Posted at 01:46h

in

Ceramic Foam Filter

by admin

Metallurgical and foundry filters for aluminum refining

PURPOSE: Filter elements for aluminum PEA are designed for fine filtering of all grades of aluminum and its alloys (wrought and cast alloys based on aluminum - silicon (silumins), aluminum - copper (duralumin), aluminum - magnesium (magnalium), special silumin) zinc , magnesium and other non-ferrous metals and alloys, as well as providing additional positive effects on aluminum melts at the request of the Customer.

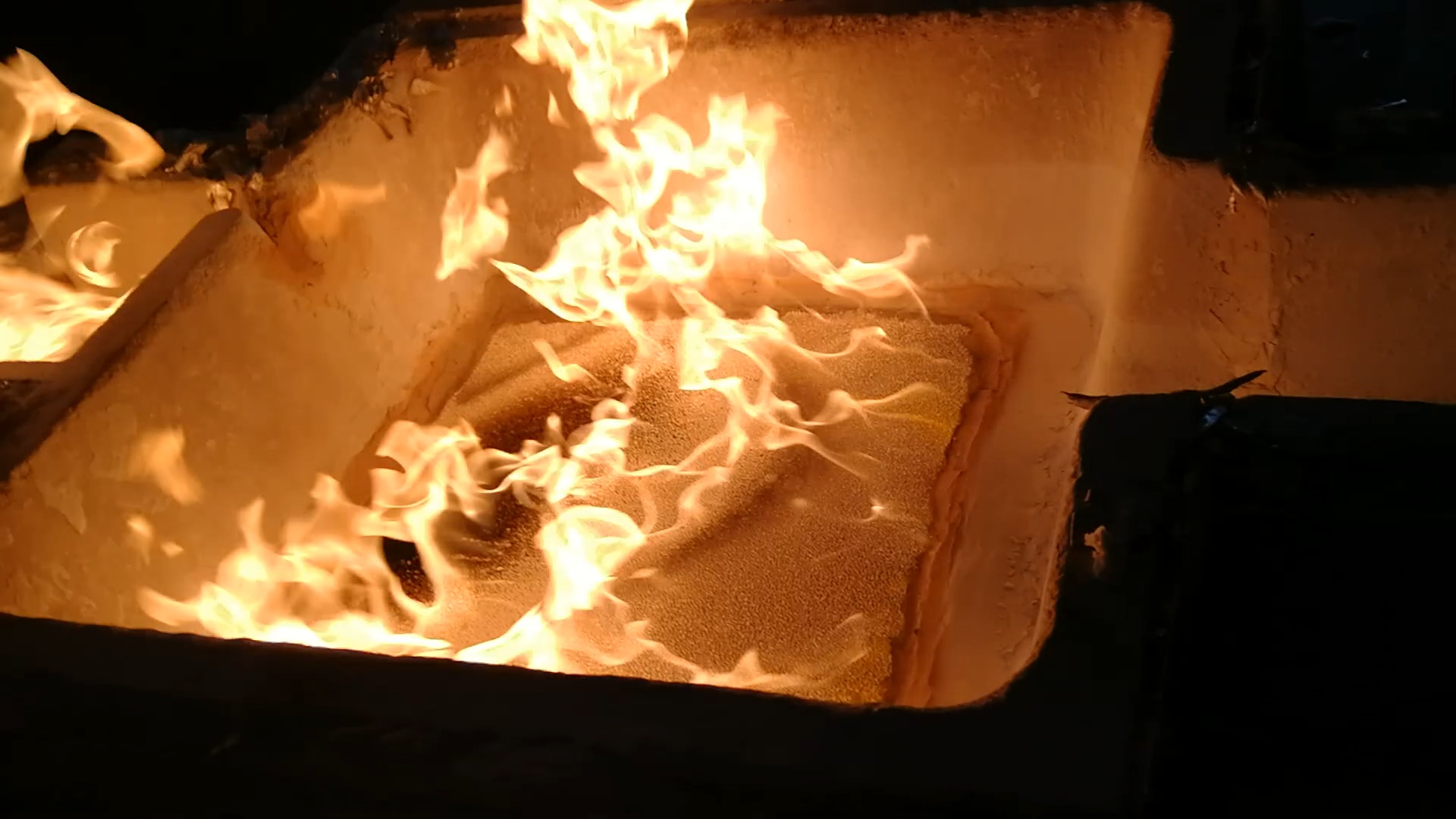

DESCRIPTION: Filter elements for aluminum FEA are made on the basis of a glass mesh of the brand KS-11-LA or SSF by dipping fiberglass in a special solution, subsequent drying and calcination at temperatures above 600 ºС. This treatment gives the glass mesh rigidity, modifying ability and chemical resistance under the influence of liquid non-ferrous metals alloys with temperatures up to 800 ºС and working time up to 200 s. The filter base is a mesh structure with a surface density of 500 ... 600 g / m2 and filter mesh sizes: 1.0x1.0mm; 1.5x1.5mm; 2.0x2.0mm (1.5mm recommended), filter thickness - 0.8 ... 1.2 mm. Filters for alloys based on aluminum FEA are supplied in the form of rolls or cut into rectangles of the required sizes (special shape - circle, volume funnel, etc. - as agreed with the manufacturer).

APPLICATION TECHNOLOGY: Filter elements for FEA aluminum are used in the production of color castings in single sand molds and chill molds. To obtain the maximum filtering effect, the filter should be installed as close as possible to the body of the casting. Filters can also be used in the production of investment castings (precision casting), injection molding, and can also be installed in filtration boxes as a high-yield metallurgical filter when pouring metal from the furnace into the intermediate transport bucket (or from the intermediate ladle to the mixer). The shape and dimensions of the filter must correspond to its purpose and are calculated according to the methods based on the specific technological conditions for the production of castings. If in doubt when choosing a size, contact the manufacturer’s technology department.

SCIENTIFIC BASES OF EFFICIENCY: The introduction of special components into the filter impregnation composition gives the silica mesh a modifying effect (at the request of the customer), enhanced refining and

degassing ability, increased resistance to high temperatures and other useful properties.

The use of FEA casting filters with a special coating makes it possible to ensure high-quality metal purity with high mechanical characteristics as a result of the following effects on the melt:

