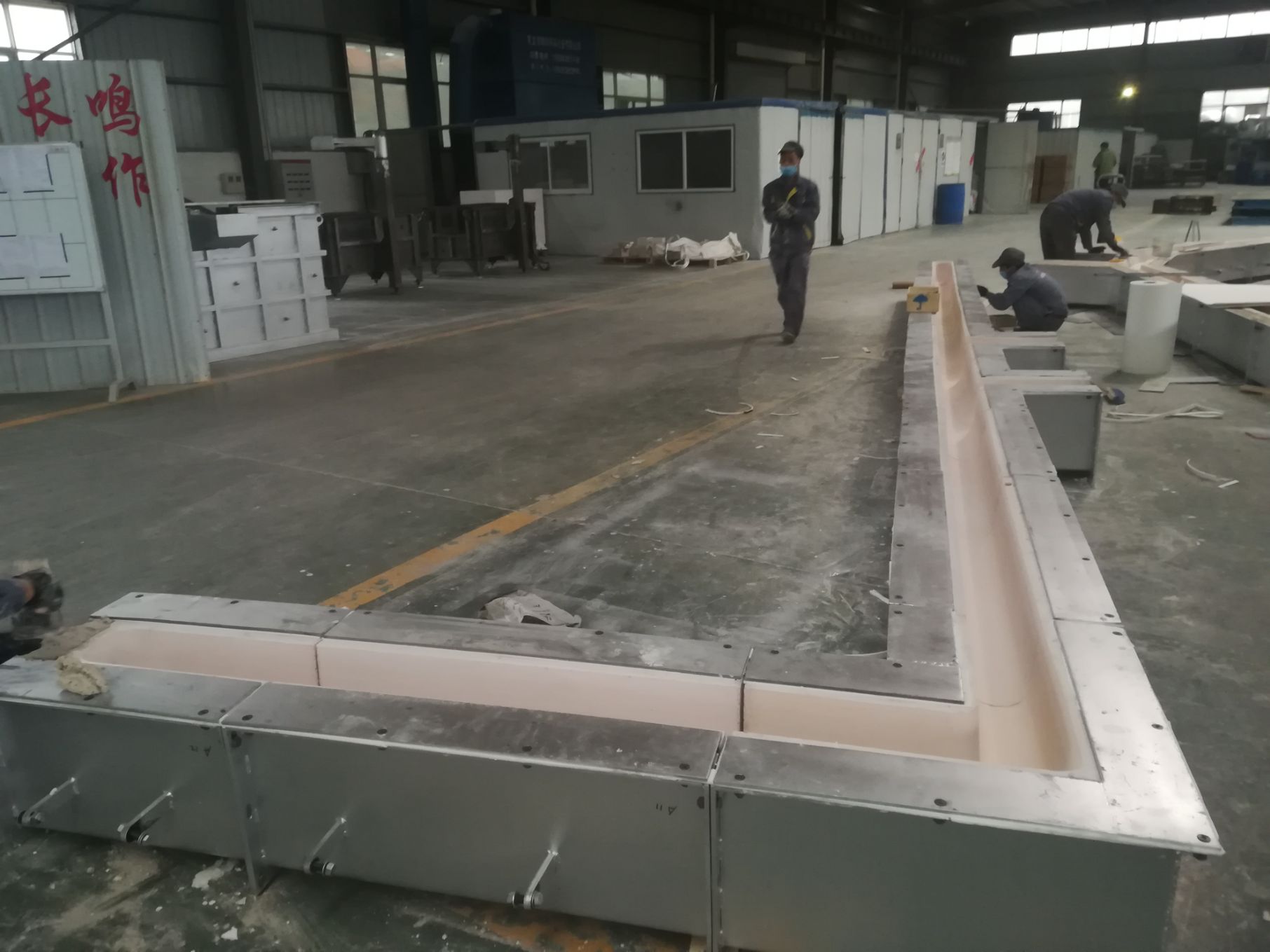

10 3月 Aluminium Launder System

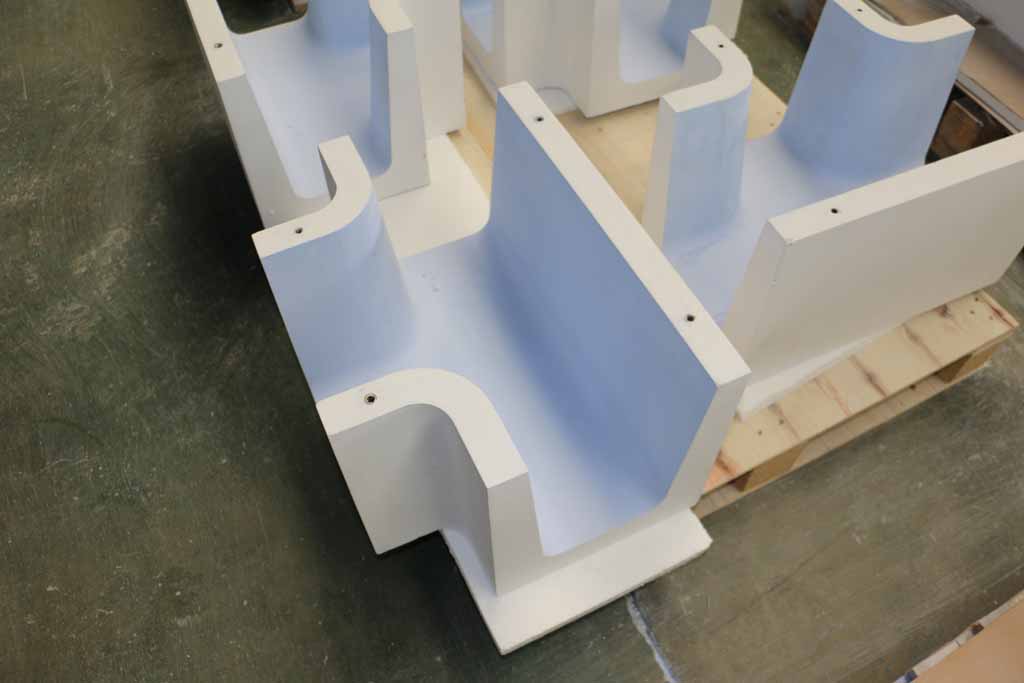

Launder System For Aluminium allows liquid aluminum to flow between smelting furnaces, holding furnaces and other processing equipment in accordance with the steps of the process.

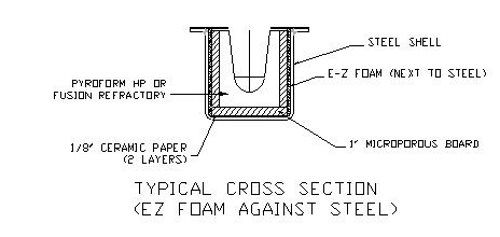

The launder is connected to the liquid aluminum outlet and leads it to the next device, and the equipment in this is what we call the aluminum liquid launder. It is mainly made of high-aluminum fiber and made of a lightweight and heat-preserving material. .

Launder System For Aluminium Application and Features

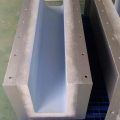

1. High density

