06 Jan Molten Aluminum Degasser

Molten Aluminum Degasser

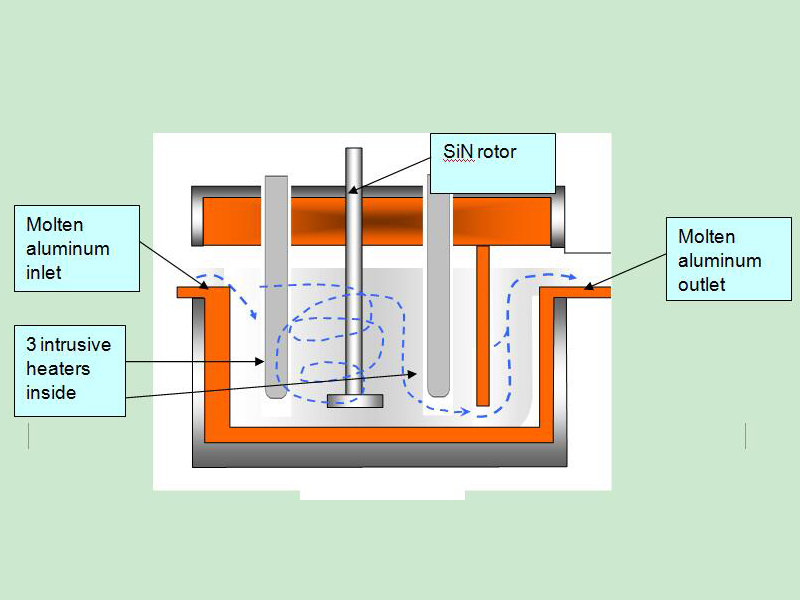

Molten aluminum degassing usually uses a mixture of argon and chlorine.

As the name implies the purpose of this treatment is to reduce the hydrogen content of the metal.

However, it also aims to improve mental cleanliness by flotation of inclusions to the surface to form dross. As several workers reported, a small percentage of chlorine in the gas mixture used offers benefits in terms of inclusion removal.

Since chlorine hurts the agglomeration of TiB2 particles, the addition point of the grain refiner is worthy of consideration.

Adding grain refiner into the degasser entry point has proven beneficial.

The turbulence of the metal in the degasser provides excellent conditions for rod melting and rapid distribution of the grain refiner particles. However, there is evidence of grain refiner particles being lost to the dross.

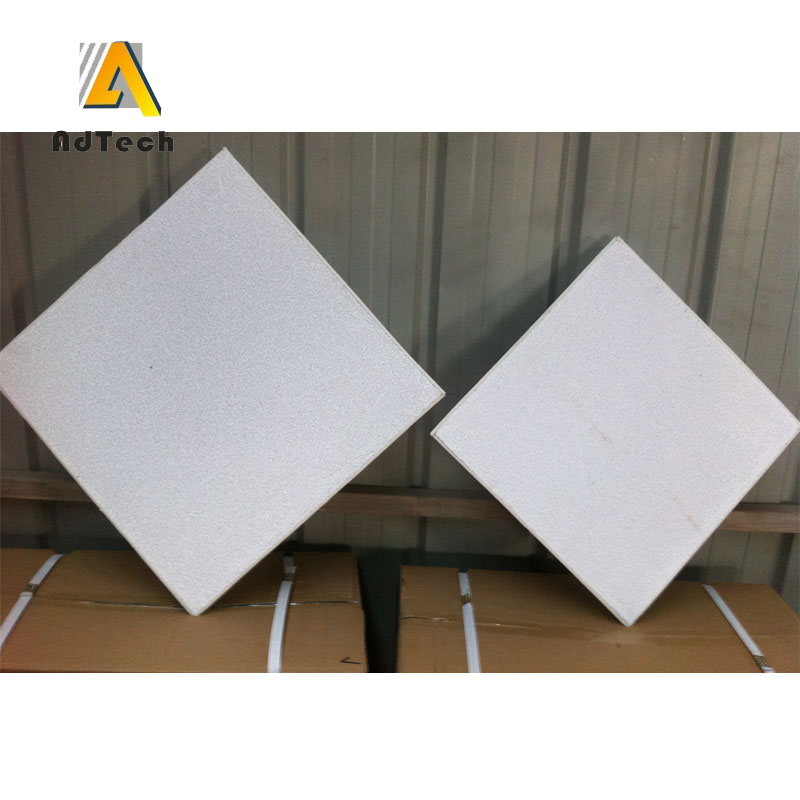

molten aluminum

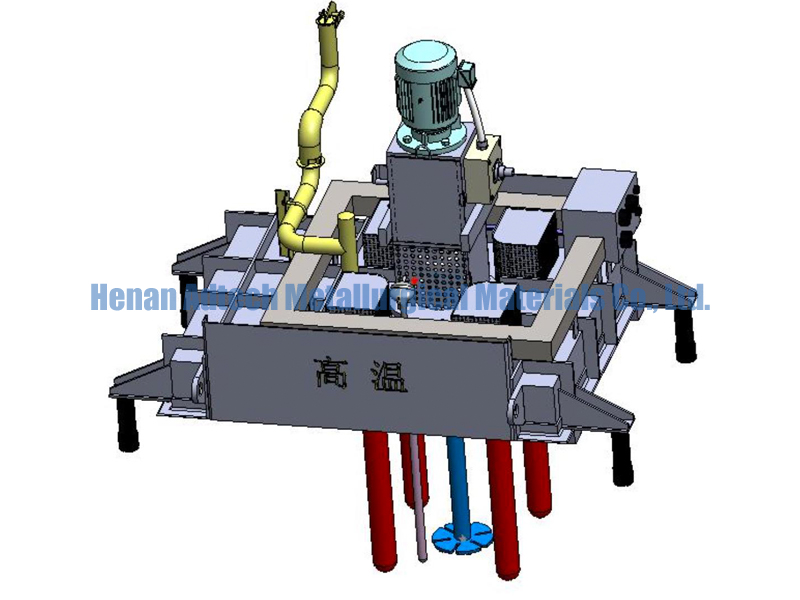

degassing system

While degassing with chlorine the conditions are conducive to agglomeration of TiB2 particles.

Apart from the role of chlorine, the input metal is relatively rich in oxide films compared to the output metal.

Furthermore, the metal turbulence inside the degasser encourages particle collisions.

Individual cast houses have been able to demonstrate these effects using LiMCA technology.

All of these issues would tend to suggest it is preferable to add grain refiner after a degasser rather than before it, particularly if chlorine gas is being used.

This is dependent on the cast house layout however, as the addition point needs to also take into account the cleanliness of the grain refiner, and the time required for dissolution of particles.

No Comments