20 8月 Metal Foam Filter Factory

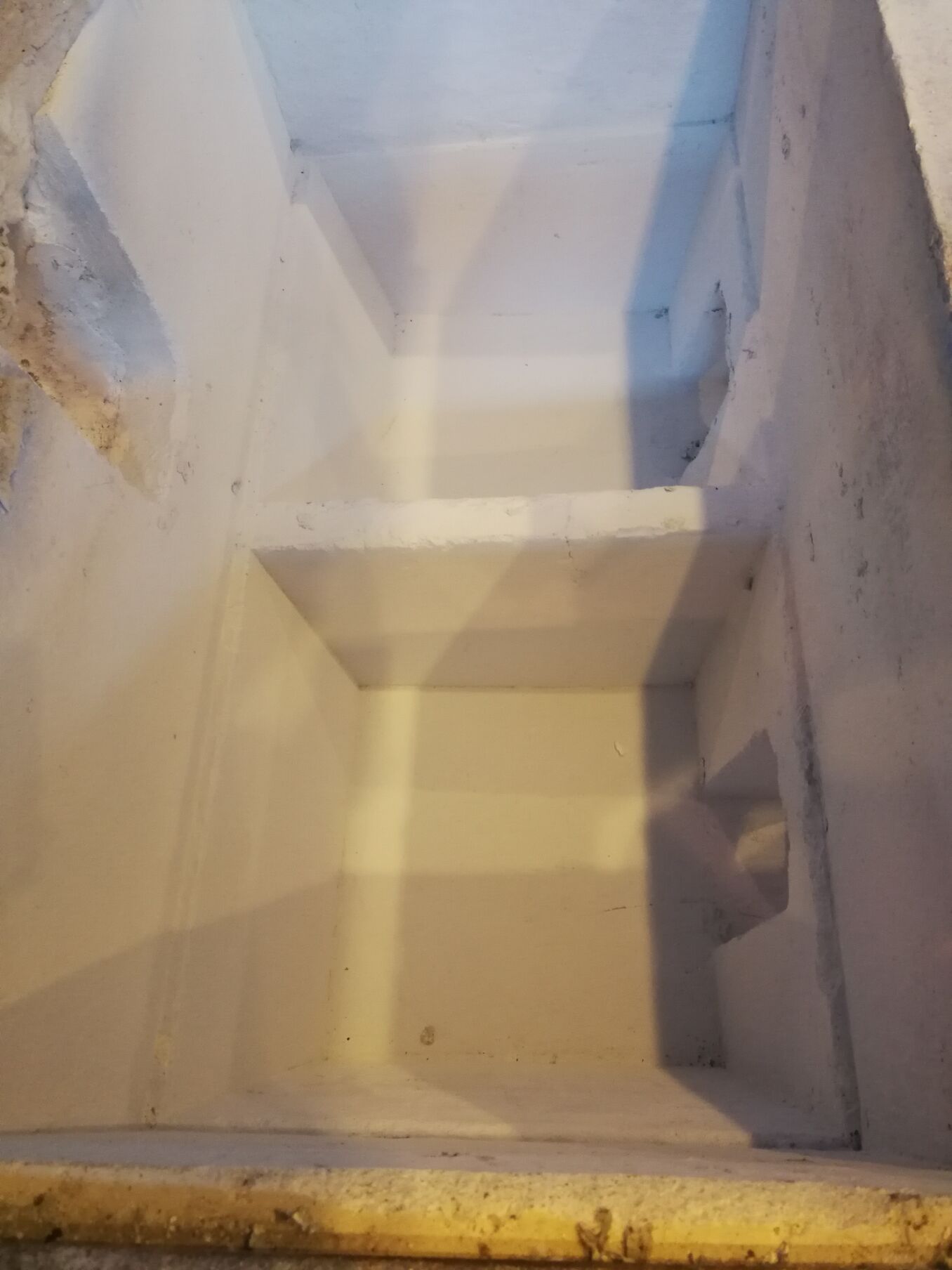

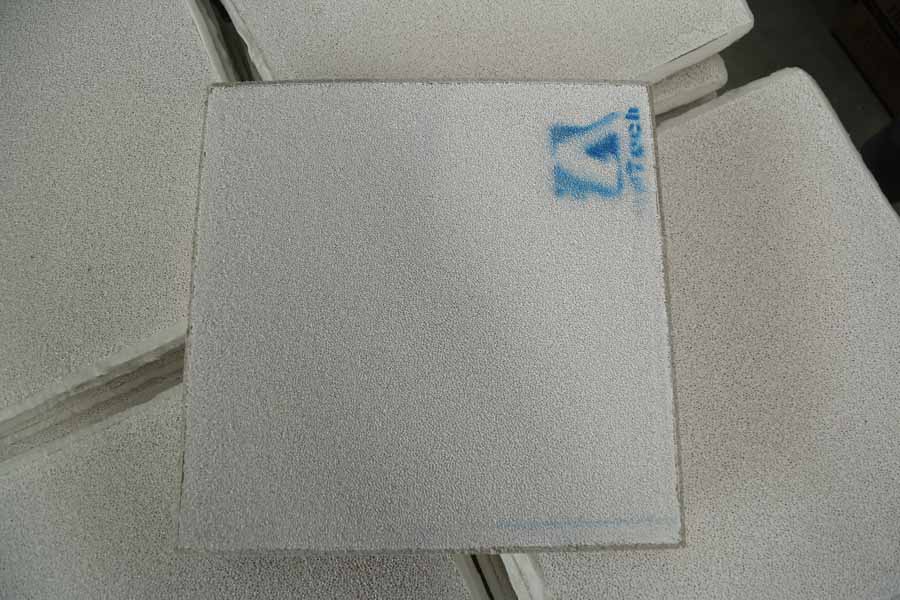

Metal Foam Filter Factory AdTech has developed a new type of molten metal foam filter in recent years to reduce casting defects.

Metal Foam Filter has the characteristics of light weight, high mechanical strength, large specific surface area and high porosity.

Molten metal has excellent thermal shock resistance, chemical resistance and high temperature stability.

Through the distributed pore network structure, they can increase the surface area and absorb sinter, the liquid metal becomes more pure, and greatly reduces the occurrence of waste quality problems such as blisters and holes.

Features and advantages

Metal Foam Filter Factory AdTech provides the best way to eliminate non-metallic inclusions in aluminum solution, these inclusions are the main source of casting quality problems.

When casting products, remove molten metal, refractory waste, solid refractory alloys, impurities in sintered ore, eliminate turbulence, reduce casting porosity, and improve casting quality.

Therefore, our Metal Foam Filter is widely used in the aluminum casting industry to prevent defects caused by oxides, scum, gas, slag and other impurities.