The molten aluminum launder is a refractory material based on alumina, which is a highly dense, strong and durable product

2. Has excellent physical properties

Thermal shrinkage coefficient, small expansion coefficient, high surface strength, low heat capacity

3. Good chemical stability

No asbestos content, no chemical reaction with aluminum melt

4. Good insulation performance

The aluminum liquid launder has good thermal insulation performance, and the high-aluminum fiber is used as the material, which has good thermal insulation performance.

Advantages of Launder System For Aluminium

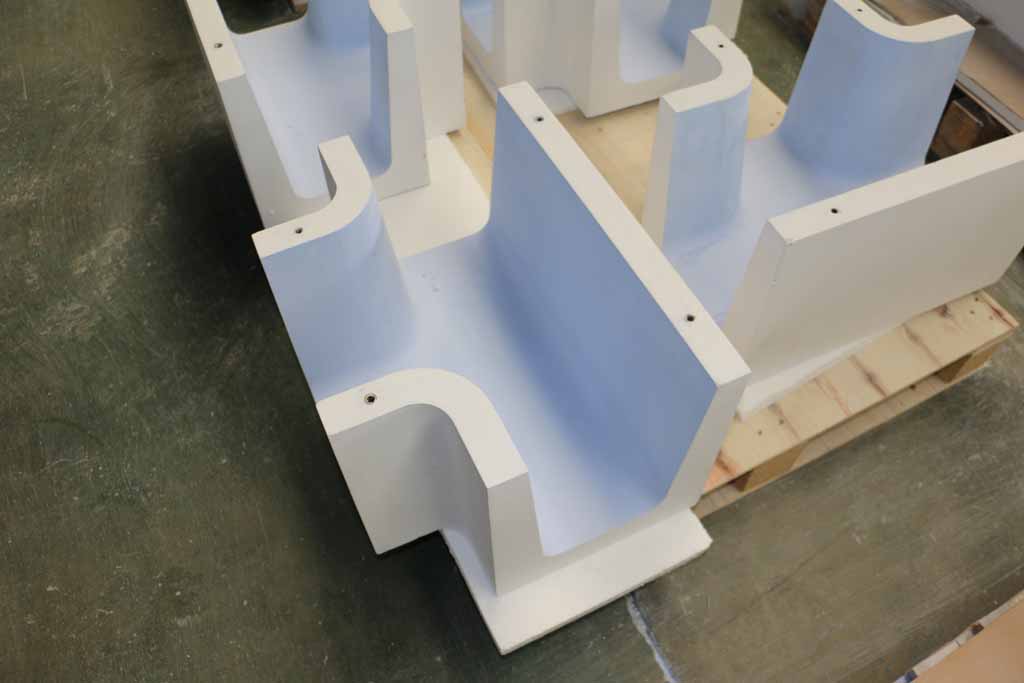

1. The aluminum liquid movable trough has good thermal insulation performance, and can achieve a temperature drop within 1 ℃ per meter.

