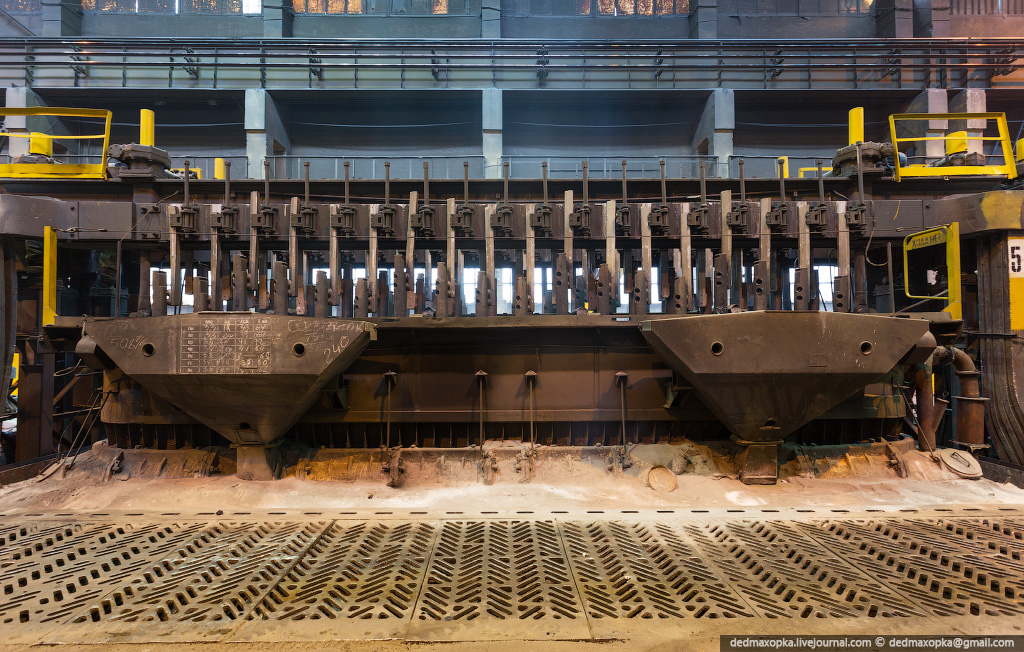

Krasnoyarsk Aluminium Smelter

Krasnoyarsk Aluminium Smelter is one of the largest smelters in the world. This facility is RUSAL’s key site for testing and introducing new cutting-edge technologies.

One of the largest aluminium smelters in the world, accounting for around 29% of aluminium production in Russia and 2% of the global aluminium output

RUSAL’s core facility for testing and deploying new innovative technologies

The plant is focused on high quality products with a 36% share of hi-tech products and alloys. It’s the only smelter in Russia and CIS to produce high-purity aluminum.

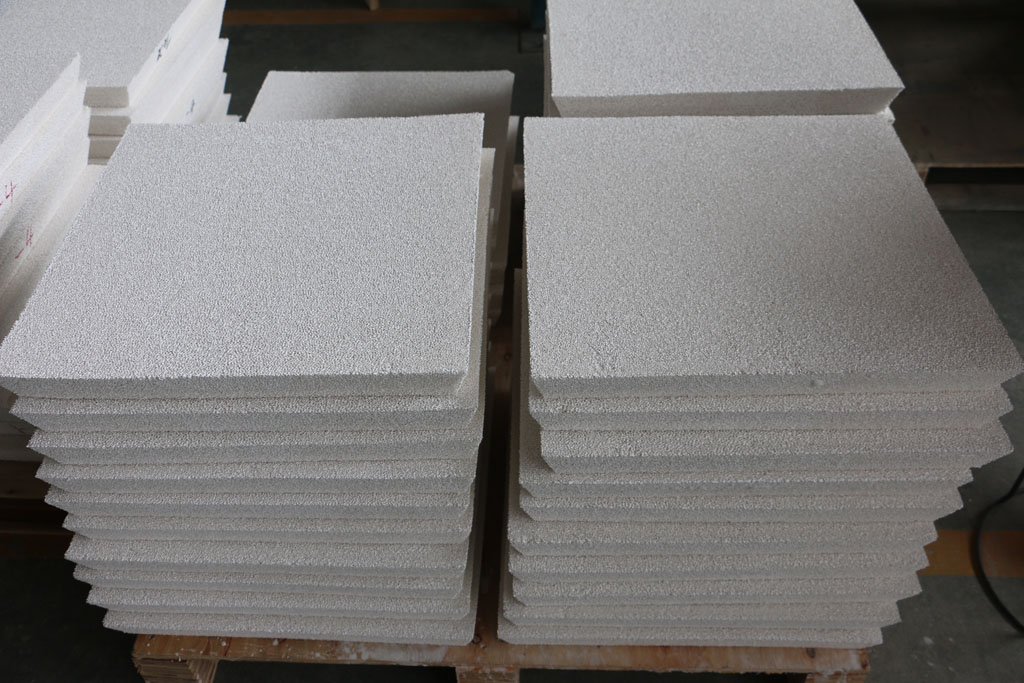

Aluminium ingots at the foundry shop of the Rusal Krasnoyarsk aluminium smelter in Krasnoyarsk, Siberia.

Although Rusal, as the name suggests, is a Russian company with most of its smelting capacity sitting in the Siberian heartland, its raw materials operations are global.

It mines bauxite in Jamaica, Guinea and Guyana and operates refineries to convert bauxite into alumina in Jamaica, Ireland and Ukraine. Each one of these subsidiaries has its own subset of sanction problems.

But Rusal activities run deeper still.

Although on paper it is almost self-sufficient in alumina, it, like many other producers, is a big and active trader, swapping tonnages across regions.

In 2017 it sold more than two million tonnes of alumina to third parties and bought just under that amount.

This largely hidden layer of the supply chain has caused US sanctions to ricochet in totally unexpected directions.

Consider the case of the Aughinish refinery in Ireland.

If Rio Tinto halts deliveries of bauxite to Aughinish, it closes, removing two million tonnes of alumina from the European market, which in turn causes smelter closures in Scotland, France and Iceland.

Even if physical flows could be maintained, the pricing dislocation would probably close the smelters anyway.

No Comments