21 10月 Molten Aluminum Filter Sual

Molten Aluminum Filter Sual adopts a three-dimensional network structure and uses organic bubbles communicating with pores as a carrier to filter and purify molten aluminum.

It is embedded in a special molten material suspension with thixotropy, and the suspension is evenly coated on the bubble frame of the carrier, sintered and solidified at a high temperature of 1680°C.

The ceramic foam filter is installed in the aluminum alloy liquid filter body to provide high value-added, high-tech aluminum alloy precision casting performance for aviation and transportation. Such as: computer hard disk, aluminum foil micron cotton, printed polystyrene base, cans, jet turbofan blades and other products.

The quality of the aluminum melt is very important and has a great influence on the subsequent process performance and the quality of the final product. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution.

1. During the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic materials. .slag. (For example, lining fragments, chlorides and carbides in flux, etc.), and large intermetallic particles, etc.

2. Part of the waste in the combined charge contains some non-aluminum impurities during the recycling process. Because the waste comes from process waste and waste from various processes in the plant, as well as waste outside the plant, the route is different, the composition is complex, and the quality is poor.

These impurities are easy to produce bubbles and inclusions in the slab, which seriously affect the purity of the molten metal, and then affect the processing performance, mechanical properties, corrosion resistance and product appearance.

Therefore, Molten Aluminum Filter Sual is very necessary for the purification of aluminum melt.

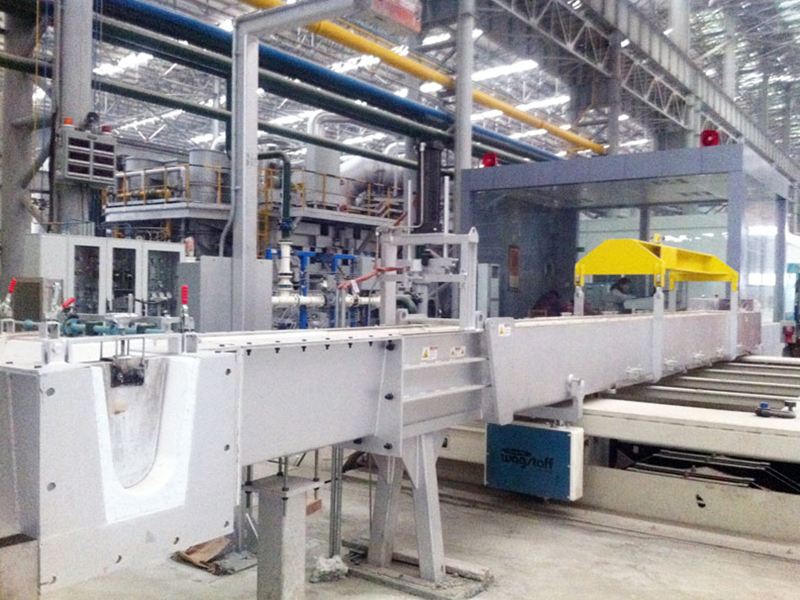

Ceramic sink is an important part of aluminum and aluminum alloy casting process. In most cases, it is installed between the furnace and the casting platform, as well as on the casting platform. The main function is to discharge aluminum melt.

The flow cell is installed between the furnace and the casting platform, wrapped with a metal (mainly iron) jacket, and lined with thick silicate fiber paper to ensure that the flow cell does not directly contact the iron sleeve and break easily. …Plays a very good insulation effect on molten aluminum.

When installed, it is set at a suitable slope, and the molten aluminum flows by gravity.

The molten aluminum flows directly from the ears of the furnace, is transported to the casting machine platform through the chute, and then diverted to the separation plate through the upper chute of the casting machine, and then flows into the separation plate. The mold is finally cooled and crystallized into a finished aluminum rod.

A filter box is often installed at the distance between the smelting furnace and the platform where the molten aluminum is transported, and a ceramic filter plate is placed on the filter box to filter the molten slag in the molten aluminum.

However, due to the large area of the ceramic filter plate and the large number of through holes (80%-90%), the aluminum liquid cannot completely cover the surface when passing through the filter plate, but simply passes through the specific filter surface. And cause the filter to become clogged. The filter plate is broken, which affects the production of aluminum castings.

The launder with the function of lifting molten aluminum is located behind the filter box. When the aluminum liquid flows through the filter plate in the filter housing, it is responsible for raising the filtered aluminum liquid to the height before filtering, so as to ensure the uniform and complete passage of the aluminum liquid. The surface of the filter plate is used to filter and purify molten aluminum.

RUSAL announced that group members have entered into a contract with En+’s contacts. Under the contract, En+’s contact, KraMZ Ltd., agreed to purchase aluminum (experimental shapes) from group members (“New Aluminum Sales Contract”).

According to the new aluminum sales contract and the previously disclosed aluminum sales contract terms, the total annual transaction amount payable by En+’s associates to the group for the fiscal year ending December 31, 2021 is estimated to be approximately US$1544.6 million.

The test profiles are left after the test of the test profile manufacturing. These test profiles are not used in the group’s further manufacturing process, so they are provided to a number of potential customers who are interested in such aluminum products for purchase. KraMZ Ltd. is the buyer who agreed to purchase.

No Comments