17 Nov Molten Aluminum Filter Aml Spain Foundry

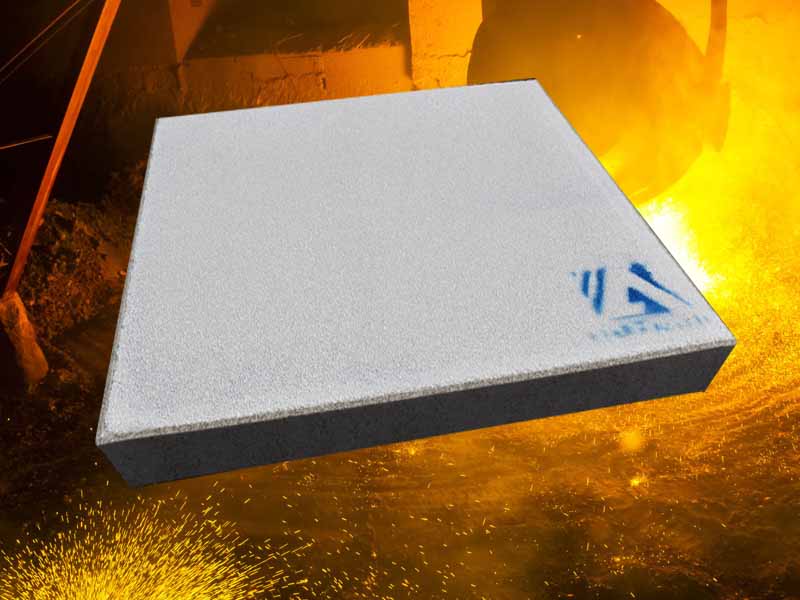

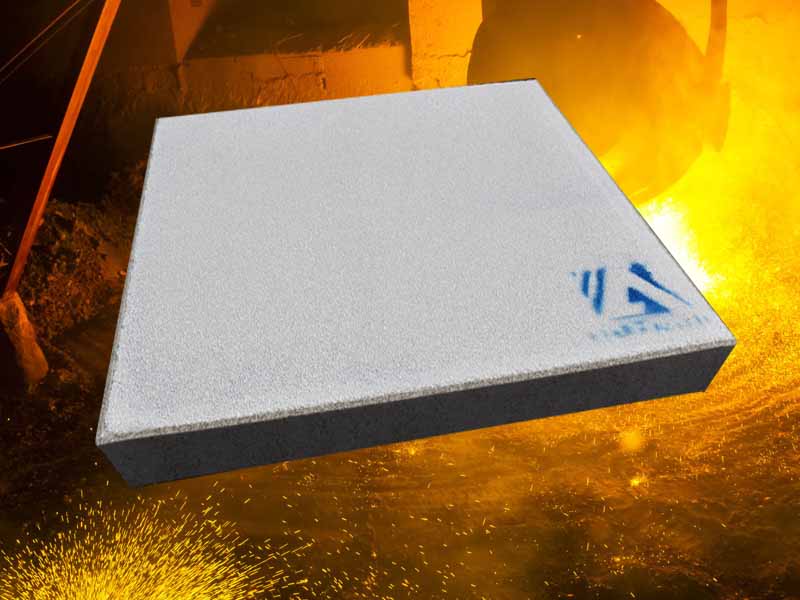

Molten Aluminum Filter Aml Spain Foundry uses a special aluminum ceramic foam filter to remove the inclusions generated between the refining system and the mold table.

The ability of the ceramic foam filter to capture these inclusions is critical to keeping the ingot clean during the metal solidification process. Therefore, the quality and productivity of downstream operations (such as forging, extrusion and rolling) are guaranteed.

Molten Aluminum Filter uses high-quality porous foam and high-purity ceramics as raw materials, which can effectively remove the non-metallic solid mixture of molten aluminum and aluminum alloy melt in your aluminum smelting industry.

Advantages of Molten Aluminum Filter

Uniform opening, high porosity, sufficient sintering, high bending and compressive strength, and good filtering effect.

Liquid aluminum filtration has surface filtration and internal filtration. Surface filtration means that solid impurities are mainly deposited on the surface of the filter medium. Internal filtration refers to the flow of molten aluminum inclusions through the tortuous channels and pores of the filter medium.

Directly block, adsorb, deposit, etc., collide with the hole wall, and firmly stick to the hole wall. As the filtration progresses, the effective filtration section of the pores gradually decreases, the permeability decreases, and the filtration accuracy improves. The ceramic filter supplier internally filters.

Spanish and European foundries purchased Molten Aluminum Filter Aml Spain Foundry through sales@adtechamm.com.

Continuously successful Hertwich continuous homogenization technology Exlabesa of Spain adopted a Hertwich continuous homogenizer to transform its melting and casting workshop in A Coruña.

Spain Exlabesa Extrusion Padron SL has ordered a continuous homogenizing furnace from SMS group’s Hertwich engineering company for its extrusion plant in A Coruña, which is equipped with an air cooling station and a long ingot stacker , Ingot sawing machine, semi-automatic strapping machine and automatic weighing device. The equipment is scheduled to start production at the end of 2018.

The plant produces extruded profiles for automotive, electrical and industrial applications. With the help of the aforementioned project investment, it will improve and optimize its existing homogenizing equipment. The new continuous homogenizer will replace several old batch homogenizers.

Exlabesa will benefit from the new homogenization process in several ways. During heating, holding and cooling, precise and uniform temperature control ensures constant and optimized metallurgical performance.

Integrating all processes in a continuous and fully automated process until the final product is ready for shipment can achieve important and reasonable results.

The final result is that the tested and tested homogenization furnace design greatly reduces energy consumption and heat treatment time.

Hertwich has provided nearly 130 continuous homogenizers so far.

The annual design output of the continuous homogenizing furnace using gas is 32,000 tons of aluminum ingots.

The diameter of the aluminum ingot is 178-406 mm and the length is 6,500 mm.

First place the aluminum ingot in front of the furnace, and then evenly put it in the furnace. The operation of the furnace can be flexibly controlled by heating, aluminum ingot transportation and required holding time.

The heating process can ensure that the entire length of the aluminum ingot is uniformly heated.

After the aluminum ingot passes through the heating and heat preservation section, it enters the air cooling station.

An aluminum ingot sawing machine is installed after the air cooling station, which can cut the head and tail and cut to length. Long ingots from 4,800 mm to 6,500 mm will be automatically stacked, semi-automatically bundled and weighed. All these processes will be integrated in the automatic program along with the necessary transportation.

Traducción Española

Éxito continuo de la tecnología de homogeneización continua de Hertwich Exlabesa de España adoptó el homogeneizador continuo de Hertwich para transformar su taller de fundición y colada en A Coruña.

España Exlabesa Extrusion Padron SL ha encargado un horno de homogeneización en continuo a la ingeniera Hertwich del grupo SMS para su planta de extrusión en A Coruña, que está equipado con una estación de refrigeración por aire y un apillar ling, s flejadora semiautomática y automática. dispositivo de pesaje. Está previsto que el equipo comience a producir a finales de 2018.

La planta produce perfiles extruidos para aplicaciones automotrices, eléctricas e industriales, y con la ayuda de la inversión del proyecto antes mencionado, mejorará y optimizará sus equipos de homogeneización existentes. El nuevo homogeneización existentes. El nuevo homogeneizador ácontinuo sustitus lotes.

Exlabesa se beneficiará del nuevo proceso de homogeneización de varias formas. Durante el calentamiento,

No Comments