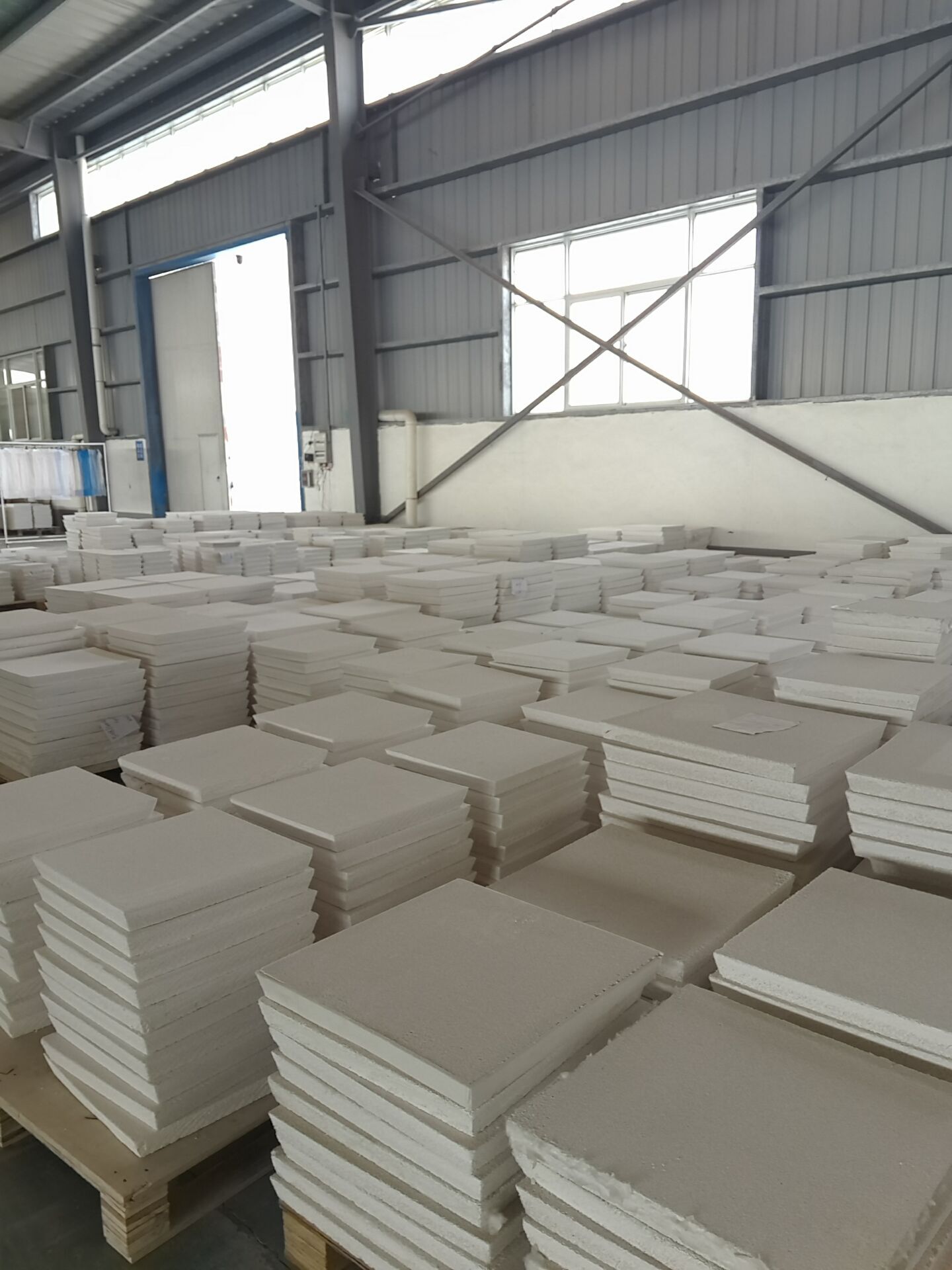

22 7月 Made In China Filter Foam Ceramic For Sale

Made In China Filter Foam Ceramic For Sale

Made In China Filter Foam Ceramic For Sale, can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield.

