20 10月 Molten Aluminum Filter Korba Aluminium

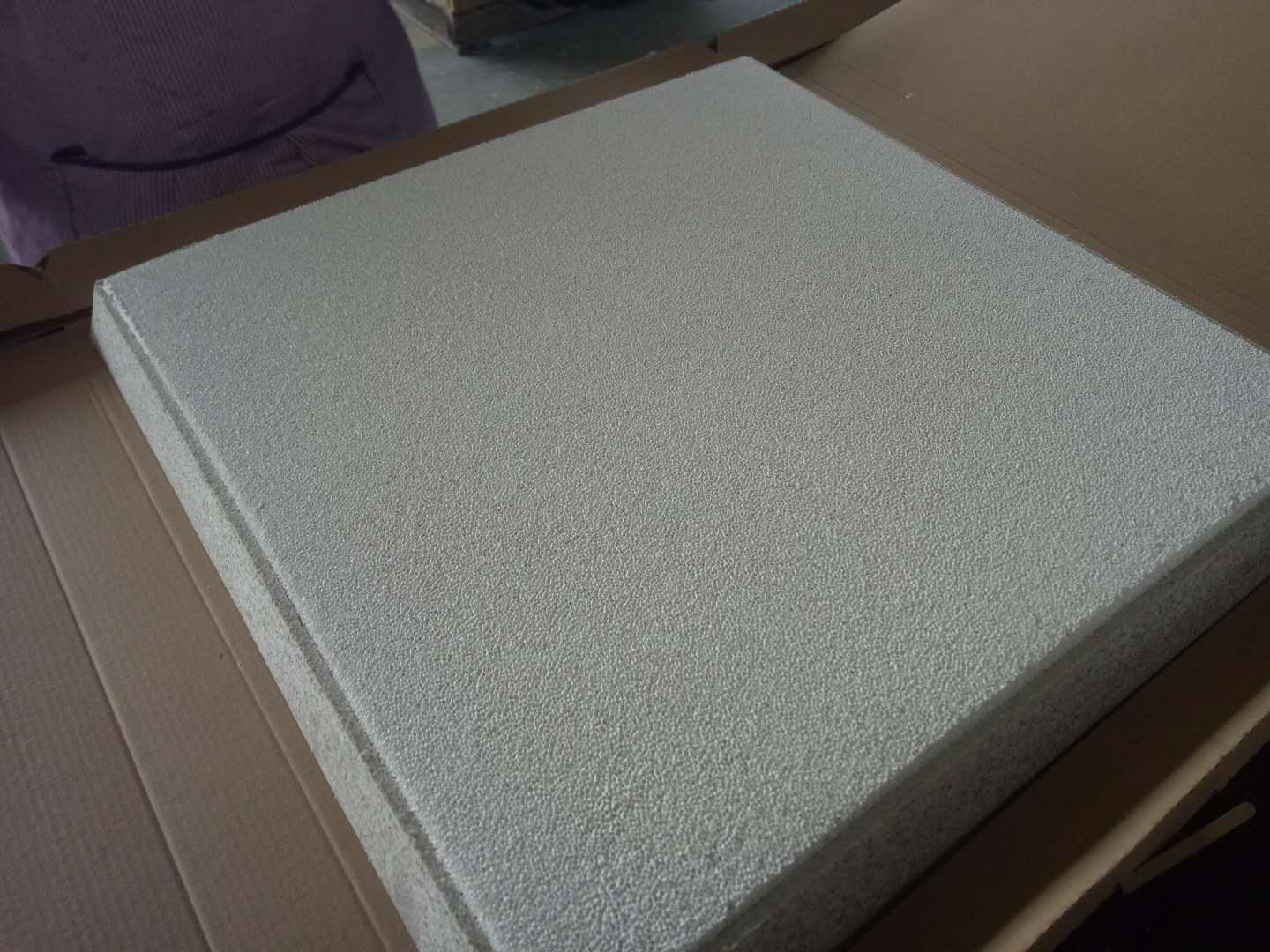

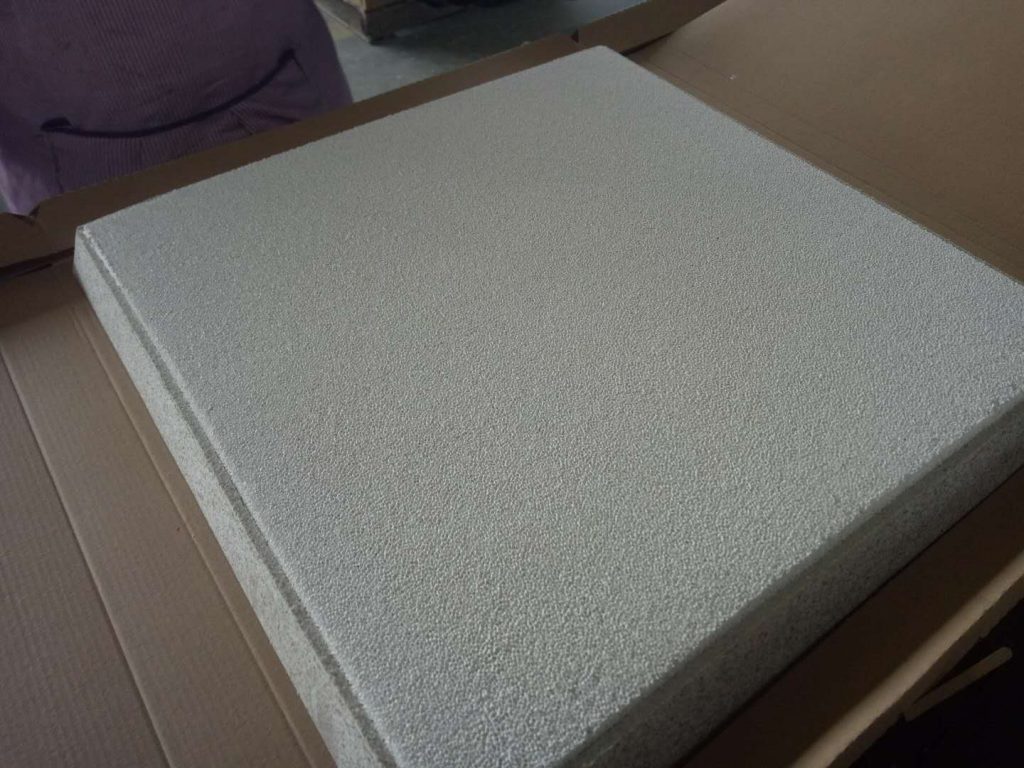

Molten Aluminum Filter Korba Aluminium is a particularly effective and long-lasting liquid aluminum filter for filtering oxide and non-oxide impurities in molten aluminum.

The solid non-metallic particles suspended in the molten metal can cause serious difficulties in the aluminum casting and manufacturing process.

These particles are mainly composed of oxides, which enter the melt together with the waste during the melting process, or are directly oxidized together with oxidizing gases such as air, water vapor, and carbon dioxide when the metal is processed in the molten state. ..

The finely divided oxide films that are stirred into the molten metal are particularly harmful because, compared to macroscopic oxides and other solid particles, they cannot be skimmed off as aggregates and remain suspended in the molten metal.

It has been proposed that these oxide particles impart buoyancy through tiny hydrogen bubbles adsorbed on the particles.

Although this proposal and other predictions about any relationship between hydrogen and particulate solids in the melt lack experimental evidence, the established fact is that there is indeed a relationship between particulate solids and hydrogen during metal casting. Dialogue between.

The solid particles dispersed in the metal act as a nucleus, forming hydrogen bubbles during the solidification of the metal.

In addition, these non-metallic impurities can be used as stress intensifiers and severely damage the mechanical properties of the cast metal.

In addition, non-metallic impurities cause difficulties in the production of aluminum. Alloys, such as those used in die-casting processes, can exhibit excessive tool wear and surface defects in rolled or extruded products.

Molten Aluminum Filter Korba Aluminium is used in the melting and filtering process of aluminum scrap, please contact sales@adtechamm.com.

There are generally two methods for smelting scrap aluminum.

Smelled twice

1. Melt scrap aluminum into ingots (recycled ingots) and stack them according to chemical composition.

2. During smelting, the recycled steel ingots are mixed in the furnace to smelt the finished product.

Analysis and prevention of defects caused by melting

Pinhole

Causes of pinhole defects in aluminum alloys

1. The charge and smelting equipment are not completely baked.

2. The melting temperature is too high or the melting time is too long.

