06 12月 Molten Aluminium Flow Box

Molten Aluminium Flow Box

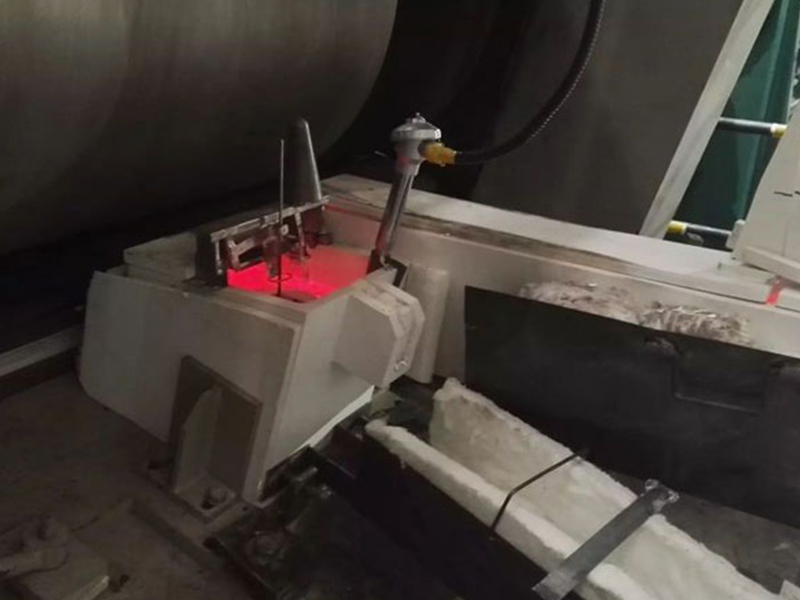

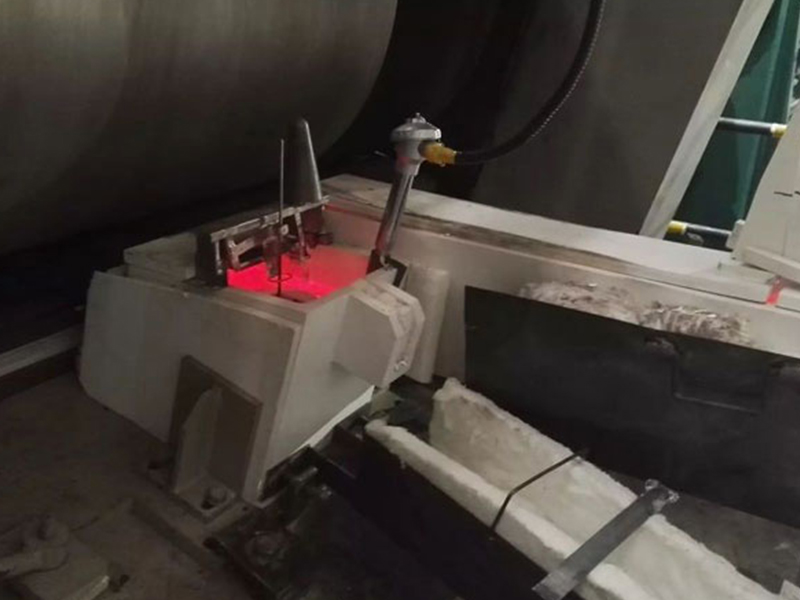

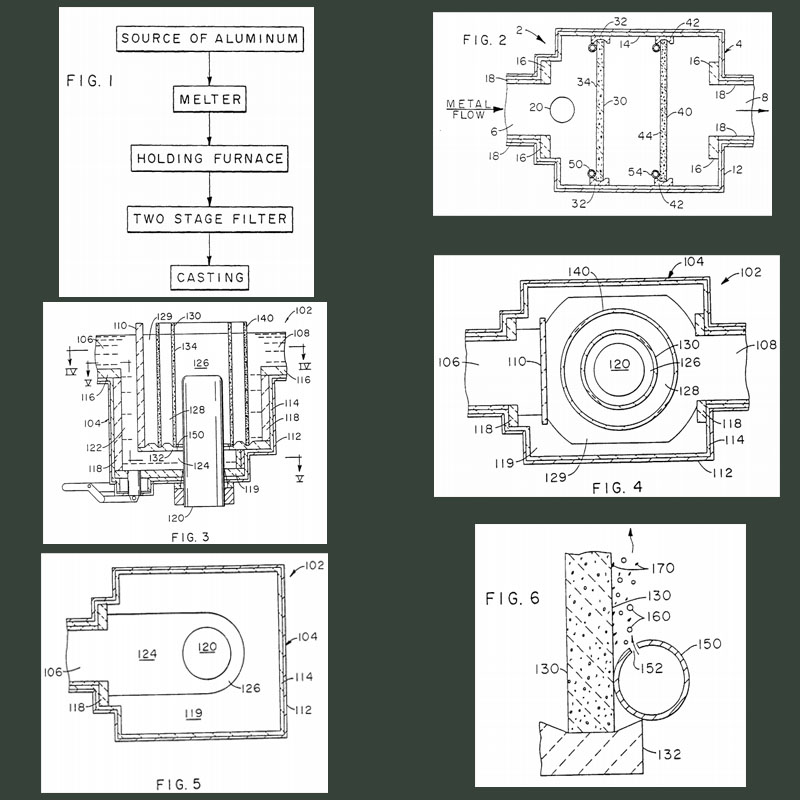

1. Molten Aluminium Flow Box comprising:

an upper rectangular-shaped section;

a lower inverted pyramidal-shaped section;

a unitary dual nozzle assembly located in a bottom region of the lower inverted pyramidal-shaped section.

2. Molten Aluminium Flow Box comprising:

an upper rectangular-shaped section;

a lower inverted pyramidal-shaped section housing a unitary dual nozzle assembly having a pair of nozzles, the unitary dual nozzle assembly positioned within a bottom region of the lower inverter pyramidal-shaped section, the unitary dual nozzle assembly constructed of a thermally conductive material and insulated from contact with the lower inverted pyramidal-shaped section, and in thermal contact with the molten metal contained within the molten metal holding and pouring box during pouring and non-pouring periods through the pair of nozzles; and a pair of stopper rods, the pair of stopper rods engaging the pair of nozzles for controlling the flow of the molten metal to be poured through each of the pair of nozzles.

3. The Molten Aluminium Flow Box wherein the molten metal holding and pouring box comprises an outer structural supporting layer and at least one inner insulating material layer to maintain the temperature of the molten metal within the molten metal holding and pouring box.

4. The Molten Aluminium Flow Box wherein the unitary dual nozzle assembly is constructed of a material selected from the group consisting of alumina and silica.

5. The Molten Aluminium Flow Box wherein each of the pair of nozzles has a conical funnel-shaped inlet and a nozzle insertion end of each of the pair of stopper rods is arranged so that when the nozzle insertion ends of the pair of stopper rods are inserted in the conical funnel-shaped inlet of the pair of nozzles to stop the flow of the molten metal through the pair of nozzles a portion of the conical funnel-shaped inlet in each of the pair of nozzles is in contact with the molten metal in the molten metal holding and pouring box.

6. The molten metal holding and pouring box further comprising a unitary dual nozzle retention plate removably fastened to the bottom of the pyramidal-shaped lower section of the molten metal holding and pouring box around the outlet of each one of the pair of nozzles in the unitary dual nozzle assembly.

7. The molten metal holding and pouring box wherein the unitary dual nozzle retention plate is removably fastened to the bottom of the pyramidal-shaped lower section of the molten metal holding and pouring box by a pair of retaining posts fastened to the bottom of the pyramidal-shaped lower section and a retention fitting passing through each one of the retaining posts below the unitary dual nozzle retention plate.

No Comments