18 Jun Molten Aluminium Define Degassing

Molten Aluminium Define Degassing

Molten Aluminium Define Degassing. The hydrogen partial pressure in the nitrogen bubble just emerging from the graphite nozzle is 0. When the nitrogen floats, the hydrogen diffuses from the aluminum liquid into the nitrogen bubble under the driving force of the hydrogen pressure difference, and the process until the hydrogen partial pressure in the nitrogen bubble When the hydrogen partial pressure in the aluminum liquid is balanced, the nitrogen phase is stopped, and then the nitrogen gas is floated up to the surface to be removed, thereby degassing.

AdTech refined the volume of nitrogen bubbles by improving the rotating nozzle in the process of purifying nitrogen purification, and increased the contact area between nitrogen and aluminum, thereby improving the effect of degassing and slag removal, and achieving the purpose of aluminum purification. Improve the quality of the product.

The online degassing unit has always been the subject of research on aluminum alloy casting and rolling, and the purity of the nitrogen used for refining in the purification device is a key factor that directly affects the purification effect.

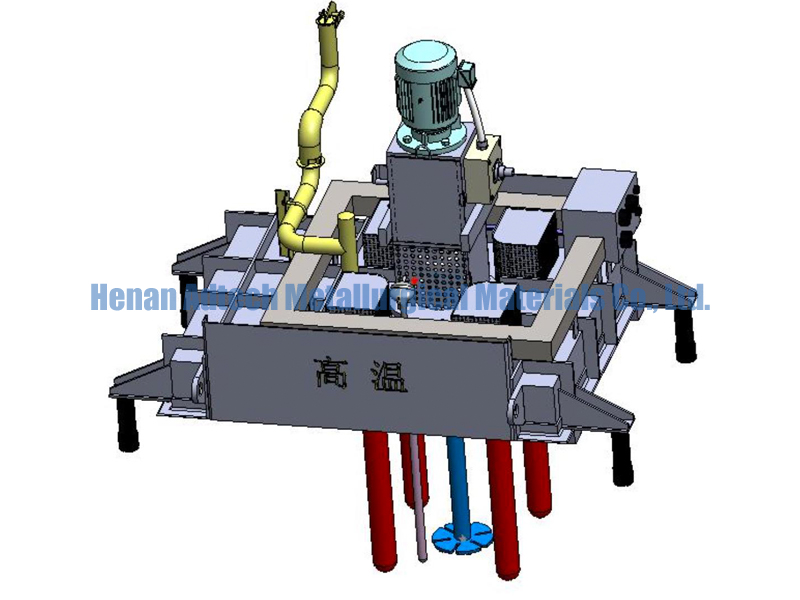

Adtech Degassing Machine is mainly used for the hydrogen (H) and slags removal from molten aluminum.

It takes the gas flotation principle. The rotor takes inert gas or a mixture of chlorine and inert gas into molten aluminum and smashes the gas into dispersed tiny bubbles, the bubbles rise to molten aluminum surface and finish the below-stated procedures at the same time:

H is being absorbed in bubbles and is being removed.

The chloride is removed (formed by chemical action with an alkali metal and chlorine gas).

Remove slags.

Sorry, the comment form is closed at this time.