18 Sep Launder System For Aluminium Casting

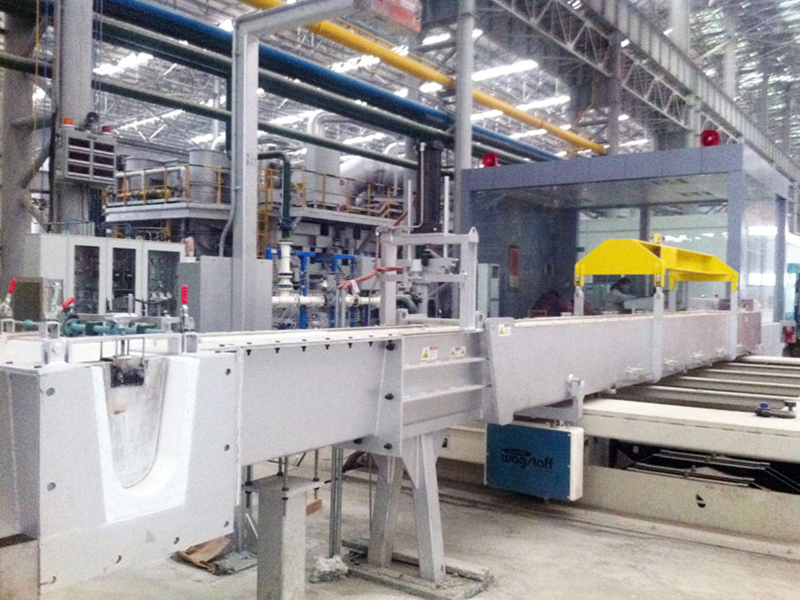

Launder System For Aluminium Casting

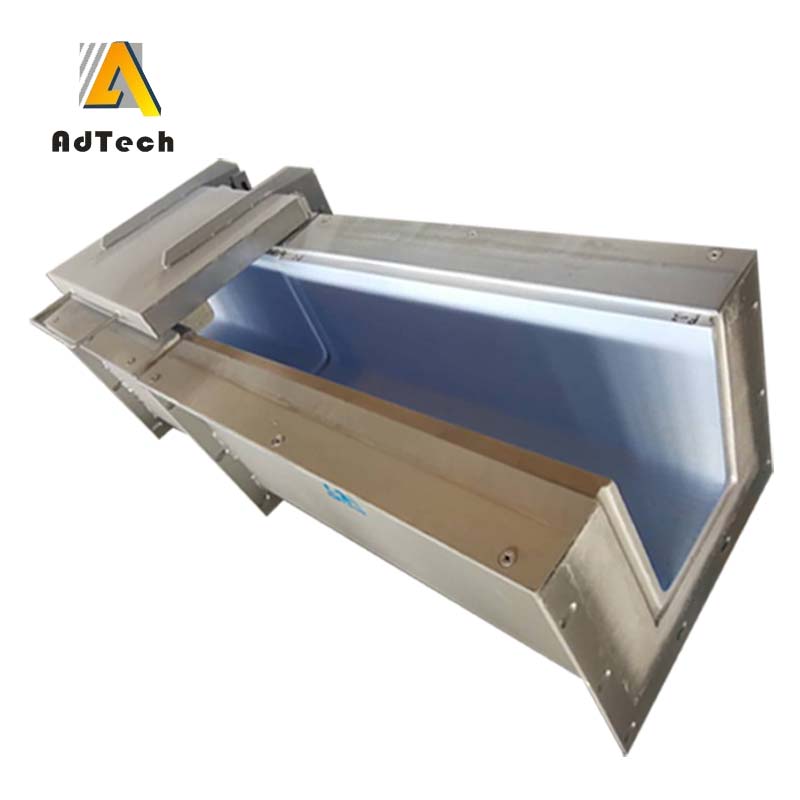

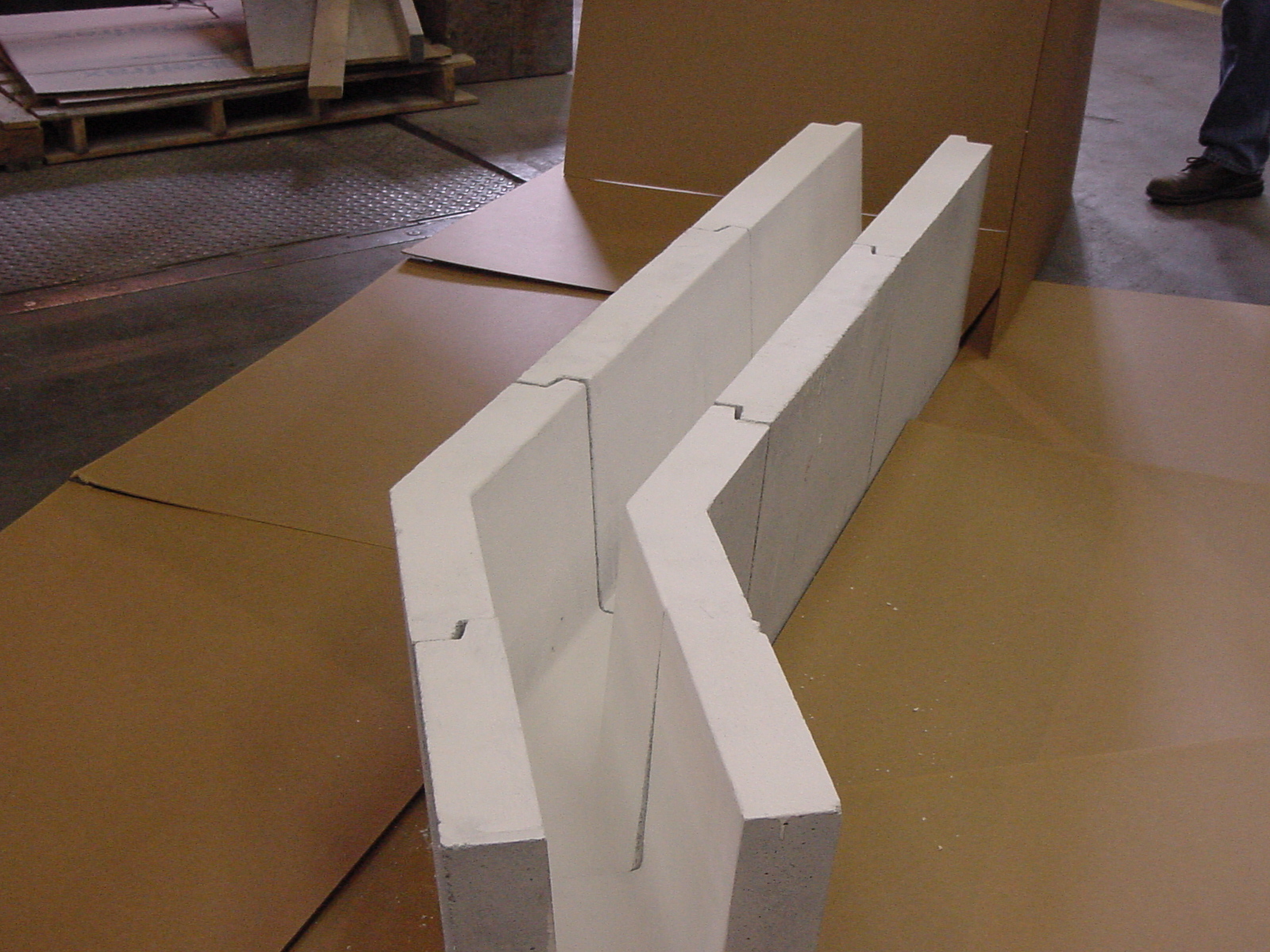

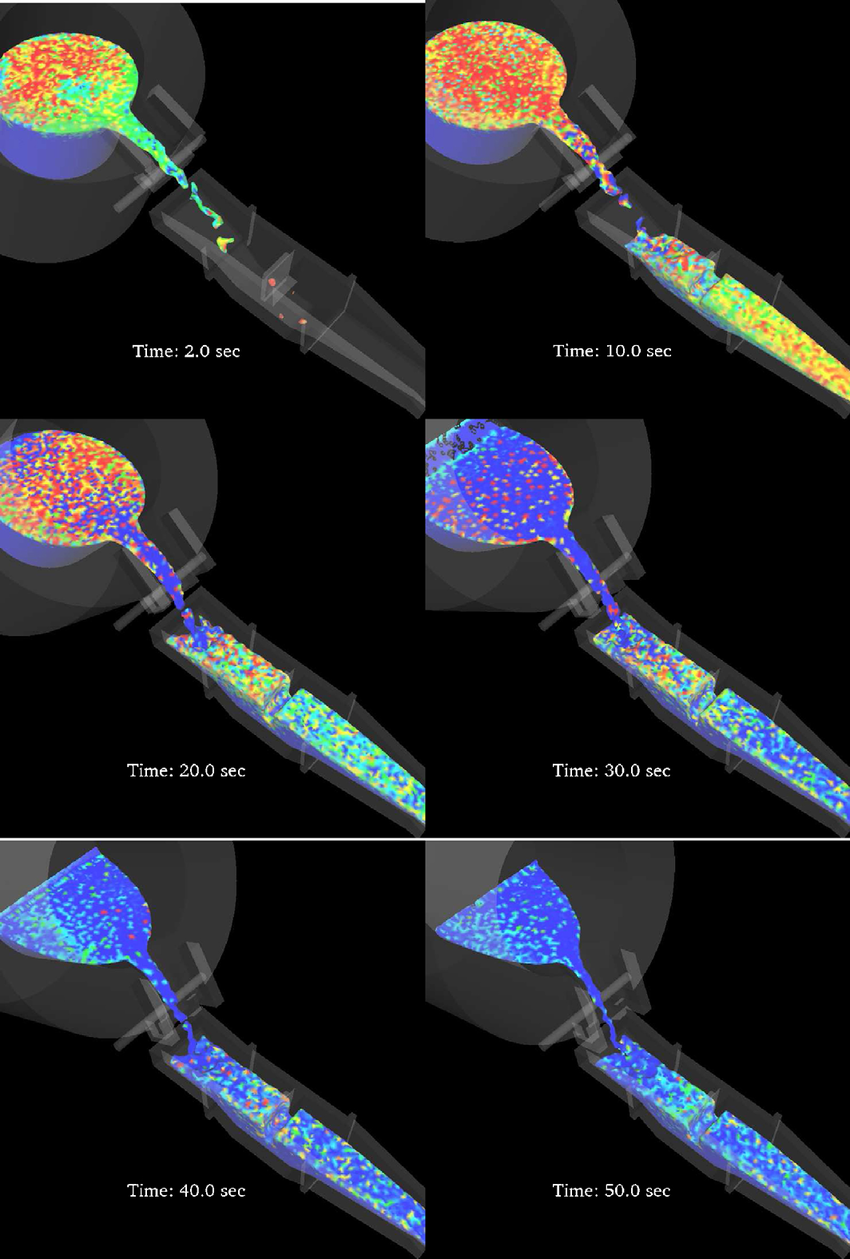

AdTech manufactures a wide range of launder segments, ranging from small segments for continuous casting, to segments for billet and rolling ingot casting, through to large segments for transfer launders. The choice of the launder cross section is made on the basis of the casting speed of the system to ensure an optimal combination of the turbulence-free flow of metal in the launder and minimised heat loss.

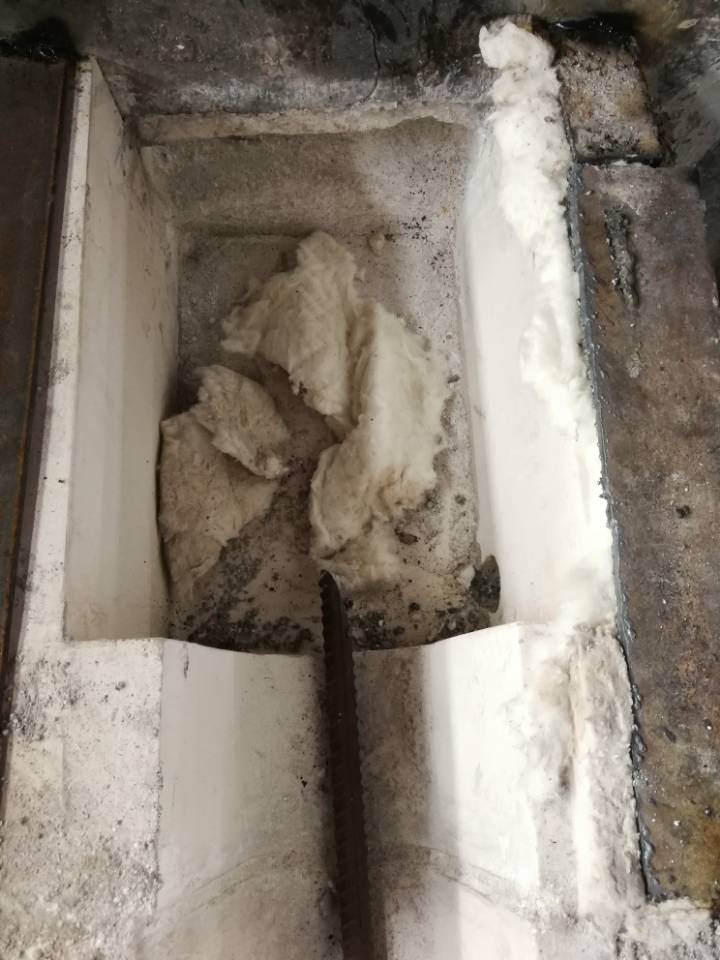

Launder System For Aluminium Casting is distinguished by their excellent erosion resistance, excellent thermal shock resistance and non-wettability. This means that outstanding endurance can be achieved, combined with minimised maintenance costs and excellent economic efficiency – given the appropriate care and maintenance.