3. The residual time of molten aluminum is very long after degradation.

4. The alloy refinement is not good.

5. The workplace is too humid.

Precaution

1. The charge and equipment must be thoroughly dried.

2. Control the melting temperature, generally not more than 7400C, not more than the pouring temperature, and prevent the alloy from overheating locally during the melting process.

3. The operation speed is fast and the melting time is as short as possible.

4. Be careful in refining operations, refining is the best way to prevent stoma.

5. The alloy liquid should be poured out in time 8-15 minutes after modification; keep the melting point dry.

Oxidation slag

Analysis on the Causes of Aluminum Alloy Oxidation and Slag Inclusion Defects

1. The fee is not clear, and the refund amount is too high.

2. The slag in the alloy liquid is not removed.

3. After the healing deteriorates, the rest time is not enough.

Precaution

After the charge is polished, the return charge is controlled within 70% of the charge quality.

Degas and remove slag thoroughly; after the screed, there must be enough standing time to allow enough time for the slag to sink or float.

After Atlas Aluminum proposed to produce aluminum ingots in Pakistan, the government has allowed it to import industrial aluminum scrap requests. Atlas Aluminum is headquartered in Karachi (Pakistan’s largest city), and recently negotiated with the commercial department on the import of harmless aluminum scrap. The company has established an efficient and environmentally friendly factory that gathers advanced technologies in the industry to produce aluminum ingots.

According to the “Basel Convention” for the definition and regulations of hazardous waste, the import of waste slag, waste ash, residues, etc. containing metals, arsenic and its compounds (including aluminum) is prohibited.

Aluminum is often used in industries such as food packaging, doors and windows, curtain walls, and auto parts. On the one hand, prohibiting the import of hazardous waste can protect the environment; on the other hand, the use of imported waste can greatly reduce the price of raw materials and increase the competitive advantage of value-added industries.

Atlas Aluminum’s request was forwarded to the Ministry of Climate Change. This department is mainly responsible for implementing the control of the cross-border flow of hazardous waste and the implementation of the Basel Convention. The Ministry of Climate Change pointed out that aluminum scrap is in category B in the Basel Convention and is not a restricted category.

No Comments