fine cleaning of non-ferrous alloys of solid non-metallic impurities and gases due to the implementation of effective filtering mechanisms: mechanical retention of slag inclusions and oxide films with sizes exceeding the cell size, delay of inclusions by the slag layer from the supply side of the filter, including particles of significantly smaller sizes, adsorption of undissolved particles and evolution of dissolved gases as a result of contact of a liquid metal with a filter base and a refractory coating;

modification in silumin of eutectic silicon (eutectic) and alpha solid solution of silicon in aluminum (Al grains), grinding, leveling the structure of color castings as a result of saturation of the melt with effective crystallization, modification centers and alloying elements from the impregnating composition;

the release of inert gases during heating and the use of finely dispersed refractories in the impregnating composition guarantees high thermal and chemical resistance of the filter structure during the entire pouring time, which greatly expands the scope of application of filters based on glass fiber for filtering aluminum-based alloys;

the formation of a laminar metal flow behind the filter contributes to the smooth filling of the mold, while reducing the likelihood of destruction of the mold cavity, as well as the likelihood of the formation of new impurities as a result of reoxidation of the molten metal

EFFECT OF APPLICATION:

a sharp decrease in the number of castings defective due to the presence of non-metallic inclusions, oxide films, slag and gases;

simplification and a significant reduction in the metal consumption of gating systems, as the gating system does not need elements that inhibit the movement of metal and slag traps;

optimization of casting speed, prevention of mold erosion, improvement of surface and quality of castings;

increasing the mechanical properties of the cast structure and achieving better density of castings

ADVANTAGES OF USE:

the variety of execution forms (rectangle, circle, funnel, etc.) allows the use of filter elements instead of expensive ceramic foam, mesh ceramic, chamotte and other filters;

low cost and high quality filtration;

simplicity in technology of use (there are no changes in foundry equipment);

the possibility of using direct technology

[embed]https://www.youtube.com/watch?v=SKW0iofyGko[/embed]

SCIENTIFIC BASES OF EFFICIENCY: The introduction of special components into the filter impregnation composition gives the silica mesh a modifying effect (at the request of the customer), enhanced refining and degassing ability, increased resistance to high temperatures and other useful properties.

