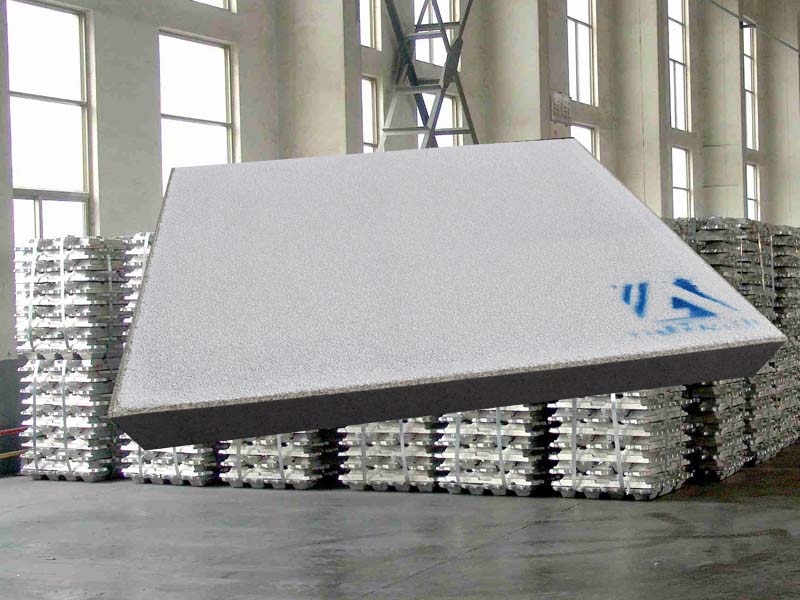

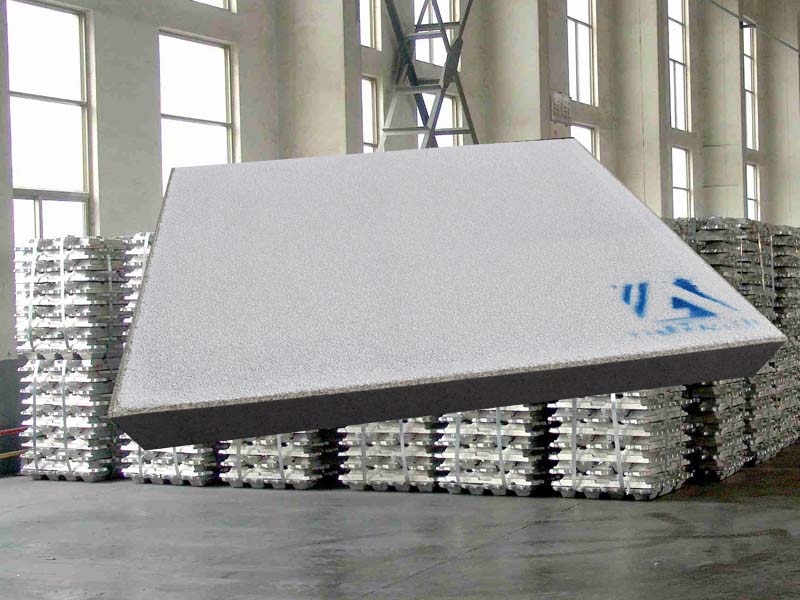

05 1月 Molten ceramic foam filters for Jindal Aluminium

Molten ceramic foam filters Jindal Aluminium is mainly used in foundries and foundries to alumina ceramic foam filters and alloys. The ceramic foam filter has excellent resistance to molten aluminum erosion and corrosion, effectively removing inclusions and reducing trapped gas.

Aluminum alloys are classified into deformed aluminum alloys and cast aluminum alloys according to their uses.

Deformed aluminum alloys include aluminum alloy doors and windows and space shuttle body materials that are used daily. According to different usage requirements, they can be heat treated or not.

The other type is cast aluminum alloys, which mainly include aluminum-silicon alloys, aluminum-copper alloys, aluminum-magnesium alloys, aluminum-zinc alloys and aluminum rare earth alloys.

In the actual production process, cast aluminum alloys are classified according to the content of various chemical elements.

The smelting process needs to increase or decrease the amount of raw materials according to the actual chemical composition. The finished aluminum ingots provided by some manufacturers already contain various alloying elements required for the product. The smelting process basically does not need to add other chemical elements, nor does it need to be directly mixed. There is no smelting sequence, and it is added to molten aluminum. This aluminum alloy is suitable for products with a single structure.

Molten alumina ceramic foam filters Jindal Aluminium is mainly used in foundries and foundries to filter aluminum and alloys. The ceramic foam filter has excellent resistance to molten aluminum erosion and corrosion, effectively removing inclusions and reducing trapped gas.

Using pure aluminum ingots as raw materials, adjust the chemical composition according to actual production requirements. The advantage is that different brands of aluminum alloy liquid can be smelted, which can meet the needs of different products, and the product types are diverse.

Before smelting the aluminum alloy, mix the materials as required. According to the alloy brand, the material needs to consider the burning loss in smelting various elements into new materials, recycled materials, and master alloys.

The more economical and commonly used smelting method in aluminum alloy smelting is gas furnace smelting, which requires fast smelting speed, short time, and low gas consumption.

The order of feeding not only affects the smelting efficiency and the consumption of the alloy but also directly affects the quality of the molten aluminum.

The principle of feeding is first small, then large, first easy to melt and then hard to melt, first to burn less, then easy to burn, and finally spoiled.

First add small pieces of recycled material, low melting point alloying additives (such as Al-Si alloy), and then add a large amount of high melting point aluminum ingots and intermediate alloys (such as Al-Mn), Mg, and other elements to add to the final to burn those easy.

The small pieces of recycled material are first placed on the bottom of the furnace to protect the furnace body and reduce the impact on the furnace wall when large pieces of material are charged. Because of the low melting point of recycled materials, it is easier to melt. It can improve the smelting efficiency and facilitate subsequent smelting of raw materials with higher melting points. Lower the temperature and add Mg to reduce burning loss.

Some domestic automobile auxiliary enterprises use this method when smelting aluminum alloy: preheat the melting furnace first, and start charging after reaching a predetermined temperature, first add small pieces at the bottom of the charge, and then add large aluminum ingots. After adding the burned elements, they are pressurized to melt them directly into molten aluminum.

Aluminum alloy filtration improves the quality of aluminum wheel castings, avoids defects such as slag inclusion and pores, and improves ductility.

No Comments