It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

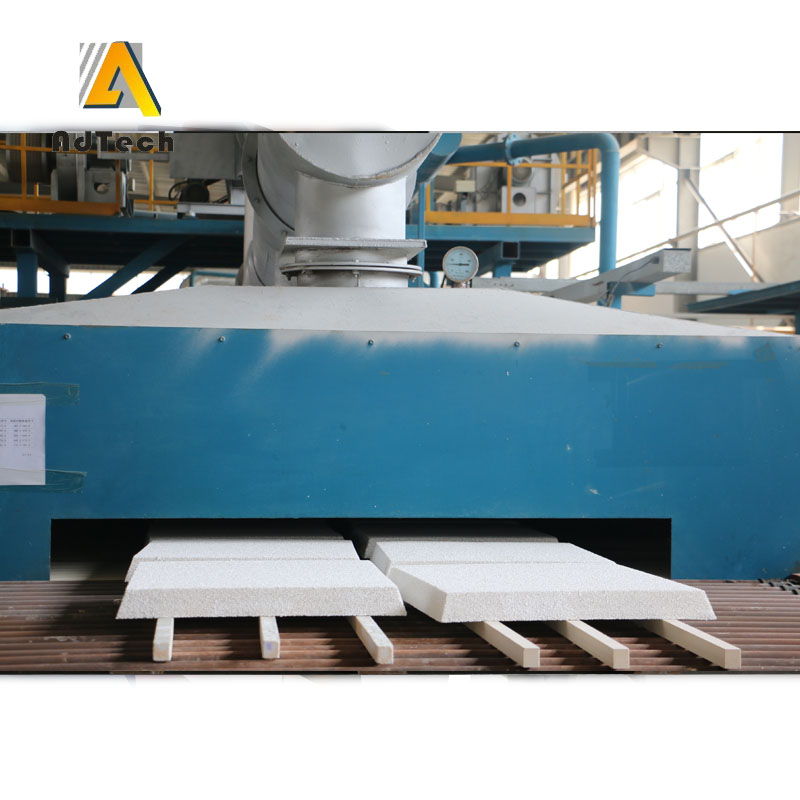

Made In China Filter Foam Ceramic For Sale, uses a three-dimensional network structure and an organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropic properties, and adopting a special roll extrusion process to uniformly apply the ceramic slurry to the skeleton of the carrier.

Then, it is dried and solidified and then fired at a high temperature.

Porous Ceramic Foam Filter Foam Ceramic Filters for Aluminum Alloys Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Porous Ceramic Foam Filter uses polyurethane foam as a carrier, immersing it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruding excess coating to uniformly apply the ceramic coating to the carrier.

The skeleton becomes a green body, and the green body is dried and fired at a high temperature.

Transmittance of Made In China Filter Foam Ceramic For Sale

Transmittance refers to the effective filtration area of the ceramic foam filter plate product.

The higher the light transmittance, the less blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