The proven AdTech Fused Silica is generally used for casting launders. For transfer launders, we also use SiC-based materials.

Launder systems are an essential part of any casthouse. Well designed launders contribute to a smooth and efficient casthouse operation where fast transfers between furnaces are of key importance. Clean, low-turbulence casting launders play a significant role in producing high quality products.

AdTech has outstanding experience in designing and installing launder systems. This expertise is supported by the company’s own proprietary software program for the design of open and closed launder systems, the use of the most advanced launder lining materials, and launder (pre-) heating technologies ranging from gas firing for transfer launders to electric heating for casting launders.

Launder System For Aluminium Casting is sized and rated to meet the required transfer and/or casting capacities. Features and accessories may include laser launder level control systems for (semi) automatic melt transfer and automatic casting operations, high-level metal probes for anti-spill safety, launder thermocouples for fine-tuning the molten metal temperature during casting, etc.

AdTech has designed and installed many interconnecting launder systems. Not only have we supplied launder systems to suit our own equipment, we have also undertaken projects to install our launder systems on existing plant equipment.

AdTech takes a flexible approach on launder system design as we recognise each of our clients needs are different. Mechatherm will take into account our clients plant layout and shop levels along with any other interfering parameters before producing an optimum design. AdTech can also offer customised access platforms for good operator access.

No Comments