19 9月 Molten Metal Launder

Molten Metal Launder

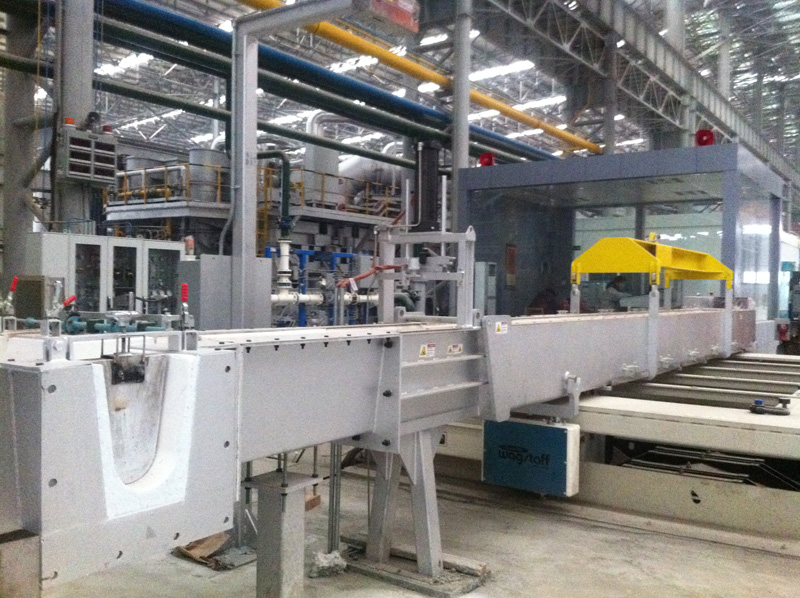

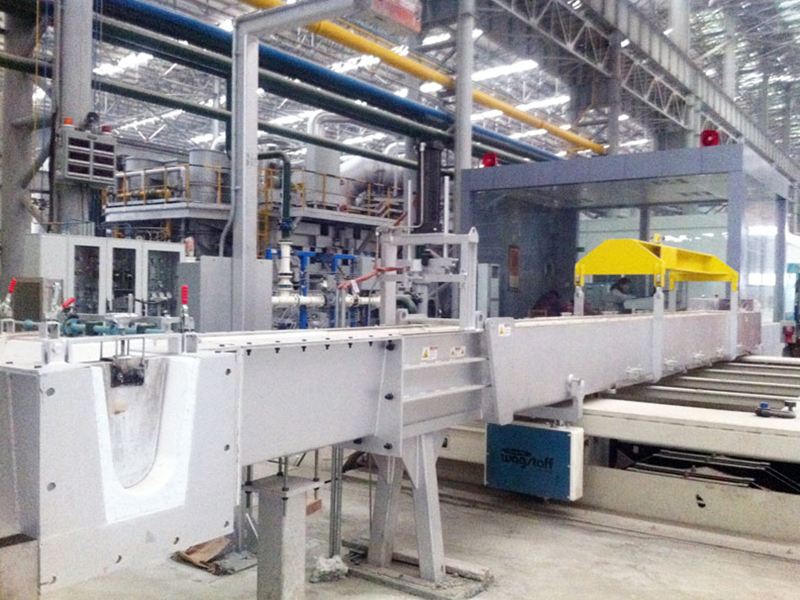

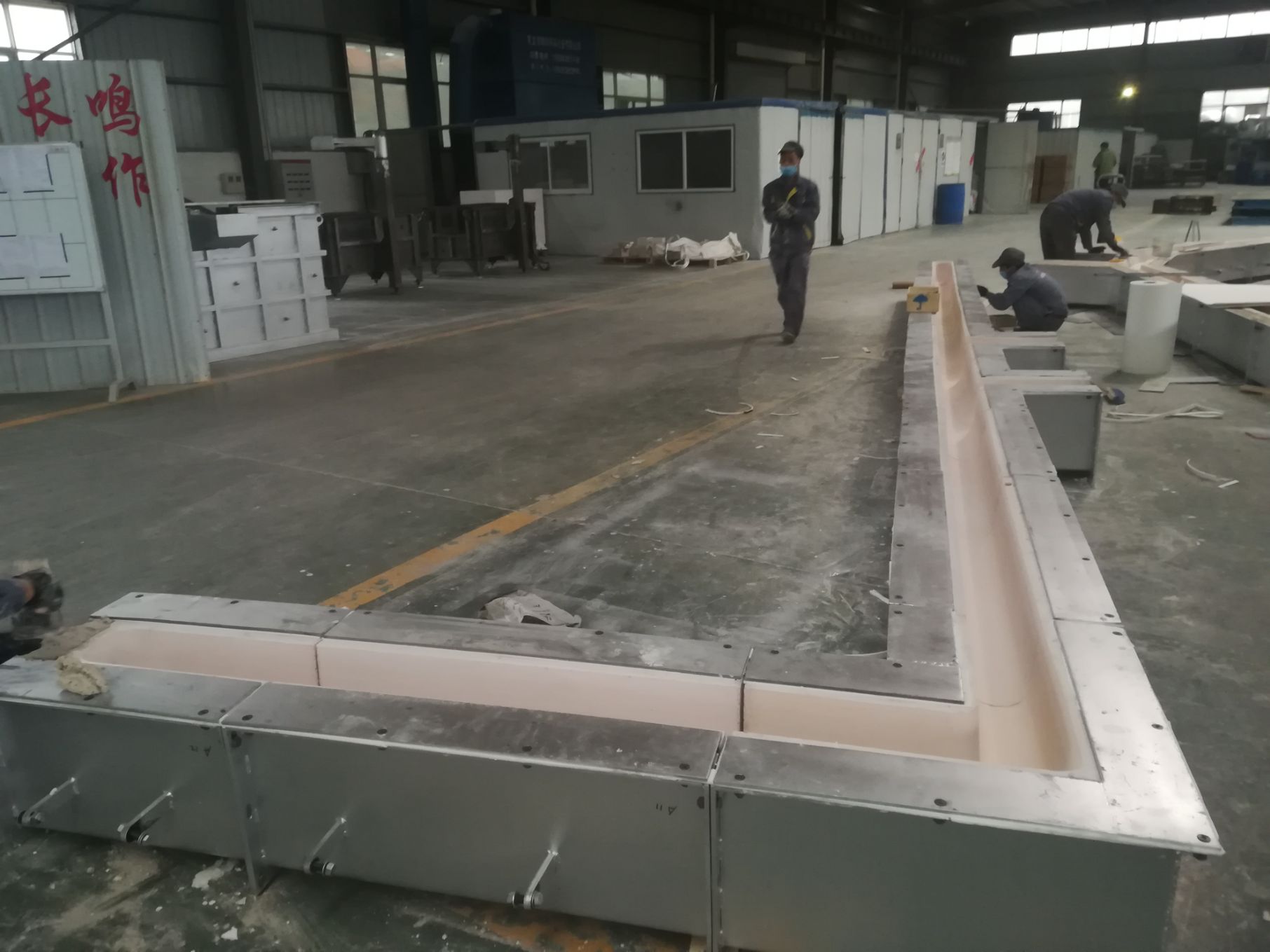

Molten Metal Launder from AdTech is the integrated launder unit manufacturer which is specialized in the development of new material and production of high-performance insulation sealing. Since 2012, our company has started to R&D overall launder, degassing unit and plate filtration unit. Supply integration services in high-precision aluminum alloy casting. Got good reputation in market.

