20 10月 Molten Aluminum Filter Kmc Aluminum

Molten Aluminum Filter Kmc Aluminum is installed in the CFF device and is used for filtering and purifying the smelting aluminium. The aluminum and aluminum alloy are sent to the hot top casting platform through the launder. Casting machines produce various aluminum rods.

Kmc Aluminum purchases filter castings through sales@adtechamm.com and provides the following advantages

1. The filter has excellent corrosion resistance and molten aluminum corrosion ability, which can effectively remove inclusions.

2. Reduce residual gas, provide laminar flow, and the filtered metal becomes quite clean.

3. Cleaner metals can produce higher quality castings.

4. Fewer waste products and fewer inclusion defects, all of which help increase profits.

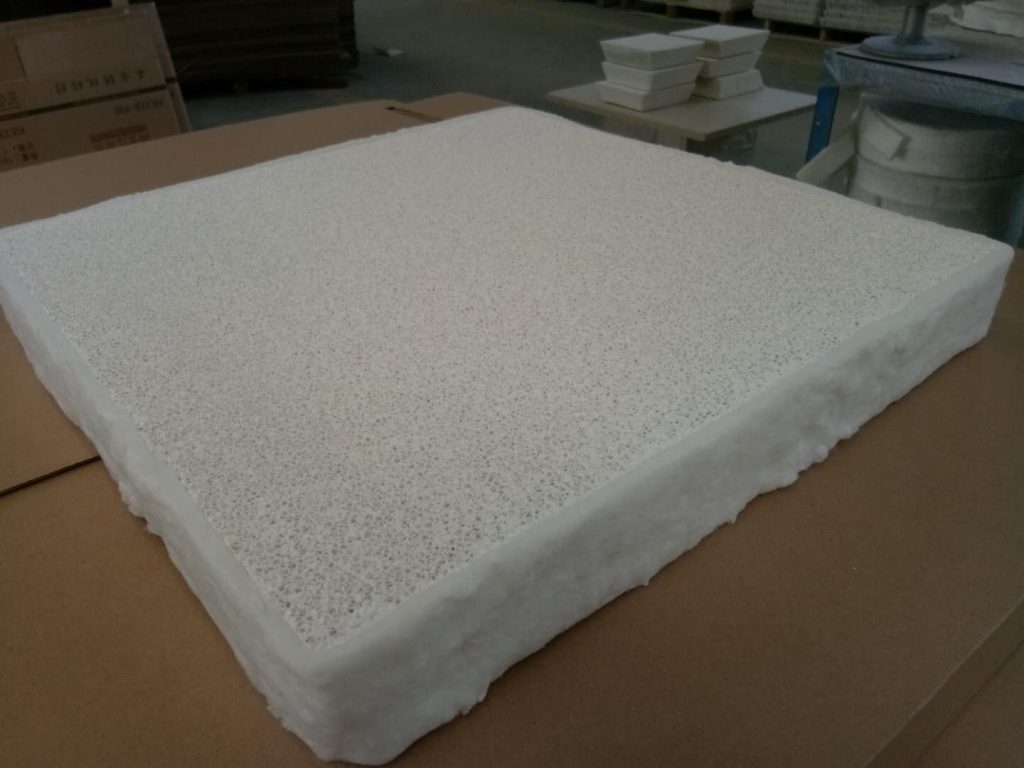

Molten Aluminum Filter Kmc Aluminum is made of non-stick aluminum material, and the product is white or milky white. It is suitable for the purification process of producing aluminum and aluminum alloys with high quality requirements.

Through physical adsorption and chemical action, it can effectively remove various oxidized inclusions produced in the aluminum smelting process, thereby reducing casting defects and improving casting quality.

Foam filter manufacturer reminder

It must be preheated before use, the filter plate must be completely sealed in the aluminum water filter box to ensure that all aluminum water passes through the filter plate, and the total amount of filtration should not exceed the prescribed limit. If it is higher, it must be adjusted by multi-stage filtering or by reducing throughput.

Chinese foam ceramic filter manufacturer can provide 50,000 pieces of ceramic foam filter per month. If you need, please contact sales@adtechamm.com to get the quotation and delivery date of the Chinese supplier.

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

1. Use 10-25ppi for casting

2. Choose 30-60ppi for semi-continuous casting, and choose 50, 60ppi for high-quality aluminum profiles or plates.

3. Use 50-60ppi for continuous casting and rolling

The successful acquisition of Novelis in 2007 enabled Hindalco Industries to become the world’s top five largest hardware specialty in aluminum rolling and has a presence in 11 countries and outside of India. Alcan’s per capita acquisition of a 45 percent stake in the Utkal alumina project, thereby making the project owner Hindalco Industries 100 percent. In 2006, Hindalco Industries announced a 10:1 stock split. Each share with face value rupee. Each share is divided into 10 shares of 1 with a par value of 10 Re per share. Hindalco Industries has completed the largest human rights issue in the history of India’s capital market with a total scale of rupee. 222.66 million US dollars. The stock issuance and listed company was subsequently listed on the Aditya Birla Minerals Australian Stock Exchange. Signed a memorandum of understanding with the government of a new aluminum smelter in the Xiti District of Madhya Pradesh. A joint venture of high-strength aluminum alloy manufacturing in aerospace applications, sporting goods and water and land transportation industries with Almex USA. In 2005, all Indal companies, except for the Kollur aluminum foil factory, merged with Hindalco Industrial Co., Ltd. and Andhra Pradesh. The state governments of Odisha and Jharkhand signed the memorandum of understanding set up new alumina refining, smelting and power plants. Expand the commissioned copper to a total capacity of 500,000 tons.

No Comments