The use of FEA casting filters with a special coating makes it possible to ensure high-quality metal purity with high mechanical characteristics as a result of the following effects on the melt:

fine cleaning of non-ferrous alloys of solid non-metallic impurities and gases due to the implementation of effective filtering mechanisms: mechanical retention of slag inclusions and oxide films with sizes exceeding the cell size, delay of inclusions by the slag layer from the supply side of the filter, including particles of significantly smaller sizes, adsorption of undissolved particles and evolution of dissolved gases as a result of contact of a liquid metal with a filter base and a refractory coating;

modification in silumin of eutectic silicon (eutectic) and alpha solid solution of silicon in aluminum (Al grains), grinding, leveling the structure of color castings as a result of saturation of the melt with effective crystallization, modification centers and alloying elements from the impregnating composition;

the release of inert gases during heating and the use of finely dispersed refractories in the impregnating composition guarantees high thermal and chemical resistance of the filter structure during the entire pouring time, which greatly expands the scope of application of filters based on glass fiber for filtering aluminum-based alloys;

the formation of a laminar metal flow behind the filter contributes to the smooth filling of the mold, while reducing the likelihood of destruction of the mold cavity, as well as the likelihood of the formation of new impurities as a result of reoxidation of the molten metal

EFFECT OF APPLICATION:

a sharp decrease in the number of castings defective due to the presence of non-metallic inclusions, oxide films, slag and gases;

simplification and a significant reduction in the metal consumption of gating systems, as the gating system does not need elements that inhibit the movement of metal and slag traps;

optimization of casting speed, prevention of mold erosion, improvement of surface and quality of castings;

increasing the mechanical properties of the cast structure and achieving better density of castings

ADVANTAGES OF USE:

the variety of execution forms (rectangle, circle, funnel, etc.) allows the use of filter elements instead of expensive ceramic foam, mesh ceramic, chamotte and other filters;

low cost and high quality filtration;

simplicity in technology of use (there are no changes in foundry equipment);

the possibility of using direct technology

[embed]https://www.youtube.com/watch?v=SKW0iofyGko[/embed]

SCIENTIFIC BASES OF EFFICIENCY: The introduction of special components into the filter impregnation composition gives the silica mesh a modifying effect (at the request of the customer), enhanced refining and degassing ability, increased resistance to high temperatures and other useful properties.

The use of FEA casting filters with a special coating makes it possible to ensure high-quality metal purity with high mechanical characteristics as a result of the following effects on the melt:

fine cleaning of non-ferrous alloys of solid non-metallic impurities and gases due to the implementation of effective filtering mechanisms: mechanical retention of slag inclusions and oxide films with sizes exceeding the cell size, delay of inclusions by the slag layer from the supply side of the filter, including particles of significantly smaller sizes, adsorption of undissolved particles and evolution of dissolved gases as a result of contact of a liquid metal with a filter base and a refractory coating;

modification in silumin of eutectic silicon (eutectic) and alpha solid solution of silicon in aluminum (Al grains), grinding, leveling the structure of color castings as a result of saturation of the melt with effective crystallization, modification centers and alloying elements from the impregnating composition;

the release of inert gases during heating and the use of finely dispersed refractories in the impregnating composition guarantees high thermal and chemical resistance of the filter structure during the entire pouring time, which greatly expands the scope of application of filters based on glass fiber for filtering aluminum-based alloys;

the formation of a laminar metal flow behind the filter contributes to the smooth filling of the mold, while reducing the likelihood of destruction of the mold cavity, as well as the likelihood of the formation of new impurities as a result of reoxidation of the molten metal

EFFECT OF APPLICATION:

a sharp decrease in the number of castings defective due to the presence of non-metallic inclusions, oxide films, slag and gases;

simplification and a significant reduction in the metal consumption of gating systems, as the gating system does not need elements that inhibit the movement of metal and slag traps;

optimization of casting speed, prevention of mold erosion, improvement of surface and quality of castings;

increasing the mechanical properties of the cast structure and achieving better density of castings

ADVANTAGES OF USE:

the variety of execution forms (rectangle, circle, funnel, etc.) allows the use of filter elements instead of expensive ceramic foam, mesh ceramic, chamotte and other filters;

low cost and high quality filtration;

simplicity in technology of use (there are no changes in foundry equipment);

the possibility of using direct technology

[embed]https://www.youtube.com/watch?v=SKW0iofyGko[/embed]

How the filter works.

