23 11月 Molten Aluminum Purify

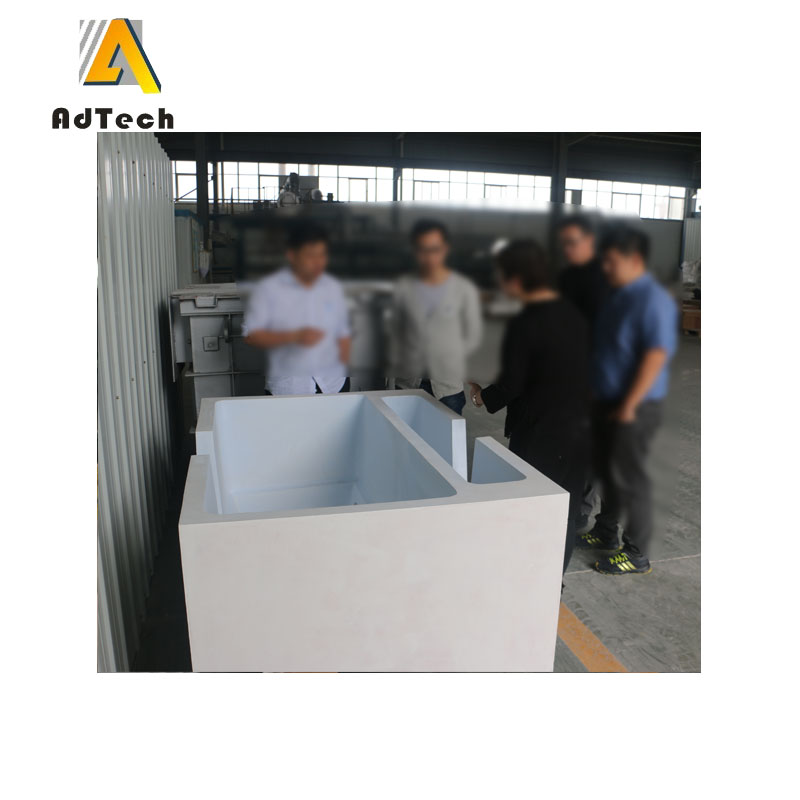

Molten Aluminum Purify is usually installed between the furnace discharge port and the filter box.

The melt flows into the box of the degassing device, and the inert gas is broken by rotating the rotor to form a large number of dispersed bubbles into the aluminum melt.

After collision, capture, surface adsorption and partial pressure, the hydrogen and oxidized slag in the melt are taken out of the aluminum liquid surface with the gas floating to form scum, and the aluminum alloy melt flows out from the outlet of the degassing device, that is, continuous online Purpose of refining.

The on-line rotor degassing device is based on absorbing the advantages of the mainstream box-type degassing device in the market. It has improved many key technologies such as box sealing and anti-turbulence on the surface of the aluminum liquid, ensuring the high efficiency, continuous stability and low cost of the degassing device. Run.

Features of Molten Aluminum Purify

• High degassing efficiency can reach more than 60%

– The dispersion of the process gas in the melt is optimized;

– The largest contact area and contact time between dispersed bubbles and melt;

– The box is completely sealed to ensure a stable inert gas environment;

– The surface of the melt is stable and there is no turbulence effect.

• Simple installation and maintenance. The inner lining of the pre-fired forming degassing box is easy to replace, which reduces the production downtime to a minimum.

• Long component life and low maintenance and operation costs.

– The service life of heater and heater protection tube is more than 3 months;

– The life of the cabinet is more than 1 year;

– The life span of the rotor and shaft is more than 3 months;

– The rotor is not used to rotate the main shaft to cool the gas.

• Solve the problem of excessive aluminum in the cabinet.

– Optional integral tiltable degassing device, which can be tilted at a specific time before the end of casting, and the aluminum liquid stored in the box is completely poured into the launder to complete the casting. Solve the problem of aluminum cabinet memory.

Maintenance of degassing tank

1.During continuous casting, clean up the scum on the surface of the molten aluminum in the degassing tank every two days: stop the heater, lift the cover of the degassing tank and move it to the side, use a shovel to remove the scum on the surface of the molten aluminum Then, quickly close the degassing box cover. After the box cover is in the correct position, start the heater.

2. When replacing the alloy, first lift the degassing tank cover, after cleaning the scum on the surface of the molten aluminum, place the degassing tank cover, start the heater, and then put the molten aluminum in the tank.

3. If the deaeration box is not used for a long time, the deaeration box should be cleaned: lift the deaeration box cover and move it aside. First clean up the scum on the surface of the molten aluminum, and then drain the molten aluminum. Clean up after the temperature in the box decreases. After cleaning, be sure to paint in the box.

4. Matters needing attention

4.1 When cleaning the scum on the surface of the molten aluminum, you must pay attention to safety to prevent being injured by the high-temperature molten aluminum.

4.2 Before the molten aluminum in the degassing tank is discharged, the scum on the surface of the molten aluminum must be cleaned. If the slag is not cleared first, the slag will be deposited on the bottom, which is difficult to remove. After a long time, it will damage the heater and rotor.

4.3 In short, it is necessary to clean the slag first and then put the molten aluminum!

Sorry, the comment form is closed at this time.