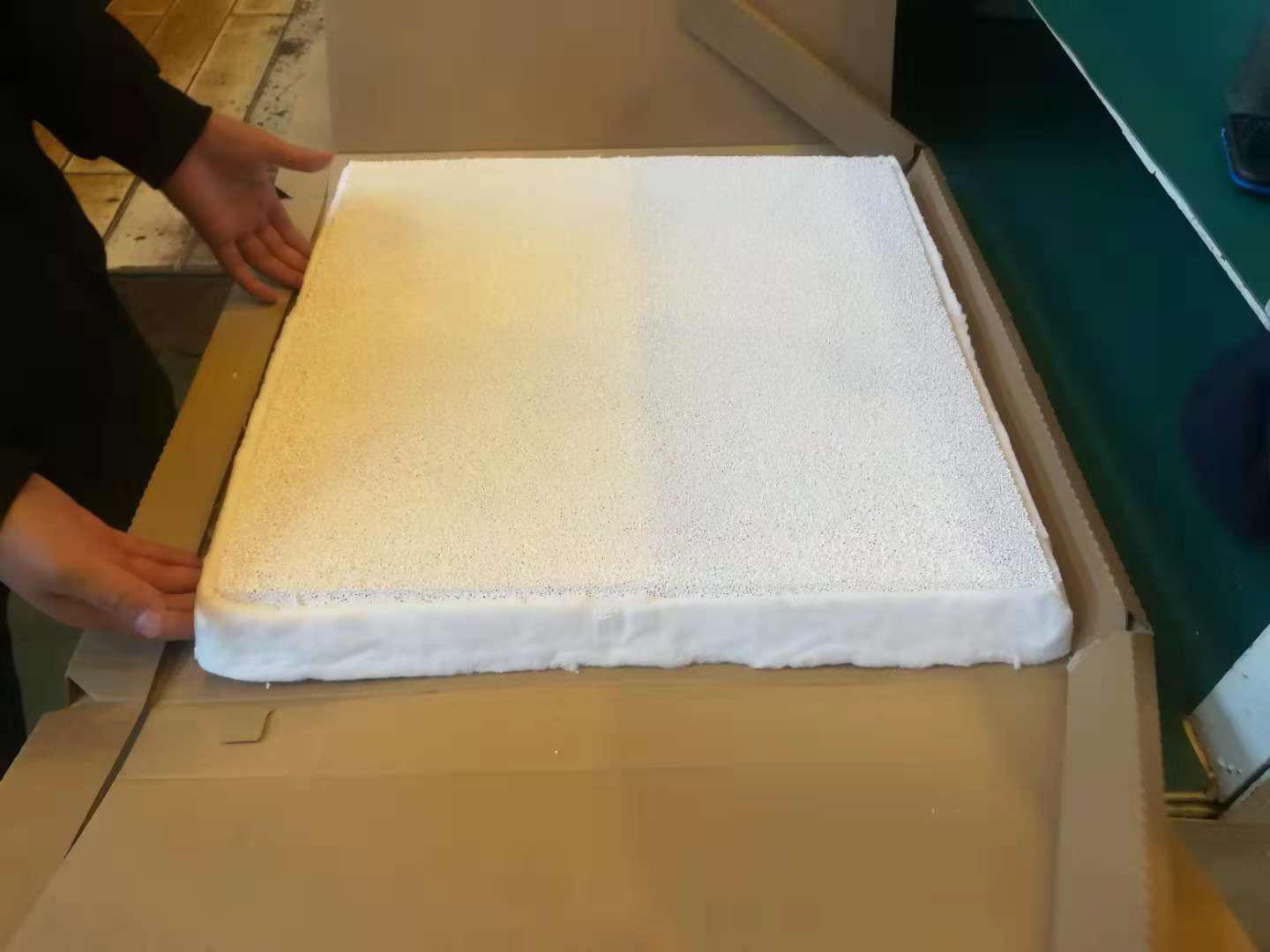

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb.

The square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the area of the large surface of the filter plate, so as to calculate the test.

The light transmittance of the filter plate is used to determine the light transmittance of the filter plate.

In this standard, the transmittance (through-hole ratio) of the filter plate is specified to be 95% or more.

The Compressive Strength of Made In China Filter Foam Ceramic For Sale

In the process of transportation and use of the filter plate, the filter plate must withstand the impact of a certain pressure from the outside.

So the index of compressive strength is also introduced in the standard as one of the basis for measuring the quality of the filter plate. The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

In this standard, the index of compressive strength is determined to be 0.5 MPa or more.

How to choose Made In China Filter Foam Ceramic For Sale

There are many impurities, and the quality of cast products is general.

Ceramic filter plates with larger meshes are available, and a glass cloth coarse filter is added in front of the filter plates.

At this time, semi-continuous casting is important for coarse filtration with a glass cloth.

It can intercept the slag from the opening of the eye and the slag washed out by the launder to prevent clogging of the filter plate.

The quality of aluminum casting products is high, and the new type of foam ceramics with large mesh size is selected.

The specification of the ceramic filter plate is determined by the flow rate and total throughput of the aluminum melt.

The color is pure and no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, and will not cause secondary pollution.

The effective specific surface area or porosity calculation of the foam should be carefully evaluated when purchasing the filter.

The mesh surface homogenization state of the filter plate can be observed, and then the cross-sectional mesh homogenization state is observed. If possible, the porosity can be calculated by the drainage method.

The three-dimensional mesh is homogeneous and the porosity is relatively large, which is an excellent ceramic filter plate.

ADTECH keeps focusing on the manufacture of the metallurgical material. www.adtechamm.com

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

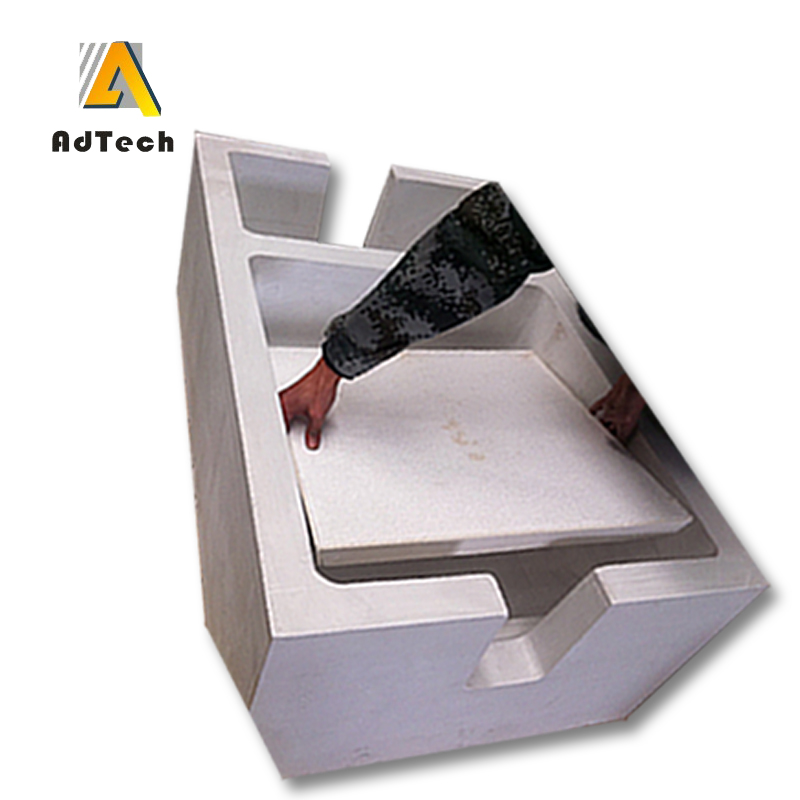

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

Sorry, the comment form is closed at this time.