2. It does not react with aluminum liquid at working temperature, has low density, good non-stick aluminum performance, and flexible casting and rolling operation;

3. The movable flow trough of molten aluminum is integrally formed with high-silicon melt material, with high dimensional accuracy;

4. The movable flow trough of molten aluminum can be used repeatedly or multiple times, and the surface is smooth.

5. Good anti-sticking aluminum performance, easy to remove the condensed shell

6. Anti-scouring, sturdy and durable

7. The volume is super stable, resistant to cold and heat shocks; it reduces the maintenance of the joints between the sections and saves costs.

Launder System uses

The movable runner produced is used between the on-line degassing filter equipment and the casting and rolling mill. It has dual functions: conveying and heat preservation, with a repetitive or multiple-used lining, and adopts a new high-silicon molten material molding technology, which has a certain degree of corrosion resistance. Power, non-stick aluminum, and non-polluting to molten aluminum. It is mainly used for aluminum alloy products such as medium and micron aluminum foil wool for precision casting and rolling of aviation and transportation, and PS plate base for printing.

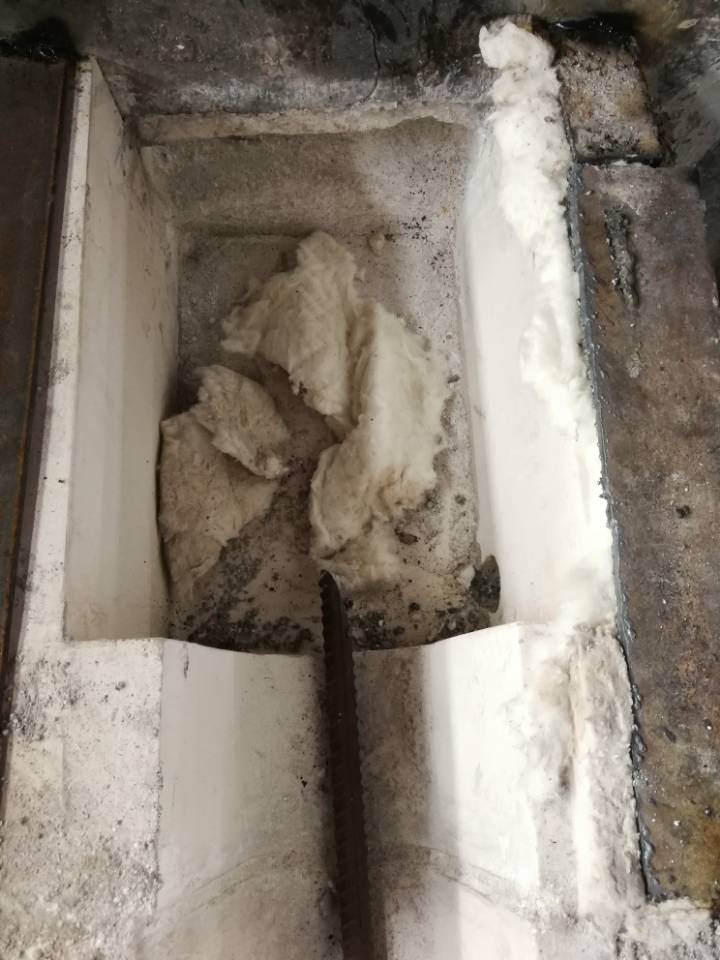

Launder System instructions

1. Corresponding to the drawing structure, install the movable runner to ensure that the movable runner is clean, free from damage and seamless.

2. Uniform preheating of the installed standard movable launder, heating at a constant speed for 1-2 hours, check that the surface of the lining is red, that is, within 800℃, to remove the adsorbed crystal water, close to the casting temperature, and use it safely and efficiently.

3. The movable trough has no electric heating and baking conditions, so it has to be baked with flame. One of the key is to control the flame temperature, and the other is to avoid direct burning of the flame, and to avoid thermal stress caused by local heating to cause the lining to burst. The flame is divided into weak flame (red soft flame), medium flame (yellow), strong flame (blue and white).

No Comments