There are three main mechanisms of the filtration process by which the filter removes inclusions from molten metal:

Filtration occurs through a combination of three mechanisms: filtering by sieving, filtering by increasing cake, filtering with a deep bed.

Screening is the mechanism by which particles remain on the surface of the filter, since they are larger than the openings of the filter.

Cake filtering occurs when inclusion particles are separated from the molten metal due to the development of a layer or cake (pre-deposited particles). The cake becomes thicker during the filtration process, causing the metal flow to slow down and stop completely over time.

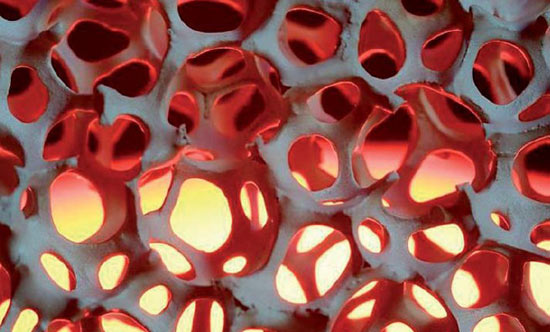

In deep bed filtration, the retained solids are significantly smaller than the pores of the filter. Surface forces cause particles to adhere to the surface of the filter. This mechanism is especially effective with ceramic foam filters due to the tortuous flow path through the filter.

How the filter works.

There are three main mechanisms of the filtration process by which the filter removes inclusions from molten metal:

Filtration occurs through a combination of three mechanisms: filtering by sieving, filtering by increasing cake, filtering with a deep bed.

Screening is the mechanism by which particles remain on the surface of the filter, since they are larger than the openings of the filter.

Cake filtering occurs when inclusion particles are separated from the molten metal due to the development of a layer or cake (pre-deposited particles). The cake becomes thicker during the filtration process, causing the metal flow to slow down and stop completely over time.

In deep bed filtration, the retained solids are significantly smaller than the pores of the filter. Surface forces cause particles to adhere to the surface of the filter. This mechanism is especially effective with ceramic foam filters due to the tortuous flow path through the filter.

Functions

1. The disinfection of melting metal fluid

2. Simplified navigation system

3. Improving the metallurgical structure of castings

4. Reduce stealth castings

5. Improving casting quality

6. Reduction of internal defects of re-oxidation of castings

7. Reduce surface defects after processing castings

Performance and Applications

1. Filter-PAL filter is an alumina ceramic product with a three-dimensional network structure through high temperature sintering

2. High strength, erosion resistance, strong adsorption of impurities, can effectively remove tiny inclusions in molten aluminum

3. Widely used in aluminum foil roll casting blanks, production of aluminum and automotive hubs casting blanks

4. Higher applicability and cost-effectiveness

Information about the company

AdTech manufactures materials and provides services for high temperature filtration and purification with strong technical strength and control system. AdTech is located in Wen County, China, which covers an area of over 20 acres with 20,000 square meters of workshop and warehouse. AdTech serves customers from dozens of countries and regions, including China (China Aluminum Industry, Zhongwang China, Weiqiao, Midas), the Middle East (Bahrain aluminum, Dubai aluminum, Midal cables), Southeast Asia (metal press, GVA, Jindal,) and Europe (hydro, Rusal), etc. AdTech has established long-term relationships with a number of world-famous enterprises. AdTech is a global provider and provider of high-end online degassing and high-temperature filtration and material purification solutions for the high-precision aluminum foundry industry.

Questions and answers

1. Q: Are you a factory or a trading company?

A: we are a factory which was founded in 2012

2. Q: What are your main products?

A: We have been producing online degassing, filtration equipment, ceramic foam filter, hot casting materials, nozzle, Repair coating material and flow abroad for many years.

3. Q: How can you control the quality?

A: For each product processing, we have a complete quality control system for chemical composition and physical properties. After production, all products will be tested, and we have quality certificates with ISO9001 / ISO14001 / SGS.

4. Q: What payment term can you accept?

A: T / T or L / C

5. Q: How can I get samples?

A: We are honored to offer you samples.

6. Question: Does your company accept customization?

A: we accept OEM service.

