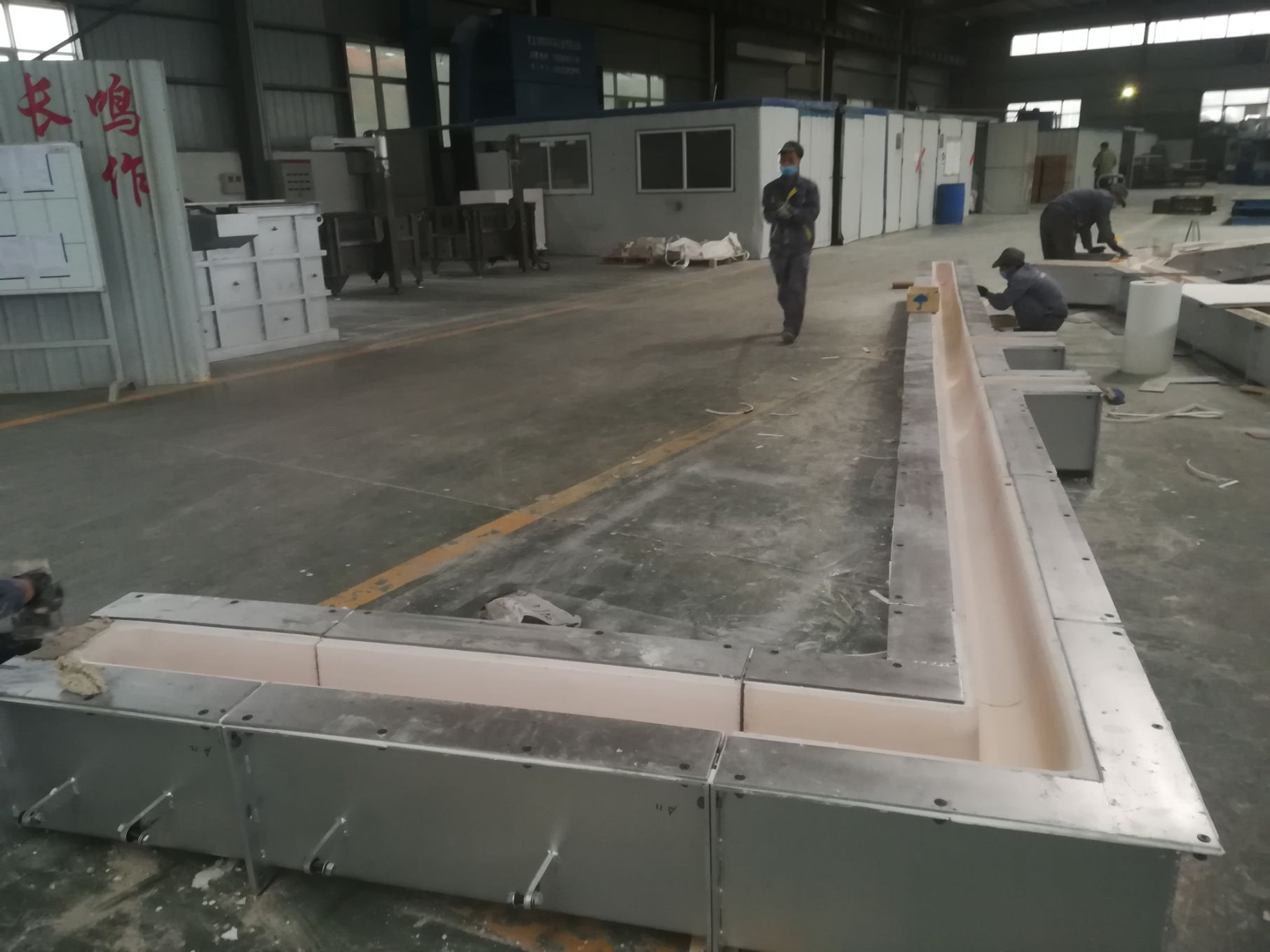

26 Oct Molten Aluminium Trough

Molten Aluminium Trough transports molten alloy from one location to another.

The system usually includes hot-face refractories, spare insulation materials, steel structures, gates and other high-temperature equipment such as thermocouples and gaskets.

They are most commonly used to transport metal from melting furnaces to holding furnaces, from holding furnaces to casting stations, or to transport metals to online degassing and filtration systems.

An effective tank system helps maintain the metal temperature and prevents oxide buildup.

In foundries, tanks are usually used to transport metal from the melting furnace to the holding furnace. The shape and size of the trough system can vary, but it is usually composed of a refractory surface lining and an insulating layer remaining in the steel shell. The aluminium trough design must consider the metal speed, the metal temperature at the casting station (temperature loss due to the distance from the casting station), the specific alloy to be cast, and other variables.

Used to transport molten metal. We can provide one-stop, one-stop solutions. We manufacture our own materials and provide molds according to your shape design.

We also have on-site firing capabilities up to 2450°F. Our trough can be designed for low thermal expansion, low thermal conductivity, wear resistance or non-wetting characteristics.

Before and after firing, we will manually inspect all prefabricated Molten Aluminium Trough to ensure the highest quality. If you need, our trunking material can include stainless steel fiber/needle. We provide a complete internal casting product line through the Christy Cast casting product line. We also have a lot of experience in handling materials from most other major manufacturers. Each of our castings is tested by our internal quality control laboratory, which can complete many ASTM physical performance tests. The laboratory can assure you or your customers that the material meets all your specifications.

AdTech provides a complete turnkey slot system solution

Thermal calculation and engineering design

Refractory selection and recommendations

Finite element analysis

Project management

Professional installation

Electrical engineering, control design and troubleshooting

Sorry, the comment form is closed at this time.