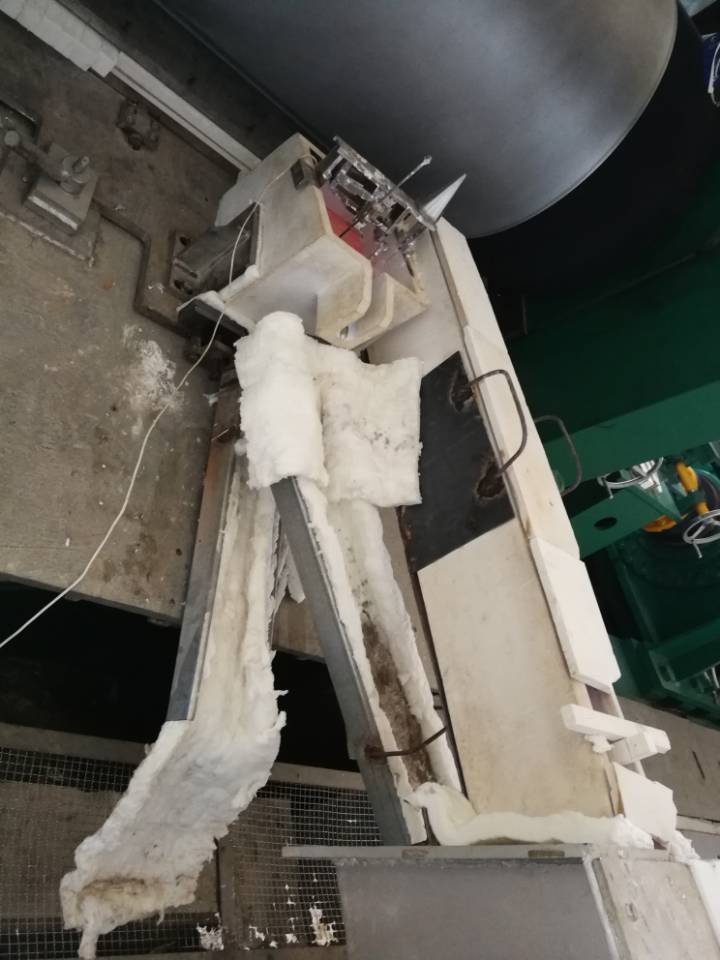

Molten Metal Launder has the long lifetime lining. Use new high-silicon melting material which is corrosion resistance, non-stick molten aluminum, non-polluting to molten aluminum. Can meet the high value-added, high-tech performance aluminum casting requirement.