7. Q: can we visit your company?

A: Yes, of course, you can visit our company.

Functions

1. The disinfection of melting metal fluid

2. Simplified navigation system

3. Improving the metallurgical structure of castings

4. Reduce stealth castings

5. Improving casting quality

6. Reduction of internal defects of re-oxidation of castings

7. Reduce surface defects after processing castings

Performance and Applications

1. Filter-PAL filter is an alumina ceramic product with a three-dimensional network structure through high temperature sintering

2. High strength, erosion resistance, strong adsorption of impurities, can effectively remove tiny inclusions in molten aluminum

3. Widely used in aluminum foil roll casting blanks, production of aluminum and automotive hubs casting blanks

4. Higher applicability and cost-effectiveness

Information about the company

AdTech manufactures materials and provides services for high temperature filtration and purification with strong technical strength and control system. AdTech is located in Wen County, China, which covers an area of over 20 acres with 20,000 square meters of workshop and warehouse. AdTech serves customers from dozens of countries and regions, including China (China Aluminum Industry, Zhongwang China, Weiqiao, Midas), the Middle East (Bahrain aluminum, Dubai aluminum, Midal cables), Southeast Asia (metal press, GVA, Jindal,) and Europe (hydro, Rusal), etc. AdTech has established long-term relationships with a number of world-famous enterprises. AdTech is a global provider and provider of high-end online degassing and high-temperature filtration and material purification solutions for the high-precision aluminum foundry industry.

Questions and answers

1. Q: Are you a factory or a trading company?

A: we are a factory which was founded in 2012

2. Q: What are your main products?

A: We have been producing online degassing, filtration equipment, ceramic foam filter, hot casting materials, nozzle, Repair coating material and flow abroad for many years.

3. Q: How can you control the quality?

A: For each product processing, we have a complete quality control system for chemical composition and physical properties. After production, all products will be tested, and we have quality certificates with ISO9001 / ISO14001 / SGS.

4. Q: What payment term can you accept?

A: T / T or L / C

5. Q: How can I get samples?

A: We are honored to offer you samples.

6. Question: Does your company accept customization?

A: we accept OEM service.

7. Q: can we visit your company?

A: Yes, of course, you can visit our company.

In filters, polyurethane foam is used as a matrix, which allows to prolong the procedure by catalysis. To this end, the foam is treated with a special ceramic suspension, after which it is dried. Billets with different geometric shapes are supplied to special equipment in which the polyurethane foam matrix burns, leaving the base of the cellular type of finished ceramic products.

The mesh structure of the ceramic foam filters ensures reliable disposal of impurities. Productive filtration can be achieved even under conditions of impressive metallostatic pressure. Ceramic foam filters cannot be dispensed with during both primary and secondary melting processes. They are also installed in aluminum smelting units.

The main functions of foam filters include:

Purification of molten compounds from additives of metallic as well as non-metallic nature.

Reducing the number of oxides.

Increased fluidity of the material.

Get rid of various flaws in the metal.

Improving the quality of casting due to changes in mechanical parameters.

The unique mesh structure of filters created from polyurethane foam, they are highly effective in performing filtration, when compared with other filters involved in the foundry sector.

Ceramic foam filters demonstrate a high level of resistance to the influence of high temperature conditions, they easily absorb molten metal substances. Due to the excellent strength properties, such products can be used even without mounting auxiliary metal screens.

In filters, polyurethane foam is used as a matrix, which allows to prolong the procedure by catalysis. To this end, the foam is treated with a special ceramic suspension, after which it is dried. Billets with different geometric shapes are supplied to special equipment in which the polyurethane foam matrix burns, leaving the base of the cellular type of finished ceramic products.

The mesh structure of the ceramic foam filters ensures reliable disposal of impurities. Productive filtration can be achieved even under conditions of impressive metallostatic pressure. Ceramic foam filters cannot be dispensed with during both primary and secondary melting processes. They are also installed in aluminum smelting units.

The main functions of foam filters include:

Purification of molten compounds from additives of metallic as well as non-metallic nature.

Reducing the number of oxides.

Increased fluidity of the material.

Get rid of various flaws in the metal.

Improving the quality of casting due to changes in mechanical parameters.

The unique mesh structure of filters created from polyurethane foam, they are highly effective in performing filtration, when compared with other filters involved in the foundry sector.