The turbulence in the metal flow is eliminated, the metal flow is stabilized, and spray, splash and collapse are avoided. Improve fluidity, castability, workability, output and cost-effectiveness.

Remove a larger proportion of fine particles, reduce waste and rework

Low pressure loss.

Provide consistent flow rate and capacity.

How high efficiency filtration improves the whole process

Alumina ceramic foam filter has the following advantages

1.3D grid structure

2. High mechanical strength, no residue during beating

3. High porosity

4. Large surface area, strong impurity absorption capacity

5. Excellent thermal shock resistance

Denmark Aluminium said that Metal Foam Filter Factory AdTech’s products can effectively remove and absorb various impurities in molten aluminum, thereby improving surface quality, product performance and microstructure effectiveness.

Mainly used for precision casting of aluminum alloys such as household, construction, electric power, condenser tubes, cables, etc.

Denmark Aluminium engineers are recommending Adtech Filter to other aluminum plants in Denmark in order to make the molten aluminum more pure.

Denmark Aluminium has a suggestion

1. Aluminum alloy bar selection: 10-30ppi

2. Long-term casting options: 30-50ppi

3. High-quality aluminum profile or plate selection: 40 or 50ppi

4. Double zero wave continuous casting and rolling options:> 50ppi

Sorry, the comment form is closed at this time.