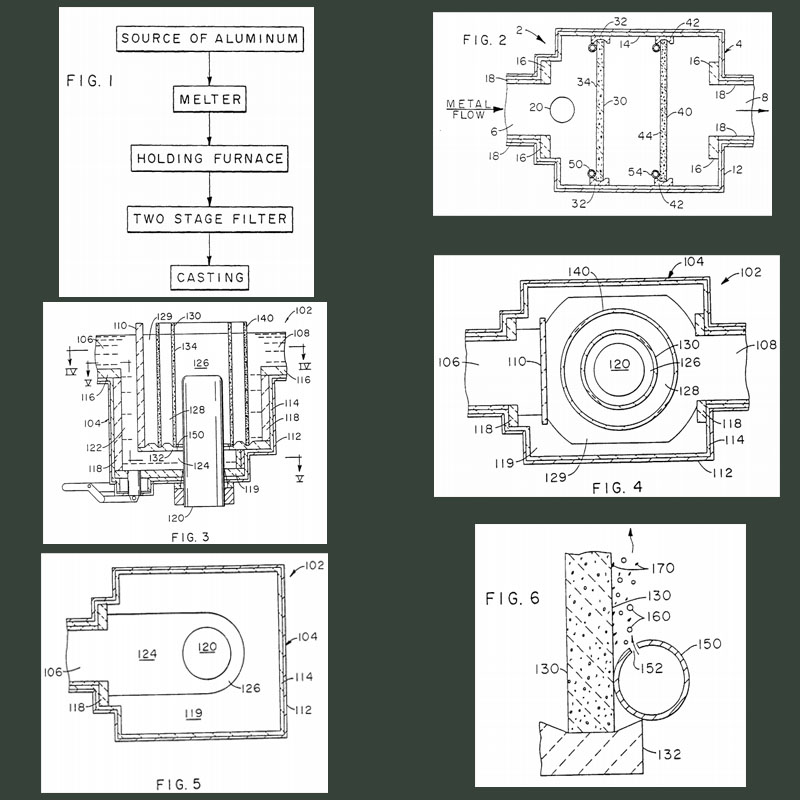

Molten Metal Launder is installed between the furnace and the casting machine and it has dual function: transportation and insulation. Mainly used in the transportation of molten aluminum between furnace, purifying furnace, casting platform, degassing unit and filtrating unit for the aluminum precision casting. It is suitable for casting such aluminum materials as below stated: computer hard drive, micron-grade aluminum foil, PS board, canning materials, fan blades of jet turbine engine, etc.

Advantages for Molten Metal Launder:

Good thermal insulation property and reasonable design can prolong service life.

Formed by high silicon melting material, high precision dimensions.

High strength, erosion resistance, impact resistance, good thermal shock resistance and smooth surface.

Strong corrosion resistance to aluminum alloy, enhance the effect of equipment, prolong lifetime for casting special alloy.

The molten aluminum temperature drops within 2℃ per meter in the process of using the launder.

Easy Flow Molten Metal Launder Instructions:

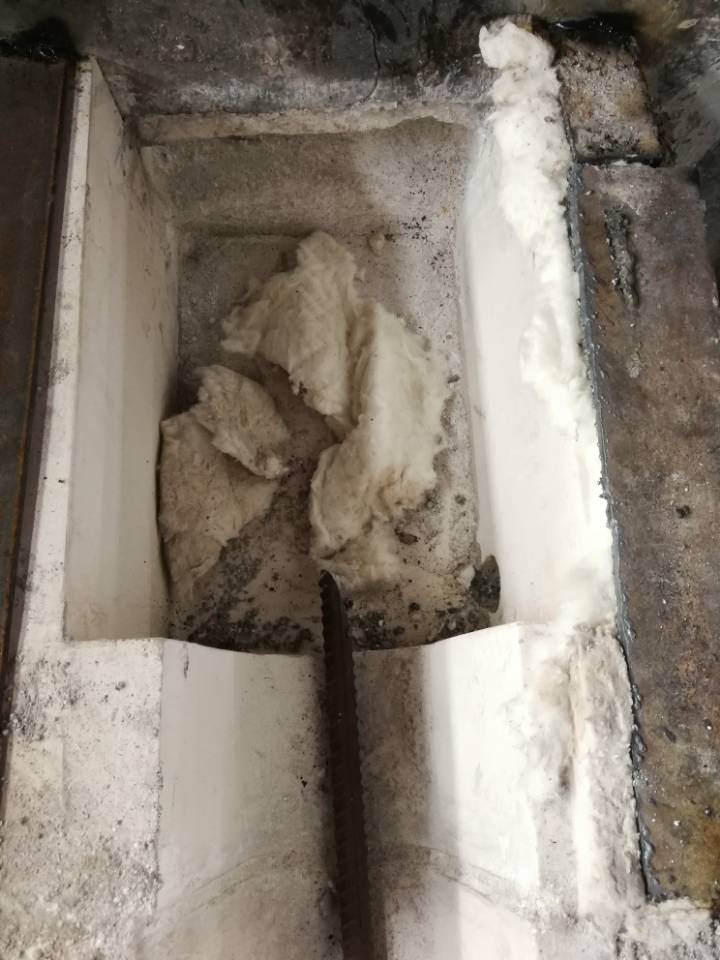

Molten Metal Launder as drawing, keep the launder clean, avoid breakage and gap.

Preheat the installed launder averagely, warm up 6-8 hours, check the lining surface (below 800 degrees), get rid of adsorbed crystal water, use it safely and effectively.

If electric heating not available, heat it by flame is recommended. The key is to control the flame temperature and to avoid direct fire cause the lining body, disk or ceramic foam filters cracked. There are three kinds of Flame, red weak flame, yellow medium flame, blue strong flame.

No Comments