Ceramic foam filters demonstrate a high level of resistance to the influence of high temperature conditions, they easily absorb molten metal substances. Due to the excellent strength properties, such products can be used even without mounting auxiliary metal screens.

Main characteristics of ceramic foam filter

AL2O3 content: 85 - 90%

Porosity: 75 ... 8%

Sizes: 10 '' ... 26 ’’ (production of the filter under the Customer is possible)

Porosity, PPI: 10 ... 70

Bending Strength: approx. 1.5 MPa

The density of the material: 2.2 g. / cm3

Operating temperature: + 1000 - 1200 оС

Main advantages of the Ceralu filter:

Uniform pore structure

High surface strength (less “snow” in the package)

High operating temperature, up to 1150 ° С

High chemical inertness to reagents. used in foundry and k. aggressive aluminum melts (8xxx alloy)

Cerapor LD series ceramic foam filter has been successfully used for casting aluminum. Cerapor LD series filters can be used to cast all common aluminum casting alloys.

Filters of the Cerapor LD series are made of quartz-based material using silica as a binder, have a density slightly lower than that of liquid aluminum (lower by 0.4 g / cm3), i.e. the filter is always on the surface of the liquid metal.

Main technical data of the Cerapor LD filter:

Filter size: 40 * 40 ... 100 * 100 mm (round - D40 ... D100 mm)

Porosity, PP: I 10 ... 30

Thickness: 22 (15) mm

Special shapes and sizes are available to order.

Main characteristics of ceramic foam filter

AL2O3 content: 85 - 90%

Porosity: 75 ... 8%

Sizes: 10 '' ... 26 ’’ (production of the filter under the Customer is possible)

Porosity, PPI: 10 ... 70

Bending Strength: approx. 1.5 MPa

The density of the material: 2.2 g. / cm3

Operating temperature: + 1000 - 1200 оС

Main advantages of the Ceralu filter:

Uniform pore structure

High surface strength (less “snow” in the package)

High operating temperature, up to 1150 ° С

High chemical inertness to reagents. used in foundry and k. aggressive aluminum melts (8xxx alloy)

Cerapor LD series ceramic foam filter has been successfully used for casting aluminum. Cerapor LD series filters can be used to cast all common aluminum casting alloys.

Filters of the Cerapor LD series are made of quartz-based material using silica as a binder, have a density slightly lower than that of liquid aluminum (lower by 0.4 g / cm3), i.e. the filter is always on the surface of the liquid metal.

Main technical data of the Cerapor LD filter:

Filter size: 40 * 40 ... 100 * 100 mm (round - D40 ... D100 mm)

Porosity, PP: I 10 ... 30

Thickness: 22 (15) mm

Special shapes and sizes are available to order.

Kin Ceramic Filters Company Short description

Zirconium is the most famous advanced ceramic material widely used in automotive, petrochemical, fluid control, transmission materials, industrial, electrical and electronic, and semiconductor.

Sapphire is a single crystal alumina.

The ceramic foam filter is a highly efficient molten metal filter.

The three-dimensional structure of the mesh skeleton and its high porosity make it have many advantages, a large slag collection area, a large internal filtration area, low flow resistance, and good filtration effects.

Kin Ceramic Filters Company Characteristics

1. Purification of molten metal fluid, simplified gating system

2. Improve the metallurgical structure of castings and reduce the performance of castings

3. Improve the quality of castings and reduce the internal defects of reoxidation of castings

4. Reduce surface defects after casting

Kin Ceramic Filters Company Short description

Zirconium is the most famous advanced ceramic material widely used in automotive, petrochemical, fluid control, transmission materials, industrial, electrical and electronic, and semiconductor.

Sapphire is a single crystal alumina.

The ceramic foam filter is a highly efficient molten metal filter.

The three-dimensional structure of the mesh skeleton and its high porosity make it have many advantages, a large slag collection area, a large internal filtration area, low flow resistance, and good filtration effects.

Kin Ceramic Filters Company Characteristics

1. Purification of molten metal fluid, simplified gating system

2. Improve the metallurgical structure of castings and reduce the performance of castings

3. Improve the quality of castings and reduce the internal defects of reoxidation of castings

4. Reduce surface defects after casting